| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|

INTRODUCTION:

A nuclear reactor produces heat. That heat is used to produce high pressure (10 MPa), high temperature (> 400 deg C) steam. The steam is expanded through turbines connected to synchronous electricity generators to produce electricity.

This web page describes the sodium-potassium alloy (NaK) loops that transport heat from the FNR liquid sodium pool to the steam generators.

In the described power system the sodium pool temperature is held in the range 470 deg C to 500 deg C by the physical properties of the FNR. The steam generator water temperature is held nearly constant at about 320 degrees C by the steam generator's discharge pressure regulator valve setting.

The NaK loop transports heat from the FNR sodium pool to the steam generator. The NaK loop temperature difference is typically about 120 degrees C at heavy loads and 140 degrees C at light loads. Changing the NaK flow rate changes the rate of heat transport from the sodium pool to the steam generator and hence changes the rate of steam production. An advantage of this system design is that the solid material temperatures remain nearly constant over the system's 10% to 100% power modulation range, which minimizes wear due to changing thermal stress.

In a liquid sodium cooled FNR power plant, due to the chemical incompatibility between sodium and water and due to the radio activity of the sodium, the sodium is double isolated from the steam generator's water/steam. Heat moves from the atmospheric pressure liquid sodium (0.101 MPa absolute at the sodium pool surface) to lower absolute pressure NaK by thermal conduction through the walls of the intermediate heat exchange bundle tubes that are immersed in liquid sodium. A combination of natural convection and induction pumping causes liquid NaK to flow through the intermediate heat exchange bundle tubes, through the radial NaK pipes and through the steam generators. NaK is used because it remains a chemically stable low pressure high thermal and high electrical conductivity liquid from below room temperature up to over 500 degrees C.

The NaK is a fire risk if it is exposed to either air or water. In order to quickly extinguish NaK fires that might occur after a gasket leak or other loop failure each NaK loop is fitted with a dedicated NaK dump tank. When the argon pressure over the dump tank is removed the NaK loop gravity drains into its dump tank.

The NaK loop is designed such that in normal operation, at every point in the NaK loop, other than the branch to the NaK dump tank, the NaK absolute pressure is less than the absolute pressure of the surrounding fluid (air, argon gas, liquid sodium). Hence any small NaK loop leak will cause inward leakage of external fluid, resulting in an increase in the pressure in the vacuum plenum over the NaK and a decrease in the liquid NaK level that can be readily detected. This system design imposes strict limits on the elevations of the steam generator and the induction pump with respect to the sodium pool, the pressure drop across the steam generator tubes and on the elevation of the NaK vacuum plenum.

A small leak anywhere in an intermediate heat exchange bundle will cause radio active Na-24 from the sodium pool to enter the NaK loop, which is normally not radioactive. Any radioactivity in the NaK is easily detected and can trip both an alarm andautomatic NaK drain down.

A small leak in the steam generator tubes will cause water/steam to jet into the NaK via that leak. That water/steam will physically expand and will chemically react with the NaK forming hydrogen gas. The hydrogen gas and steam will raise the pressure in the NaK vacuum plenum, again causing an alarm. This alarm stops the induction pump, stops the injectin pump and opens the steam genertor drain valve. When the pressure in the NaK vacuum plenum substantially exceeds atmospheric pressure a rupture disk opens relieving the over pressure and potentially venting steam and hydrogen to the atmosphere. A ball type discharge check valve prevents air entry. A surge tank should capture ejected NaK. In normal operation the surge tank contains argon to displace oxygen.

On such an alarm, as soon as the steam genertor shell pressure falls below the NaK pressure the NaK should be drained to its dump tank to prevent a possible NaK fire in the corresponding heat exchange gallery.

If there is no radioactivity on the NaK, the location of the NaK loop leak can be found using a He-4 leak detector.

DUMP TANKS:

Below the low point in each NaK heat transport pipe loop are dump tanks that have sufficient volume to store all the NaK in that heat transport loop.

These tanks are physically located in the 2.5 m wide space between the sodium pool outer steel cup and the inside surface of the structural wall. This space will accommodate one 48 inch diameter X 11 m high tank for each heat transport pipe loop. Thus for each heat transport loop the maximum available volume for NaK storage is:

Pi [(6 / 10) m ]^2 X 11 m = 12.44 m^3

Note that the NaK dump tanks must be rated as pressure vessels and must be fitted with high argon pressure relief valves vented to the rooftop surge tank. Note that changing the temperature of the argon over a dump tank affects the argon pressure and hence the NaK column height. Hence each NaK loop needs its own NaK level sensor and argon pressure control for NaK level regulation.

The NaK level control relies on argon pressure control by external low temperature argon valves. To charge a NaK loop argon must be injected into the top of the loop's dump tank while displaced argon in the NaK vacuum plenum is vented to the sodium pool space.

This arrangement requires reliable valves on small argon tubes connected to the dump tank that either vent the dump tank to argon bladder storage or connect pressurized argon to drive NaK out of the NaK dump tank. Note that over time warm NaK vapor may tend to condense in the cooler vent line. This issue may require ongoing maintenance.

NaK LOOPS:

Each heat exchange gallery has an internal width of 8.0 m. Each heat transfer loop has one steam generator. There are 6 such steam generators per heat exchange gallery. The heat transfer loops are spaced at 1.5 m center to center and have 1.25 m off each side. Hence the overall gallery length occupied by equipment is:

5 (1.5 m) + 2 (1.25 m) = 10.0 m.

At the end of the Heat Exchange Gallery furthest from the airlock is the door to the stairwell.

Intermediate heat exchange bundles are immersed in the upper perimeter of the sodium pool. The 16 inch OD Pipes connecting the steam generator manifolds to the intermediate heat exchange bundles go straight through the sodium pool enclosure wall. Each pipe carrying hot NaK from an intermediate heat exchange bundle goes directly to its companion steam generator top manifold inlet port. Each pipe carrying cooler NaK back from a steam generator lower manifold to its companion intermediate heat exchange bundle is routed through a flow meter (F) and then a vertical induction pump, which in normal operation sets the NaK circulation rate and hence the thermal power conveyed by the heat transport circuit. Note that in normal full power operation this NaK circulation rate results in a NaK return temperature of about 330 degrees C.

There is a NaK drain to 1.7 MPa pressure rated NaK dump tanks connected to a low point on the NaK return pipe between the steam generator lower manifold and the induction pump. This drain pipe is connected so as to fully drain the NaK in both the steam generator and the induction pump.

The lower steam generator manifold covers have a small drain plugs to allow drainage of remaining trapped NaK from that manifold when service access inside that manifold is required.

In the event of a steam generator tube rupture the higher pressure water (~ 10 MPa) will enter the NaK loop where it will flash to steam and will rapidly chemically react producing hydrogen. These gases will blow the rupture disks on top of the large diameter NaK loop vents and will discharge H2 and steam out these vents.

Loss of NaK out this vent could potentially start a fire when exposed to air or water.

The steam pressure in the steam generator shell must be set sufficiently high to keep the steam generator water temperature and hence the NaK return temperature at 330 C, above the NaOH melting point. The NaK supply upper temperature is limited by the Na pool temperature. The NaK return temperature should be kept above 320 degrees C to prevent NaOH depositing on heat exchange surfaces. EMERGENCY HEAT REMOVAL:

The steam bypass valve from the steam generator to the turbine condenser is opened. Then the PRV settings are reduced.

