| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|

HEAT TRANSPORT OVERVIEW:

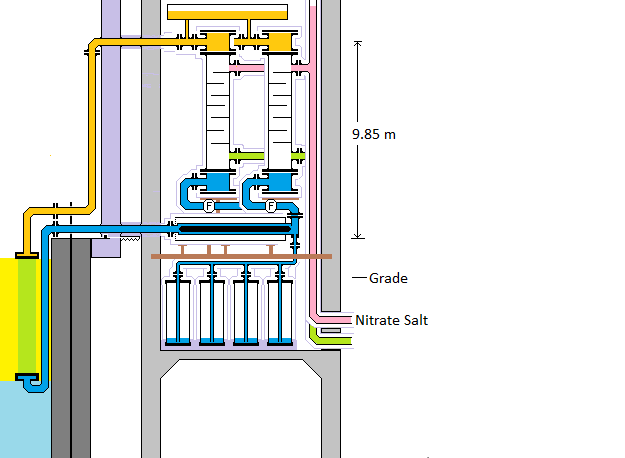

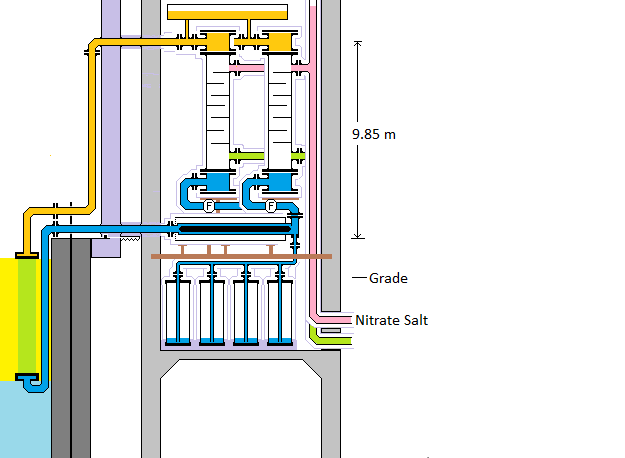

In a liquid sodium cooled Fast Neutron Reactor (FNR) for safety purposes there are isolated NaK and nitrate salt heat transport loops between each immersed intermediate heat exchange bundle and the corresponding steam generator. There is an induction type circulation pump in the NaK return pipe from the NaK-salt heat exchanger to the intermediate heat exchange bundle.

The purpose of the FNR NaK-salt heat exchanger is to transfer heat from the NaK to the nitrate salt while limiting NaK low return temperature excursions.

The NaK/nitrate salt heat exchangers are physically staggered in the Heat Exchaange Galleries so as to allow a maximum heat exchanger flange plus insulation OD of about 104 inches (2.64 m) in a space otherwise width resticted to about 77.3 inches (1.963 m).

The electricity output from a FNR is controlled by modulating the flow rates of the NaK and the nitrate salt.

This web page is concerned with design detail related to the NaK-salt heat exchanger.

Specifications:

Shell OD = 48 inches

Shell length = 6 m

Flange OD = 72 inches

Flange class = 300 pound

Total Feed Pipe open area = Pi (8.625 inch)^2

Overall tube length = 6.0 m

Tubes: 3 / 4 inch ID, 7 / 8 inch OD

Tube center to center distance = 1.25 inch

27 tracks

Tubed diameter = 27 X 1.25 inch = 33.75 inch

Number of tubes = 1 + 6(1 + 2 + 3 + ...+ 12 + 13) = 1 + 6(6)(13) + 6(13) = 1 + (7)(6) (13) = 547

Tube Open area = 547 X Pi X (3 inch / 8)^2 = 76.922 Pi inch^2 = Pi (8.77 inch)^2

Obstructed area of shell = 547 X Pi X (7 / 16)^2 inch^= Pi (104.699 inch^2) = Pi (10.232 inch)^2

Shell thickness = 0.5 inch

Open area of shell = Pi(23.5 inch)^2 - Pi(10.232 inch)^2 = Pi (552.25 inch^2 - 104.69 inch^2) = Pi (447.55 inch^2)

Contained volume of NaK in tubes

= 567 X Pi (3/ 8 inch)^2 X 6 m X (.0254 m / inch)^2

= 1.0209 m^3

Contained volume of NaK in two manifolds

= 2 X 1.0 m X Pi (47 inch / 2)^2 X (.0254 m / inch)^2

= 2.239 m^3

Total NaK in NaK-salt heat exchanger

= 1.0209 m^3 + 2.239 m^3 = 3.2595 m^3

Contained salt volume in NaK-salt heat exchanger:

= [Pi (47 inch / 2)^2 X (0.0254 m / inch)^2 X 5.9 m]

- [Pi (7 /16 inch)^2 X (0.0254 m / inch)^2 X 5.9 m X 547]

= Pi (0.0254 m / inch)^2 X 5.9 m [552.25 inch^2 - 104.699 inch^2]

= 5.352 m^3

The nominal heat transfer area is:

Pi (0.75 inch)(.0254 m / inch) X 5.9 m / tube X 547 tubes

= 193.145 m^2

A FNR NaK-salt heat exchanger is in essence a vertical tube in shell heat exchanger with nitrate salt flowing upward on the shell side and NaK flowing downward inside the tubes. The tubed section is 6m tall and each end manifold is 1 m tall exclusive of the end cover. A FNR NaK-salt heat exchanger and its support equipment must be designed so that a tube rupture anywhere in the heat transport system does not create a dangerous situation due salt or brine entering the NaK circut, mixing with the NaK and instantaneously producing large amounts of hydrogen and/or nitrogen gas.

Due to:

a) The higher heat capacity of salt as compared to NaK;

b) The changes in temperature of the NaK and the salt in normal operation;

the downward NaK volumetric flow rate in the NaK-salt heat exchanger is much higher than the upward volumetric salt flow rate. Thus the salt operates in a laminar flow regime and the NaK flow is turbulent. The heat exchange tube metal adopts the NaK temperature and the heat transfer is mainly a function of the molten salt properties and the molten salt flow rate.

The NaK is normally at a significantly higher pressure than the molten salt, which at the NaK-salt heat exchanger is only slightly above atmospheric pressure. The NaK pressure head is maintained by a argon filled cushion tank which contains a small amount of reserve NaK.

The NaK is hottest in the top manifold of the NaK-salt heat exchanger and flows almost straight downwards inside the tubes. The molten salt is coolest on the bottom of the NaK-salt heat exchanger above the loweer manifold and flows upwards in a zig zag pattern set by internal flow baffles. The high thermal conductivity of the NaK minimizes heat transfer limitations due to laminar NaK flow.

Outside the NaK-salt heat exchanger the salt inlet and discharge pipes both go straight down to below the bottom of the NaK-salt heat exchanger before heading below grade toward the steam generator. The salt discharge pipe from the NaK-salt heat exxchanger has a tee going to a tall vertical vent to the atmosphere via a top ball check. This pipe allows emergency gas and molten salt discharge.

In the event of a NaK-salt heat exchanger tube failure the higher pressure NaK flows into the nitrate salt where it immediately generates nitrogen gas. This gas is at a lower pressure than the NaK, so there is no danger of salt flowing through the tube rupture and into the NaK loop.

The salt circuit has a large vent immediately above the NaK-salt heat exchanger. This vent rapidly fills with nitrogen gas which forces some salt out the aforementioned vent to the atmosphere.

Eventually the NaK loop loses its pressure by discharge of NaK and/or argon through the NaK-salt heat exchanger tube rupture.

However, by then due to salt drain down the salt side of the NaK-salt heat exchanger is filled with nitrogen gas, not salt. Hence there is no danger of salt back flowing into the NaK loop.

In the event of an intermediate heat exchange tube failure the argon pressure in the cushion tank over the NaK loop will cause the NaK to flow through the rupture in the intermediate heat exchange bundle and into the sodium pool.

As soon as a sensor which monitors the NaK level in the NaK cushion tank detects a drop in the NaK level a valve opens which allows air to escape from the nitrate salt dump tanks. The nitrate salt immediately drains down into its dump tanks. When the nitrate salt level falls below the elevation of the NaK-Salt heat exchanger atmospheric pressure argon is released from the NaK dump tanks and is admitted into the top of the NaK loop. This argon causes the NaK to flow to its dump tank. Hence, even if there is a simultaneous failure of tubes in both the intermediate heat exchanger and the NaK-salt heat exchanger there is still no danger of salt back flowing from the salt circuit into the NaK loop.

Connected to the cushion tank of the NaK loop is a rupture disk venting into the sodium pool space via a liquid catch bucket. This pipe arrangement protects the NaK loop from failure due to over pressure.

The NaK-salt heat exchanger lower manifold cover has a small drain plug to allow drainage of trapped NaK from that manifold when service access inside that manifold is required.