Then evaportion of steam generator water will extract heat from the NaK and hence the sodium pool. The steam generator water level control system will automatically add replacement water as the cooling water evaporates.

STEAM GENERATOR TUBE FAILURE:

In the event of a steam generator tube failure the intermediate heat transport fluid (NaK) must behave in a predictable manner to allow safe NaK loop shutdown. However, the NaK loop is presure rated for 1.7 MPa working pressure at 800 degrees K (527 C) to allow safe management of sudden unplanned steam generator tube failures.

The intermediate heat exchange bundles isolate the radioactive liquid sodium from the non-radioactive NaK. A vacuum is applied over the NaK which causes the NaK to operate at a lower pressure than the adjacent Na. Thus, subject to intermediate heat exchange bundle integrity, the heat exchange galleries should be radiation free. In the event of a leak in the NaK loop then Na, Ar or air flows into the NaK loop instead of NaK flowing out the NaK loop. Any radioactivity in the NaK indicates an intermediate heat exchange tube bundle leak. The vacuum supported NaK columns are high enough to ensure good NaK circulation.

If steam generator water leaks into the NaK circuit large volumes of hydrogen will instantly be produced. This hydrogen will be vented via two 16 inch OD vent pipes that terminate in rupture disks. An above normal pressure in the NaK indicates a steam generator tube leak.

If a tube leak is suspected the NaK in the heat exchange gallery and in the sodium pool space above the pool deck should automatically immediately drain down to its respective dump tanks.

Note that with a vacuum over the NaK,the argon gas pressure over the NaK dump tanks sets the top of NaK level.

Both ends of the steam generator NaK loop are potentially vented to the atmosphere via tall large diameter (16 inch OD) vents with ruptue discs and ball checks.

In the event of a steam generator tube leak hydrogen gas will immediately form in the NaK loop and together with steam will violently expel some NaK up the large diameter vents. A top of vent vacuum space, a rupture disc and a ball check are used to minimize discharge of NaK to the atmosphere.

STEAM GENERATOR TUBE FAILURE:

1) Mixing sodium and potasium is crazy

2) In the Youtube video the NaK floated on liquid water and generated hydrogen which then burned in the surrounding air.

3) In a steam generator tube failure superheated liquid water squirts through the tube failure aperture into low pressure NaK. That liquid water instantly flashes to steam and volume expands about 100X.

4) The steam bubble(s) will rise through the hot liquid NaK. The lower molecular density of the steam will slow the hydrogen producing chemical reaction.

5) There is no oxygen present to support hydrogen combustion.

6) The steam and hydrogen will rise through a cyclone separator and be captured by an overhead vacuum tank.

7) Most NaK bits carried along by the hydrogen/steam mix are trapped by the cyclone separator;

8) If the pressure in the vacuum tank exceeds 1.7 MPa a rupture disc opens and the steam and hydrogen are vented to the atmosphere. That vent may involve a water trap. That water trap must be large enough to safely absorb any NaK that escapes from the cyclone separator.

9) A large ball check prevents air backing into the NaK loop when the rupture disc is open.

REACTOR POWER

The reactor power is controlled by controlling the rate of heat extraction which is set by the speed of the NaK induction pumps. The liquid sodium temperature and steam generator water temperature remain nearly constant. This arrangement minimizes thermal stress through the heat transport system with time varying reactor power and protects the induction pump from exposure to high NaK temperature.

HEAT EXTRACTION

The steam bypass valve from the steam generator to the turbine condenser is openned. Then evaportion of steam generator water will extract heat from the NaK and hence the sodium pool. The steam generator water level control system will automatically add replacement water as the cooling water evaporates.

NaK PIPING

Except for parts directly exposed to the neutron flux that are made of HT-9,the NaK piping is executed with 316L stainless steel. The steam generator fuel tubes may be made of Inconel which closely matches the TCE of 316L SS. The issue is that unlike the sodium pool, the NaK can tolerate dissolved nickel. The NaK should contain enough Fe, Ni and Cr to be in equilibrium to minimize long term corrosion of 316L stainles steel. The sodium in the reactor pool contains free neutrons whiich can interact with dissolved nickel causing problems whereas the NaK contains no neutrons. The advantage of Ni is that it strengthens steels at high temperatures.

The NaK dump tanks are charged with sufficient NaK to fill the NaK circulating loop. Then compressed argon is added over the dump tanks to set the NaK level.

The NaK loop piping has 16.0 inch OD with 0.375 inch wall. The NaK loop is rated for a maximum working pressure of 1.7 MPa. The NaK referred to herein is a low temperature melting point alloy consisting of 77% K by weight. A major feature of this NaK is that it is liquid from below room temperature up to over 700 degrees C. This feature enables sodium melting by transfer of heat backward from the steam generators through the NaK to the sodium pool. NaK is not used in the sodium pool due to its inferior neutronic properties as compared to pure sodium.

The intermediate heat exchanger is counter flow and is realized with a single pass vertical tube bundle.

The intermediate heat exchange bundle is partially supported via a diagonal chain containing a steel turnbuckle for length/tension adjustment. Due to the chain angle there is a compressive force transferred to the horizontal Nak piping. This piping is supported by a stand set about 1 m away from the inside edge of the pool deck. This stand consists of a force distribution base about 22 inches long, two vertical threaded rods each about 1 inch OD X 2 m long, 4 X 16 inch pipe saddle fittings, one stand top fitting and 12 nuts for fine height adjustment. The saddle fittings must allow radial pipe sliding as the pipe temperature changes.

As the system temperature increasesthe hot wall moves toward the cool wall. Hence the pipe moves radially through the cool wall. There must be a long stainless steel pipe bellows inside the thermal wall to absorb this major radial pipe motion.

Inside the access space are two external aluminum bellows, each 33 inch diameter with ceramic end pieces to seal the 33 inch diameter holes through the cool wall and the inner structural wall.

The amount of pipe axial compression within the thermal wall is about:

20 m X 1.6 X 10^-5 / deg C X 500 deg C = 16 cm. This requires a 16 inch diameter bellows ______ m long.

The steam generator remains in a fixed position. Hence the pipe radial movement with respect to the inner structural wall is about:

5 m X 1.6 X 10^-5 / deg C X 500 deg C = 4 cm

and the amount of pipe radial movement with respect to the thermal wall is about:

There must be a stabilization arm from the top of the steam generator to the outer structural wall to take up axial force arising from the diagonal chain support of the intermediate heat exchange bundle.

The bottom of the hot wall is welded to the pool deck. Hence the height of the stand and the height of the pipe hole through the hot wall move together. The height of the hole is set by thermal expansion of the pool assembly.The height of the pipe axis through this hole is set by thermal expansion of the NaK loop in the heat exchange gallery.

In terms of radial motion, as the temperature of the pool assembly warms the hot wall approaches the stationary cool wall. The NaK pipe is bonded to the hot wall via a 24 inch diameter X 2 m flexible wound stainless steel fitting. This fitting allows the 16 inch OD pipe up to +/- 4 inches of horizontal pipe axis relative vertical movement. The corresponding vertical movement is:

7.5 m X 1.6 X 10^-5 / deg X 500deg C = 6.0 cm

In terms of radial motion the NaK pipe in effect is bonded to the hot wall.

The hot and cold walls must both have a sufficient hoop stress rating. The internal argon pressure is about:

(4 inch WC)(1 / 32 ft)(1ft/ 12 inch)(14.7 lb / inch^2)(26 m X 1 inch /0.0254 m)

= 2 X 10,000 lb /inch^2 X(minimum thickness)

or

(minimum thickness) = (4 X 14.7 X 26 inch)/ (32 X 12 X.0254 X 2 X 10,000)

= .0156 inch

The hot wall must be thicker due to cylindrical instability.

The intermediate heat exchange bundle top manifold connects to the steam generator top manifold via 16 inch OD schedule 40S stainless steel pipe. The intermediate heat exchange bundle bottom manifold connects to the steam generator tube side bottom manifold via a 16 inch OD schedule 40S stainless steel pipe. This pipe contains an induction pump that circulates NaK from the bottom manifold of the steam generator to the bottom manifold of the intermediate heat exchange bundle. This configuration provides heat exchange counterflow and permits removal and replacement of individual steam generators and induction pumps via overhead crane lifts. There is a gravity drain from the NaK loop to dedicated parallel connected NaK dump tanks. Three vertical vent pipes and a shared vacuum chamber are required for each NaK loop to trap and expel gases and to indicate the NaK levels.

The NaK pipes are supported by steam generator and the induction pump at the heat exchange gallery end and are supported by a diagonal chain fastened high up the pool space wall. This chain contains a section which has a controlled thermal coefficient of expansion. The chain support is chosen so that the intermediate heat exchange bundles remain in a constant position with respect to the corresponding steam generators. The hot wall and the pipe feed through fittings at the cool wall and the structural wall provide negligible NaK pipe and intermediate heat exchange bundle support. Axial compressive stress on the NaK pipes partially supports the intermediate heat exchange bundles and acts to compress the pipe flange seals.

WALL SEALS:

The NaK pipes pass through the hot wall, the cool wall and the inner structural wall. The wall seals must be effective at preventing low differential pressure argon leakage in the presence of changing pipe temperature and pipe axis vertical motion due to thermal expansion/contraction of the steam generator and the hot wall. It is necessary to design the pipe support to minimize temperature driven vertical movement of the pipe axis with respect to the hot wall hole axis. For example, when the system is cooled from 500 degrees C to 120 degrees C for service the change in elevation of the pool deck is driven by a changing temperature SS height of 17 m whereas the change in elevation of the NaK hot pipe at the steam generator is driven by a changing temperature SS height of 7 m, so NaK pipe vertical translational movement with respect to the axis of holes through the hot and cool walls is a potential problem. At the extreme the pool is hot whereas the steam generator is cold. That condition causes a NaK pipe axis relative vertical displacement with respect to the hot wall hole of:

20 m X 500 deg C X 16 X 10^-6 / deg C

= 0.16 m

= 6.3 inch

HOT WALL NaK PIPE PASSAGE

Each NaK pipe passage through a hot wall involves a 304L stainless steel split disk 16 inch ID, 28 inch OD field seal welded onto the outside of the 16 inch OD pipe; an interface Seal-On 24 inch ID, 28 inch OD fastened to the split disk; a 24 inch diameter flexible stainless steel connection to the hot wall via another 24 inch ID, 28 inch OD interface Seal-On and a round wall adapter plate. At the hot wall the round adapter plate 24 inch ID, 37 inch OD mates the 24 inch ID, 28 inch OD Seal-On to the 33 inch diameter hole in the hot wall. The hot wall is designed to flex to accommodate axial pipe movement because the 24 inch diameter flexible stainless steel connection is axially incompresible.

This flexible stainless steel connection is 24 inch diameter Triple Lock T/L-SS as manufactured by Flexmaster using 316 stainless steel, which allows a total of 8 inches of vertical motion of the pipe axis with respect to the hot wall hole axis but does not allow axial motion of the pipe with respect to the hot wall. To provide that axial motion the surface of the hot wall must bend towards the sodium pool as the pipe temperature increases. This bending is enabled by wall surface thermal expansion and by the wave geometry on the hot wall surface. Hence the hot wall surface has shallow waves with vertical wave fronts. The hot wall sheet material must be sufficiently thin to enable this bending. Note that the pool space enclosed by the hot wall is nominally 26 m in diameter with NaK pipes at:

Pi (26 m) / 56 = 1.45 m intervals

around the hot wall perimeter. Hence the surface wavelength is 1.45 m.

The minimum half length of the flexible stainless steel section between Seal-Ons is set by the requirement for a minimum bending radius of:

2.5 X 24 inch = 60 inch.

A little geometry shows that for a 2 inch deviation over that half length X:

X^2 + (60inch - 2 inch)^2 = (60 inch )^2

or

X^2 = [60^2 - 58^2] inch^2

= (3600 - 3364) inch^2

= 236 inch^2

Hence:

X = 15.4 inch

and the minimum flexible section length subject to curvature is 2 X = 30.8 inch

To this length we must add the straight length of two #20 gauge Seal-Ons:

2 X (24 inch / 2) = 24 inch.

The space between the hot wall and the cool wall above the pool deck is filled with ceramic fiber thermal insulation and argon at a relative pressure of 4 inches WC. The NaK pipes pass through 33 inch diameter holes in the cool wall and the inner structural wall. Inside the thermal wall and the inner structural wall are split insulation sections, each 16 inch ID, 33 inch OD, ~ 1 m long.

COOL WALL PIPE PASSAGE:

The hole through the cool wall is 33 inch diameter. At the cool wall there is an insulation annulus 24 inch ID, 32 inch OD in sections. Around the hole is a steel adapter plate 33 inch ID, 37 inch OD that holds a 33 inch diameter aluminum bellows 33 inch diameter. This aluminum bellows is fastened to a cermic disk 33 inch OD, 16 inch ID. This disk is firmly sealed to the 16 inch OD stainles steel pipe. This seal takes the form of two 16 inch ID X 18 inch OD split rings attached together by screws.

INNER STRUCTURAL WALL PIPE PASSAGE:

The horizontal NaK pipe axis vertical travel, 7

The seal for the inner structual wall is more complex, because in the presence of a tornado this seal must withstand about a 2 psi pressure difference. That 2 psi translates into a total axial force of about:

Pi [33 inch / 2]^2 X 2 psi = 1711 lb.

This axial force is partly absorbed by the inner structural wall and partly becomes a tipping force acting on the steam generator that must be opposed by a stabilization arm to the outer structural wall.

The ~ 20 inch long seal is mounted via the inside of the inner structural wall. Within this structural wall is a 33 inch diameter steel liner with a robust 6 cm wide flat inside lip at its outer end and a robust 33 inch ID, 37 inch OD ring at its inner end. The material within this liner is a bead filled ceramic epoxy ring plug that:

a)Can withstand continuous operation at 500 deg C at its inside radius;

b) Has a low thermal conductivity like fiberfrax;

c) Has a similar TCE as the 16 inch OD stainless steel NaK pipe;

d) Has an impermiable coating applied to its ends.

e) Is cast in place with a 16 inch ID (sliding fit) and a (33 inch - 6 cm) OD.