The NaK-salt heat exchanger consists of three stacked coaxial sections. Starting from the bottom:

1) A 1 m high bottom manifold which discharges the cool NaK to a 18 inch OD schedule 40S pipe. This section has schedule 40S fittings;

2) A 6 m high middle tube section where the rising salt in the shell is heated by the falling NaK in the tubes. This section has

8.625 inch OD schedule 40S molten salt bottom inlet and top discharge pipes. After the tee this discharge pipe immediately enlarges to a 16 inch vent to the roof which is fitted with a top ball check.

3) A top manifold which inputs hot NaK from a 18 inch OD schedule 40S inlet pipe and distributes it to vertical tubes.

An important aspect of this heat exchanger design is the perimeter portions of the tube sheets that are untubed to allow the tube sheet to flex with temperature. The issue is that the tubes will run hotter than the shell causing the tubes to expand more than the shell. The tube sheets must flex to absorb the resulting differential thermal expansion.

FNR NaK-SALT HEAT EXCHANGER PRESSURE ISSUES:

The NaK circuit is pressure limited by the 24 inch tube of the induction pump which has a 0.375 inch wall thickness. At the working temperature the maximum allowable hoop stress in stainless steel is 39 MPa. The corresponding maximum NaK pressure Pm is given by:

Pm (24.000 inch - 2(0.375 inch)) L = 39 MPa [2 (0.375 inch) L]

or

Pm = 39 MPa (0.750 inch) /23.25inch

= 1.26 MPa

Thus the entire NaK circuit should be rated for a maximum working pressure of: (2 / 3) X 1.26 MPa = 0.84 MPa. The NaK loop should be subject to a 1.26 MPa hydraulic pressure test.

The 48 inch OD NaK-salt heat exchanger end manifolds form part of the NaK circuit. Let Wm be the manifold side wall thickness. Then for

Pm = 1.26 MPa

1.26 MPa (48.0 inch - 2 W) = 39 MPa (2 W)

or

2 W (39 MPa + 1.26 MPa) = 1.26 MPa (48.0 inch)

or

W = 1.26 MPa (48.0 inch) / 2 MPa (40.26)

= 0.7511 inch

The tubes in the NaK-nitrate salt heat exchanger form part of the NaK circuit. Choose the tube ID = 0.7500 inch. Then for the stainless steel tubes the minimum wall thickness Wt is given by:

1.26 MPa (0.7500 inch) = 39 MPa (2 W)

or

W = 1.26 MPa (0.7500 inch) / 39 MPa (2)

= 0.0121 inch

In practise real tubes have a wall thickness of 0.0625 inch, several times that wall thickness, so the probability of tube failure in the NaK/nitrate salt heat exchanger is very low.

In normal operation the NaK/nitrate salt heat exchanger end manifolds contain NaK which is at a moderate pressure(0.5 MPa).

NaK-NITATE SALT HEAT EXCHANGER SHELL SIZE CALCULATION:

Assume that the NaK-salt heat exchanger has a tube bundle 6 m long consisting of 0.7500 inch ID, 0.875 inch OD tubes on 1.25 inch staggered centers. The NaK-salt heat exchanger shell is 48 inch OD.

Since the shell side of the NaK-salt heat exchanger is vented to the atmosphere the shell side pressure is very low and is primarily the result of ~ 8 m of nitrate salt head.

Consider a cylindrical shell with an outside diameter of 48 inches. Barlow's formula gives the maximum working pressure Pm as:

Pm = [2 Sy W] / [3 D]

where:

Sy = yield stress

W = wall thickness

D = inside diameter

or

[3 Pm / 2 Sy] = [W / D]

However for this example:

D + 2 W = 48 inch

or

D = 48 inch - 2 W

or

W / D = W / (48 inch - 2 W)

giving:

[3 Pm / 2 Sy] = W / (48 inch - 2 W)

or

(48 inch - 2 W)[3 Pm / 2 Sy] = W

or

W [1 + 2 (3 Pm / 2 Sy)] = 48 inch (3 Pm / 2 Sy)

or

W = 48 inch (3 Pm / 2 Sy) / [1 + 2 (3 Pm / 2 Sy)]

In the case of the NaK-nitrate salt heat exchanger end manifolds where:

Pm = 1.26 MPa

Sy = 117 MPa

[3 Pm / 2 Sy] = [W / D]

= 3.78 MPa / 234 MPa

giving:

W = 48 inch (3 Pm / 2 Sy) / [1 + 2 (3 Pm / 2 Sy)]

= 48 inch (3.78 MPa / 234 MPa) / [1 + 7.56 MPa / 234 MPa]

= 48 inch [(3.78 /234) /(1.0323]

= 0.7511 inch

Hence the manifold wall thickness should be 0.75 inch

Recall that as shown in FNR Heat Transport System the thickness T of a solid end cap is given by:

T = D [3 P / 8 Sy]^0.5

= 48 inch [3 (1.26 MPa) / 8 (117 MPa)]^0.5

= 48 inch [0.0635]

= 3.05 inch

The NaK/nitrate salt-salt exchanger tubes normally contain liquid NaK at ~ 0.5 MPa. After fabrication the tube side of the sodium-salt heat exchanger should be hydraulic pressure tested at 1.26 MPa.