During a tornado event the high pressure difference across the inner structural wall drives this ring plug hard against the aforementioned inside lip forming a seal for the high differential pressure. At normal times of low pressure difference the 37 inch OD liner ring is sealed to the(33 inch - 6 cm) OD of the sliding ring plug by a textile bellows glue to the inner end perimeter of the ceramic epoxy plug and clamped under the 37 inch OD liner ring.

During normal temperature cycling the ceramic epoxy plug sticks to the stainless steel pipe, sliding back and forth axially about 3 cm and moving up and down about 5.8 cm. The textle bellows must accommodate this movement.

In a tornado, due to the high differential pressure, the ceramic ring plug will slide on the stainless steel pipe to seal. It is likely that the textile bellows will be damaged during a tornado. However, tornados are rare events, so replacement of the damaged textile bellows that are readily accessible from inside the service space should not be a major service problem.

This arrangement provides for the radial, translational and axial pipe movement caused by steam generator, pipe and hot wall thermal expansion/contraction.

PHYSICAL ACCESS:

The spaces between adjacent insulated NaK pipes are too small to permit service access by crawling between pipes. Service space access above the NaK pipes is realized by entering the service space above the airlocks.

RELATIVE AXIAL MOTION ENLARGEMENT:

As the system temperature changes due to differential thermal expansion the sodium pool walls will also move with respect to the intermediate heat exchange bundles. It is important to have enough space around these bundles to allow this relative movement.

MELTING POINTS

NaK melting point = < 15 degrees C

which keeps the NaK liquid over its normal operating temperature range.

NaOH melting point = 318 degrees C

This keeps NaOH liquid during normal reactor operation but permits NaOH removal by cooling and filtering.

KOH melting point = 406 degrees C.

This keeps KOH liquid on the hot side of the NaK loop but permits continuous removal via a shunt filter across the induction pump.

Na2O melting point =

K2O melting point =

DENSITIES:

Na = 971 kg / m^3

K = 856 kg / m^3

Reference Wikipedia Sodium-Potasium alloy.

NaK containing 40% to 90% K by mass is liquid at room temperature.

NaK-77 eutectic contains 23% Na and 77% K by mass and is liquid over the temperature range -12.5 C to + 785 degrees C.

DENSITY OF NaK-77 (77% K):

866 kg / m^3 at 20 degrees C

855 kg / m^3 at 100 degrees C

749 kg / m^3 at 550 degrees C

By interpolation density at 450 degees C is:

855 kg /m^3 - (350 / 450)(855 - 749) kg / m^3

= 855 Kg / m^3 - 82.44 kg / m^3

= 772.55 kg / m^3

The NaK eutectic column height H certain to be supported by one atmosphere is given by:

Rho g H = 101,000 Pa

or

H = 101,000 Pa/ [866 kg / m^3 X 9.8 m / s^2]

= 11.90 m

Hence the maximum NaK height at no NaK flow is 11.9 m above the bottom of the lower steam generator manifold.

At full flow the maximum NaK height above the liquid sodium pool surface is 11.9 m.

Hence the NaK column height available to accommodate flow induced pressure drops through the NaK loop is the difference in elevation between the sodium pool surface and the bottom of the lower steam generator manifold which is:

7.5 m - 2.5 m = 5 m

Expressed in pressure that is:

(5 m / 11.9 m) X 101,000 Pa = 42,437 Pa

We need to compare this driving differential pressure to the sum of the differential NaK flow induced pressure drops across the intermediate heat exchange bundle, the steam generator, the induction pump and the NaK loop piping.

HEAT CAPACITY OF NaK:

= 982 J / (kg-deg C)

NaK FLOW RATE:

At full power each NaK loop transports 20.8 MWt = 20.8 X 10^6 W = 20.8 X 10^6 J / s

Assume that at full power the NaK loop temperature drop falls to 100 deg C.

(20.8 X 10^6 J / s) /[(982 J / kg-deg C)X 100 deg C] = 211.81 kg / s

(211.81 kg/ s) / 772.55 kg / m^3 = 0.274 m^3 / s

THEORETICAL REQUIRED FULL FLOW PUMPING POWER:

Assume that the NaK loop flow induced pressure drop is as much as:

42,437 Pa.

The theoretical minimum power required tochieve this NaK circulation is:

42,437 Pa X 0.274 m^3 / s = 11,628 (kg / m-s^2) (m^3 / s)

= 11,628 kg m^2 /s^3

= 11,628 W

= 11.628 kW

If the induction pump is only 20% efficient this pump load would be:

5 X 11.628 kW = 58.14 kW

THEORETICAL FLOW INDUCED PRESSURE DROPS:

(differential pressure) X (area) X (velocity) = (mass flow rate) X (velocity)^2 / 2

(mass flow rate) = (volumetric flow rate) X (density) = (velocity) X (area) X (density)

Hence:

(differential pressure) X (area) X (velocity) = (velocity) X (area) X (density) X (velocity)^2 / 2

or

(differential pressure) = (density) X (velocity)^2 / 2

= [(density) / 2] X [(volumetric flow rate) / (area)]^2

(density) = 866 kg / m^3

(volumetric flow rate) = 0.274 m^3 / s

Thus:

(differential pressure) = (density) X (velocity)^2 / 2

= [(density) / 2] X [(volumetric flow rate) / (area)]^2

= [(866 kg / 2 m^3) X (0.274 m^3 /s)^2 / (area)^2

= (32.508 kg m^3 / s^2) / (area)^2

From FNR Induction Pump the open annulus cross sectional area of the induction pump is:

Pi (9 inch - 0.375 inch)^2 - (7.0 inch)^2]

79.767 inch^2

= 0.05146 m^2

Induction pump differential pressure drop:

32.508 kg m^3 / s^2) / (throat area)^2

= 32.508 kg m^3 / s^2) / (0.05146 m^2)^2

= 12,276 Pa

Steam Generator differential pressure drop:

32.508 kg m^3 / s^2) / (tube open area)^2

= 32.508 kg m^3 / s^2) / (198.91 inch^2)^2

= 32.508 kg m^3 / s^2) / [(198.91 inch^2 X (.0254 m / inch)^2]^2

=32.508 kg m^3 / s^2) / [(0.1283 m^2)]^2

= 1974.86 Pa

Intermediate heat exchange bundle differential pressure drop:

32.508 kg m^3 / s^2) / (tube open area)^2

= 32.508 kg m^3 / s^2) / (241.65 inch^2)^2

= 32.508 kg m^3 / s^2) / [241.65 inch^2 X (0.0254 m / inch)2]^2

= 32.508 kg m^3 / s^2) / [0.1559 m^2)]^2

= 1337.5 Pa

For a straight piece of 16 inch OD pipe connecting two elbows or manifolds:

(area) = Pi (8 inch - 3 / 8 inch)^2 X (0.0254 m / inch)^2

= 0.1174 m^2

Hence straight pipe differential pressure is:

32.508 kg m^3 / s^2) / (tube open area)^2

= 32.508 kg m^3 / s^2) / (0.1174 m^2)^2

= 2358.6 Pa

This pressure drop, even if repeated 6X due to elbows and manifolds, is still results in a total NaK flow induced loop pressure drop much less than the maximum available 42,437 Pa.

DRAINDOWN:

The NaK level is kept in place by argon pressure over the NaK dump tank and the top vacuum. Opening a shunt valve between the top of the NaK dump tank and the top of the NaK loop allows most of the liquid NaK to flow by gravity into the NaK dump tank. This is the primary means of NaK fire suppression.

Na, K PROPERTIES:

Na density = 0.971 g / cm^3

Na BP = 880 C

K density = 0.856 g / cm^3

K BP = 760 deg C

Note that the vapor pressure of K is higher than the vapor pressure of Na, which will limit the possible minimum vapor pressure at 500 degrees C.

SPECIFIC GRAVITY:

If there is a steam generator tube failure high pressure liquid water leaks from the steam generator into the NaK loop, the water instantly flashes to steam, hydrogen gas is generated and two gases bubble up therough the NaK. A rapid chemical reaction between the Nak and steam produces H2, KOH and NaOH. The KOH and NaOH may be either liquid or solid, depending on the temperature, but are more dense than NaK and hence sink to the bottom. The steam and hydrogen gas mix raising the pressure and blow out via a vent top rupture disk. The rapidly rising pressure closes the top ball check to the vacuum pump that otherwise evacuates argon, potassium vapor and sodium vapor to a cold trap for material recovery.

INDUCTION PUMP SUCTION HEAD REQUIREMENT:

From FNR Induction Pump the open annulus cross sectional area of the inductioon pump is:

Pi (9 inch - 0.375 inch)^2 - (7.0 inch)^2]

79.767 inch^2

= 0.05146 m^2

The axial flow velocity through this annulus is:

(0.274 m^3 / s) / 0.05146 m^2 = 5.324 m / s

differential pressure) X (area) X (velocity) = mass flow rate X (velocity)^2 / 2

(mass flow rate) = (volumetric flow rate) X (density) = (velocity) X (area) X density

Hence:

(differential pressure) X (area) X (velocity) = (velocity) X (area) X density X (velocity)^2 / 2

or

(differential pressure) = density X (velocity)^2 / 2

= 866 kg / m^3 X (5.324 m / s)^2 / 2

= 12,276 Pa

= .012276 MPa

Thus the induction pump inlet suction head requirement is easily met.

NATURAL CIRCULATION REQUIREMENT:

There should be enough natural circulation of NaK to remove fission product decay heat. This decay heat is quantified in the paper: Decay Heat In Fast Reactors.

&nnbsp;

NaK NATURAL CIRCULATION:

In normal full load reactor operation the reactor produces 1000 MWt of heat. When the chain reaction is off the reactor may still produce as much as:

0.08 X 1000 MWt = 80 MWt

of fission product decay heat.

After a few ____hours this fission product decay heat output diminishes to about 10 MWt

Hence ideally natural circulation of the NaK should run at over 8% of the maximum pumped circulation rate. Later natural circulation should contnue at 1% of the maximum pumped circulation rate.

The natural circulation rate is primarily limited by the temperature differences between the NaK rising legs and the NaK falling legs and by the viscous flow pressure drops across the intermediate heat exchange bundle and the steam generator. Thus these pressure drops need to be quantified. An important issue is the NaK temperature in the falling leg feeding the intermediate heat exchange bundle. This leg needs to be well insulaed to promote natural circulation. There is a fundamental problem that to support a NaK pressure less than ambient in the sodium pool space the top of the steam generator needs to be not far above the pool deck. That is not a favorable position from a natural NaK circulation perspective.

However, a desirable feature of a low positioned steam generator is that in an emergency part or all of it can readily be flooded with water by gravity so as to achieve removal of fission product decay heat without requiring electrical power. This is a very important safety issue.

NaK THERMAL SIPHON:

Assume emergency cooling conditions when Na temperature = 450 degrees C and steam generator temperature = 100 degrees C. There is loss of house power and hence induction pumping has stopped.

The differential pressure established by the different temperature NaK columns under emergency cooling conditions is:

P = [(855 - 772) / 2] kg / m^3 x 10 m x 9.8 m / s^2

= 4067 kg m / s^2-m^2

Note the divide by 2 due to only partial heating and cooling in the intermediate heat exchange bundle and in the steam generator under emergency thermal siphon conditions.

Neglecting viscosity:

P = Rho V^2 / 2

or

Pb / Pa = (Vb/Va)^2

or

(Vb / Va) = (Pb / Pa)^0.5

Let Va correspond to normal full flow.

Let Vb correspond to thermal siphon flow.

Then:

(Vb / Va) = (4067 Pa / 54,713 Pa)^0.5

= 0.2726

Hence the emergency thermal siphon NaK flow is at least 27% of full NaK flow which is more than sufficient for removal of fission product decay heat.

Hence, provided that the fission power is zero a thermal siphon can be used to dump FNR supplied fission product decay heat. However, forced circulation NaK must be used if fission reactions continue. If the reactor overheats the fission power should drop to zero reducing the thermal output to just fission product decay heat.

PIPE FITTING DIMENSIONS

NaK Pipe: 16 inch OD = 0.4 m OD

NaK pipe flanges: 32 inch OD = 0.8 m OD

NaK pipe 90 degree elbows: inside radius = 16 inch = 0.4 m, outside radius = 32 inch = 0.8 m

NaK pipe 90 degree elbow projection = 32 inch = 0.8 m for pipe, 40 inch = 1 m for flange

NaK pipe 90 degree elbow centerline deviation = 24 inch = 0.6 m

NaK 16 inch X 16 inch X 16 inch pipe tee = 48 inch long

NaK 16 inch X 16 inch X 4 inch pipe tee = 36 inches long

NaK 16 inch X 4 inch X 16 inch elbow tee = 24 inches centerline deviation

10 MPa Steam: 8 inch OD X 6 inch ID, 16 inch flange diameter

10 MPa injection water: 4 inch OD X 3 inch ID, 8 inch flange diameter

PIPE FLANGE JOINTS:

A major constraint on assembly and service of liquid sodium cooled FNRs

is the flanged pipe joints necesssary for repeatedly connecting and disconnecting intermediate heat exchange bundle NaK transport pipes in the field. The assumed solution is precisely machined conflat flanges with chromium or nickel plated copper gaskets. The purpose of the chromium or nickel plating is to prevent the copper dissolving in hot Na and K. As compared to a high vacuum system, minor inward external fluid leakage is acceptable. The vacuum possible is limited by the vapor pressures of Na and K at 500 degrees C.

Copper melting point = 1084.6 degrees C

Chromium melting point = 1906 degrees C

Chromium can be electroplated onto copper.

Nickel melting point = ____ degrees C

Nickel can be electroplated onto copper.

FLANGED JOINT LEAK PREVENTION:

Bolted flange pipe joints are required in the argon filled space over the sodium pool space to enable practical replacement of intermediate heat exchange bundles. The aim of this design is to do all necessary to ensure that everywhere the NaK absolute internal pressure is lower than the surrounding absolute external fluid pressure. Hence if there is any NaK loop leakage in the sodium pool space it is argon or sodium leaking into the NaK, not vice versa. Some of the flanged joints in pipe containing NaK can be perimeter welded for seal certainty.

Above the liquid sodium surface in the sodium pool space the absolute external pressure is set by argon at 0.101 MPa and sodium at ________MPa.