The shell side of the NaK/nitrate salt heat exchanger is filled with molten nitrate salt which is normally at atmospheric pressure. We must be concerned about thermal stress arising from a tube temperature that is greater than the shell temperature.

Assume that each tube is 7 / 8 inch OD. Then the tube wall thickness is:

[(7 / 8 inch) - (3 / 4 inch)] / 2 = (1 / 16 inch) = 0.0625 inch

For this tube size the single tube metal cross sectional area is:

Pi [(7 / 16)^2 - (3 / 8)^2] inch^2

= Pi [49 / 256 - 36 / 256] inch^2

= Pi [13 / 256] inch^2

Thus the cross sectional area of the tube walls is:

547 tubes X Pi (13 / 256) inch^2 / tube = 87.265 inch^2

The shell wall cross sectional area is:

Pi (48 inch) Ws

where Ws is the shell sidewall thickness.

Recall that the shell wall thickness is Ws = 0.5 inch

Pi (48 inch) Ws = 75.4 inch^2Note that the metal cross sectional area of the shell and the tubes are comparable.

The heat transfer circuit has both NaK and molten salt level sensors. An unanticipated decrease in liquid sodium level indicates either an intermediate heat exchange bundle leak or a NaK-salt heat exchanger leak or a NaK dump tank argon charge leak.

This arrangement can safely absorb transient high pressures in either the NaK circuit or the nitrate salt circuit.

On the occurrance of a steam generator tube failure high pressure water and steam both jet through the rupture into the tubes of the steam generator where they contact nitrate salt and cause a rapid pressure rise in the salt on the steam generator tube side. The rate of the pressure rise is mitigated by:

a)Use of narrow heat exchange pressure tubes which limit the water flow rate into the salt;

b)Use of upward sloping salt pipes which rise to a vent open to the atmosphere.

This pressure relief arrangement protects the NaK-salt heat exchanger from large steam or nitrogen induced molten salt pressure pulses. Note that the 12 inch pipes conveying NaK between the intermediate heat exchange bundle and the NaK-salt heat exchanger are designed so that the pressure differences between the NaK and both the molten salt and the primary sodium are sufficient to prevent either molten salt or primary sodium entering the NaK loop.

The NaK induction pump is located close to the pool deck level to ensure that during NaK loop flow it always has sufficient suction head pressure.

Below the sodium pool deck level are NaK dump tanks for holding NaK to permit heat transport loop maintenance and fire suppression. If the argon pressure over the Nak dump tanks is released the NaK will drain down to the pool deck level. This feature can be used to extinguish a NaK fire.

The NaK argon cover gas is installed with the system cool at an absolute pressure of about 0.2 MPa. This pressure will more than double at normal operting temperature. If the argon pressure rises to 0.8 MPa absolute for even a few milliseconds the loop safety shutdown sequence should be initiated.

It is difficult to realize good high temperature high pressure NaK seals at flanged mechanical joints. Hence normally the NaK operates at about 0.5 MPa gauge pressure. The NaK loop is rated for a higher pressure simply to ensure that there is no major damage when there is a NaK-salt heat exchanger tube rupture or a steam generator tube rupture. It is possible that as a result of a major pressure pulse gasketed flange joints may leak liquid NaK, in which case the NaK must be drained down into its dump tank and the flange joint sealing gaskets replaced. The implication of this is that an intermediate heat exchange tube failure or a sodium-salt heat exchange tube failure may result in that heat transfer loop being out of service until the next reactor shutdown. However, the large number of independent heat transfer loops minimizes the consequence of a single loop shutdown.

There must be protection against both NaK and molten salt hammer in each heat transfer circuit. This objective is achieved by keeping the NaK pressure sufficiently high to prevent both nitrate salt and water from entering the secondary sodium heat transport piping.

The diagram shows that the exposed heat exchange tube length in the sodium-salt heat exchanger is:

5.70 m.

NaK-Salt Heat Exchanger Positioning

The NaK-Salt heat exchangers are positioned on two circles with their centers at the center of the sodium pool.

Let Ri be the radius of the inner circle. The center to center distance between the two exchangers on the inner circle is:

Pi (2 Ri) / 23

This web page last updated December 17, 2023

| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|