Provided that the NaK absolute pressure at the sodium pool surface is less than 0.101 MPa, then below the sodium pool surface the absolute Na pressure will always be greater than the NaK absolute pressure. This effect occurs because the density of liquid Na is greater than the density of liquid NaK.

When air or argon at 101,000 Pa is the surrounding fluid the maximum NaK column height to a vacuum is:

h = 101,000 Pa / [(866 kg / m^3) X (9.8 m / s^2)]

= 11.9 m

Of this height at no NaK flow about 4 m are actually used. The induction pump induced NaK flow tends to increase the absolute pressure in the NaK feeding the intermediate heat exchange bundle inlet manifold. However, we have about a 7 m NaK head margin to compensate for the flow induced pressure drops.

HEIGHT ISSUES

The horizontal hot pipe axis is 2.5 m above the liquid sodium pool surface, Hence the top of the NaK is:

2.5 m + 0.5 m + 2 m = 5 m above the liquid sodium pool surface. Hence the region where we are concerned about maintaining the NaK at a negative prssure with respect to its environment is at the bottom of the steam generator.

Between the center lines of its NaK connections the steam generator is 7.0 m tall.

There is a 16 inch X 16 inch 90 deg elbow off the induction pump inlet which takes up 24 inches of steam generator axis height.

On top of the induction pump there is 16 inch X 16 inch X 90 deg elbow to the horizontal cold pipe which takes up 24 inches of steam generator axis height.

There is 1.0 m between the axis of the hot horizontal pipe and the axis of the horizontal cold pipe.

Hence the height remaining for the induction pump is:

(7.0 m - 1.0 m - 24 inch) - (24 inch) = 6 m - 48 inch = 4.8 m remaining.

If we allow 16 inches = 0.4 m for the two induction pump end assemblies the remainder is 4.4 m long. That can be divided into 12.5 wound sections each 4.4 m / 12.5 = 0.352 m long.

INDUCTION PUMP DIMENSIONS:

HEAT EXCHANGE GALLERY LAYOUT:

Steam generator shell OD = 48 inch = 1.2 m

Steam generator flange OD = 72 inch = 1.8 m

Between the horizontal NaK hot pipes feeding two adjacent steam generators spaced ~1.6 m = 60 inch apart center to center along the heat exchange gallery axis runs a vertical 16 inch OD vent pipe. There are 4 layers of insulation.

Maximum insulation thickness is:

(64 - 16 - 16) / 4 = 8 inch

At the bottom of this vent is a special twin tee. The centerline to centerline space available for this twin tee is 1.6 m / 2 = 32 inches. Twin tees of normal design need:

(16 inch + 16 inch + 2(8 inch))= 48 inch. We must reduce the Tee's branch radius of curvature to 8 inch for this item.

The steam generator shells are 48 inch = 1.2 m OD excluding insulation. Their flanges are 72 inch = 1.8 m OD. With insulation at the flanges the steam generators are 92 inch OD.

The steam generators are staggered.

The steam generator manifolds have flange connection faces that are 32 inches from the steam generator center line.

Allow 8 inches from the induction pump outer surface to the wall.

Thus the minimum heat exchange gallery width associated with the induction pump and its pipe elbows is:

8 inch + 48 inch = 56 inch.

Allow 8 inches from the wall to the hot pipe 16 inch X 16 inch X 16 inch tee flange.

Allow 24 inches from the hot pipe tee flange to the center of the tee branch. Then the tee is 48 inches long.

Thus the minium heat exchange gallery distnce to the steam genertor centerline associated with the NaK hot pipe is:

8 inch + 48 inch + 32 inch = 96 inch. Add a 24 inch nipple to make the total 120 inch.

The distance from the inner wall to the nearest steam generator centerline via the induction pump is:

8 inch + 24 inch elbow + 24 inch elbow + 32 inch Tee + 32 inch = 120 inch = 3.0 m

The distance between the two lines of steam generator centres is:

[ (2 m)^2 - (1.5 m)^2]^0.5 = [1.75 m^2]^0.5 = 1.323 m ~ 1.4 m = 56 inch_______

Then the distance from the inner wall to the second line of steam generator centers is :

132 inch + 56 inch = 188 inch

Then the distance from the inner wall to the far side steam generator flanges is:

188 inch + 36 inch = 224 inch

The induction pump inlet vents each need a 24 inch long elbow attched to the far side of the lower steam generator manifold from the interior wall. This vent projects 32 inches, Hence the total projction from the inside wall is:

224 inch + 32 inch = 256 inches

Now allow for another 36 inch wide corridor to provide access to the steam valves. Then the total projection to the far edge of the corridor is:

256 inch + 36 inch = 292 inch.

Available gallery width = 8 m = 315 inch. That leave 23 inches for the steam lines near the outside wall. Allowing for 4 inches of steam line insulation leaves a maximum of 15 inch OD for the steam lines.

We need a 40 inch wide access corridor running between the induction pumps and the steam generators. This spacing is realized using 16 inch X 16 inch X 4 inch tee branch that is 40 inches long to connect between the steam generator lower manifold and the elbow feeding the bottom of the induction pump. The 4 inch OD branch goes down to the NaK dump tanks.

Note that space has yet to be allocated for steam valves, steamlines, condensate feed lines, instrumentation and the induction pump discharge vents.

HEAT EXCHANGE GALLERY LENGTH ALLOCATION:

With 72 inch diameter steam generator flanges the heat exchange gallery length requirement is:

5 (1.5 m) + 72 inch = 372 inch

The available heat exchange gallery length is:

10 m = 394 inches.

SUMMARY:

Steam generator shell is 48 inch OD, 6 m long,

Internal pressure = 10 MPa.

Main flange diameter = 72 inch

Steam Generator Manifolds each 1 m tall

Manifold subflange diameter = 32 inch

Pipe connection = 16 inch

Subflange location = 36 inches from steam generator center line

Steam generator tubes are Inconel (Check TCE!!!______) similar to those in the intermediate heat exchange bundle.

During cooling to permit service the NaK is cooled down to less than 110 degrees C and hence cools the sodium pool down to about 120 degrees C, which permits fuel bundle repositioning and intermediate heat exchange bundle replacement.

The steam bypass valve from the steam generator to the turbine condenser is openned. Then evaportion of steam generator water will extract heat from the NaK and hence the sodium pool. The steam generator water level control system will automatically add replacement water as the steam generator contained water evaporates.

The steam generator and the NaK induction pump are located in a heat exchange gallery outside the perimeter of the FNR's sodium pool enclosure. The NaK does not leave the nuclear island.

Note that a normally closed valve is requred for each dump tank system. On loss of house power this valve closes to prevent NaK flowing into the dump tank so as to preserve capability for emergency passive fission product heat removal.

NORMAL NaK FLOW VELOCITY

Now consider a NaK pipe with an inside diameter of 15.25 inches.(16 inch OD, 0.375 inch wall thickness)

The pipe cross sectional area is:

Pi (15.25 inch / 2)^2 X (0.0254 m / inch)^2 = 0.1178 m^2

Now assume a temperature drop across the NaK loop of:

450 C - 330 C = 120 C

Let V be the average axial flow rate of NaK through the NaK pipe. Then the thermal power transported by the NaK loop is:

P = V X 0.1178 m^2 X 0.9215 g / cm^3 X 10^6 cm^3 / m^3 X 120 C X 1.0368 J / g-C

= V X 13.510 X 10^6 J / m

From the reactor design:

P = 10^9 J / 48 s

Thus:

V = P / (13.510 X 10^6 J / m)

= [10^9 J / 48 s] / (13.510 X 10^6 J / m)

= 10^3 m / (48 X 13.510 s)

= 1.542 m /s

which is an acceptable NaK average axial liquid flow velocity.

NaK FILTERING:

FNR POWER CONTROL STRATEGY:

The control strategy is to use a variable speed induction pump to control the generated electric power. The return temperature of the NaK from the steam generator is set by the steam pressure at about 330 dgrees C. controlled at 330 degrees C. Due to the passive FNR temperature control the NaK supply temperature to the steam generator is nearly constant at 450 C.

The NaK return temperature is locked at about 330 C by the superheated water in the steam generator. The NaK supply temperature is locked at about 440 C by the FNR reactivity versus temperature characteristic. The reactor power is controlled by varying the speed of the induction pump. This ame controlsignal is used to set the power level of the steam generator jacket heater.

Note that this control arrangement relies on there always being some flow through the NaK loop to maintain temperature stability which means that normally the reactor output power should not be modulated down to zero. There will always be some natural circulation in the NaK loop due to fission product decay heat.

An advantage of this control strategy is that maintaining a constant high differential temperature across the NaK loop minimizes thermal stress during electric power modulation.

HEAT TRANSPORT LOOP ISOLATION:

There are 48 identical independent heat transport circuits, 6 connecting to each of the 8 heat exchange galleries located around the perimeter of the primary sodium pool. Failure of any individual heat transport circuit does not cause a failure of the whole. Likewise, any electricity generator can be operated at part power using only a fraction of its 6 allocated heat transport circuits.

Each intermediate heat exchanger supplies hot NaK to a dedicated steam generator. Each NaK loop has four parallel connected dedicated NaK dump tanks, a dedicated variable speed induction pump, a dedicated vacuum cushion tank and three dedicated NaK pressure relief vents. Any heat transport circuit can be shut down for service while the other heat transport circuits remain in operation.

Each of eight heat exchange galleries has six associated NaK heat transport loops. Each NaK heat transport loop must have the capacity:

1000 MWt / (6 X 8) heat transport loops = 20.833 MWt / heat transport loop

at a NaK differential temperature of:

100 degrees C to 120 degrees C.

Each heat transfer loop transfers up to 20.833 MWt of heat which in turn can be used to provide:

20.833 MWt X 0.300 = 6.25 MWe

of turbo-electricity generation. Thus the maximum possible system electricity output is limited by the available heat transport circuits to about:

(48) X 6.25 MWe = 300MWe

Each NaK heat transport loop is executed using 16.000 inch OD schedule 40S stainless steel pipe. This pipe has a wall thickness of 0.375 inch and a linear weight of 75 lb / ft.

At full load the differential temperature drop across each NaK pipe loop is about 110 degrees C and the maximum NaK fvolumetric low in each pipe is ~ 0.274 m^3 / s.

NaK DUMP TANK SIZING:

Assume that the NaK dump tanks are made from 48 inch OD, 0.5 inch wall stainless steel pipe.

W = wall thickness = 0.5 inch

S = wall hoop stress

Sy = wall hoop yield stress at 600 deg C = 117 MPa

P = differential pressure

Py = pressure corresponding to Sy

S = [(48 inch - 2 W) / 2 W] P

or

Py = Sy [2 W / (48 inch - 2 W)

= 117 MPa / 47

= 2.489 MPa

Hence the maximum safe working pressure Pw in the NaK dump tank is:

Pw = Py / 3

= 2.489 MPa / 3 = 0.83 MPa

Assume the induction pump has 16 inch OD X 0.25 inch wall material.

Sw = (15.5 inch / 0.5 inch) 0.83 MPa

= 25.73 MPa

which is less than:

Py / 3 = 117 MPa / 3

= 39 MPa.

Note that the dump tanks contain argon volumes that attenuate NaK liquid pressure pulses transmitted along small diameter pipes. .

The cross sectional open area of the proposed NaK dump tank material is:

Pi[47.0 inch /2]^2 X [0.0254 m / inch]^2 = 1.11932 m^2.

Thus the maximum available NaK dump tank volume is:

11 m high X 1.11932 m^2 = 12.1 m^3

The dump tanks should be located against the inner surface of the structural concrete wall so that there is an open corridor between the sodium pool and the dump tanks. Without insulation the dump tanks tanks are 1.3 m wide at tops and bottoms allowing vertical lift removal or horizontal movement long the corridor.

NaK PIPE CONSTRUCTION:

The NaK piping is 16 inch schedule 40S pipe ( 0.375 inch wall).

Assume 90 degree elbows have an 16 inch inside radius of curvature and a 32 inch outside radius of curvature.

The flanges for 16 inch OD pipe are 32 inch OD Insulation thickness = 4 inch

For the cool pipe:

Find distance from pool wall to center of intermediate heat exchange bundle gooseneck riser:

4 + 64 -8 = 60 inch

Hence the manifold centers are on a circle: 20 m - 2(1.5m) = 17.0 m in diameter

The maximum manifold radius permitted by the down pipe and goose neck is:If all of these manifolds are on the same circle they must not clash.

Circle circumference = Pi (17.0 m) = 53.40 m, allowing:

53.40 / 56 = 0.9537 m / intermediate heat exchange manifold = 37.55 inches

Note that the inside edges of the manifolds are on a circle:

20 m -4 m = 16.0 m in diameter

******************************

DUMP TANKS:

At the low points in the heat transport pipe loops are dump tanks with sufficient volume to accommodate all the NaK in that heat transport loop. Note that the NaK dump tanks must be rated as pressure vessels and must be fitted with high pressure argon relief valves vented to the argon atmosphere over the sodium pool. Note that changing the temperature of the argon in the dump tank affects the argon pressure and hence the NaK level. Hence each NaK loop needs its own argon pressure control and NaK level sensor for liquid level regulation.

The NaK level control relies on argon pressure control by external low temperature argon valves. To charge the NaK loop argon is first injected into the top of the dump tanks while the displaced argon in the cushion tank is vacuum extracted to the sodium pool space.

This arrangement requires a reliable valves on small argon pipes connected to the dump tank that either vent the dump tank to the argon atmosphere or connect pressurized argon to drive NaK out of the NaK dump tank. Note that over time NaK vapor may tend to condense in the cooler vent line. This issue may require ongoing maintenance.

The NaK dump tanks are formed from 48 inch outside diameter stainless steel sheet with 0.75 inch thick walls.

REQUIRED NaK VOLUME:

The cross sectional area of the 15.25 inch I.D. pipes is:

Pi (15.25 inch / 2)^2 X (.0254 m / inch)^2

= 0.1178 m^2

The overall length of equivalent 16 inch pipe containing NaK is:

58.35 m.

The equivalent 16 inch OD pipes have a contained NaK volume of:

58.35 m X 0.1178 m^2 = 6.874 m^3

The intermediate heat exchange bundle contains a NaK volume of 1.0595 m^3.

The steam generator contains a NaK volume of 3.3869 m^3.

FIXHence the NaK dump tank capacity must be more than:

6.874 m^3 + 1.0595 m^3 + 3.3869 m^3 = 11.320 m^3

We have not accounted for the vent pipe or drain down pipe volumes. Prudence suggests that we design for some excess NaK dump tank capacity.

OVERALL NaK REQUIREMENT:

The previous calculation indicates that in sourcing NaK we must plan on acquiring:

48 heat transport circuits X 12 m^3 NaK / heat transport circuit = 576 m^3

of NaK.

VACUUM TANK SIZING:

The vacuum tank can be quite small. During normal operation the argon is in the dump tanks at about 1 atmosphere and the vacuum tank is empty. After draindown the NaK is in the dump tanks and argon is in the system at about one atmosphere.

VACUUM PUMP

The vacuum pump must have a long cooled inlet hose that slopes back toward the liquid NaK. NaK vapor that condenses in this hose should run back by gravity to the liquid NaK.

Argon should be pumped to thetop of the dump tanks.

MAINTENANCE:

There is no radioactivity in the heat exchange galleries which allows safe service work or NaK fire suppression in selected heat exchange galleries without causing a total reactor shutdown.

PLAN VIEW

Note the 2.0 m wide space between adjacent heat exchange galleries that is dedicated to the airlocks that are required for moving fuel bundles and intermediate heat exchange bundles from their truck load/unload points into or out of the sodium pool space.

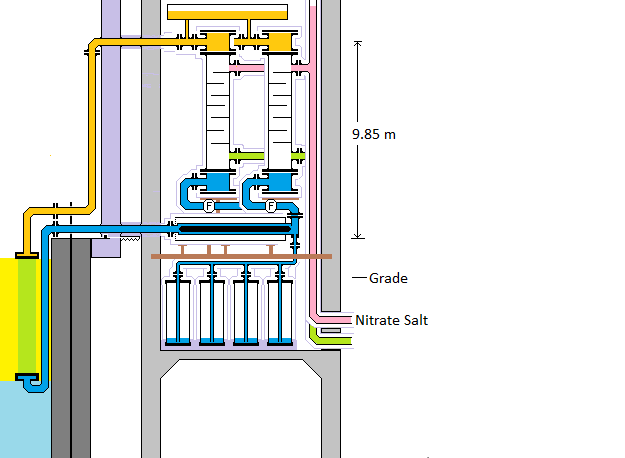

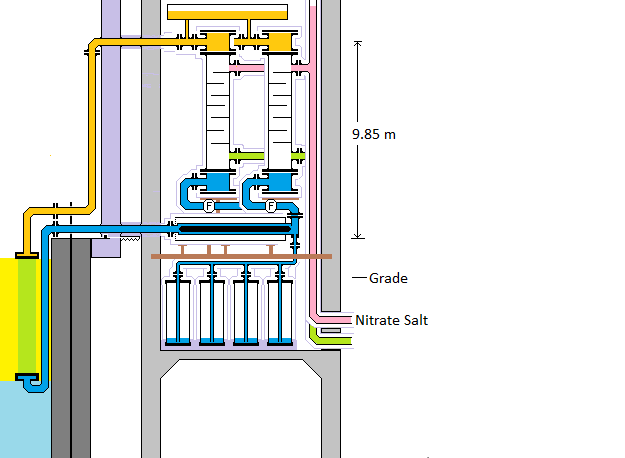

DIAGRAM:

A diagram showing an end view of a heat exchange gallery. Each gallery has 6 heat transport loops, one behind the other. Note that the steam generators are staggered in position, so that part of the 2nd loop is visible behind the first loop.

HEAT EXCHANGE GALLERY:

The left hand side of this diagram shows the intermediate heat exchange bundle and the NaK pipes. This diagram shows the steam generators on the right hand side and the three parallel connected NaK dump tanks in the lower right middle. The vertical induction pump, the NaK flow meter are in the middle of the diagram. Above the steam generator from left to right are the induction pump discharge NaK column, the intermediate heat exchange bundle discharge NaK column and the induction pump inlet NaK column.

Note that steam generator staggering enables a steam generator flange diameter of 72 inch = 1.8 m. Note that the steam generator centerline to end wall clearance is 1.25 m which is sufficient for the steam generator end manifold flanges + insulation with a 48 inch OD steam generator shell.

Each heat exchange gallery has a lower level where the NaK dump tanks are located. Personnel access to the various heat exchange gallery levels is via a stairwell at the gallery end farthest from the airlock truck load/unload point.The disconnects for the NaK induction pumps are wall mounted adjacent to the induction pumps.

Equipment in the heat exchange galleries is installed and removed from above using a mobile crane parked at the airlock truck load/unload point. The roof over the heat exchange galleries must be easily removable and replaceable.

There must be a large air vents in heat exchange galleries for outside air cooling.

An important issue in the heat exchange gallery is isolation of potential NaK drips. Drip collection pans should be provided to isolate dripped NaK. Note that these drips will self ignite in air.

In the basement under each heat exchange gallery and its dump tanks is an isolated service space that is used for an argon bladder. This space is air flow connected to the service access space under the pool deck. Any water penetrating this space must flow along the floor and into the FNR bottom drain located about 18 m below grade.

NaK PIPING:

The intermediate heat exchanger is counter flow and is realized with a single pass vertical tube bundle.

The intermediate heat exchange bundle tube side top manifold connects to the steam generator tube side top manifold via 16 inch OD schedule 40S stainless steel pipe. The intermediate heat exchange bundle bottom connects to the steam generator tube side bottom via a 16 inch OD schedule 40S stainless steel pipe. This pipe contains an induction pump that circulates NaK from the bottom manifold of the steam generator to the bottom manifold of the intermediate heat exchange bundle. This configuration provides heat exchange counterflow and permits removal and replacement of individual steam generators and induction pumps via an overhead crane lift. There is a gravity drain to three parallel connected NaK dump tanks. A small top shared pipe loop is still required for each NaK circuit to trap and expel gases and to indicate the NaK level.

MAXIMUM SAFE NaK WORKING PRESSURE:

For the NaK 16 inch OD schedule 40S pipe used in the induction pump the ID is:

15.25 inch

The NaK pipe wall thickness is:

0.375 inch

Assume that the induction pump barrel is made of SS pipe. A table of 316 SS yield stress versus temperature is as follows:

| TEMPERATURE (degrees K) | YIELD STESS (MPa) |

| 300 | 208 |

| 400 | 167 |

| 500 | 144 |

| 600 | 129 |

| 700 | 122 | 900 | 114 |

| 1000 | 104 |

The highest anticipated NaK working temperature is:

520 C + 273 = 793 K

which from the above table indicates a 316 SS yield stress of 117 MPa.

The corresponding maximum 316 SS working stress is:

117 MPa / 3 = 39 MPa.

NaK PIPING PRESSURE RATING

At 600 degrees C the yield stress of stainless steel is 117 MPa.

Assume the use of 18 inch OD, 17.25 inch ID pipe for the NaK induction pump flow tube. The flow cross sectional area of each such pipe is:

Pi (6.000 inch)^2 X (.0254 m / inch)^2 = 0.07296 m^2

The pipe yield stress at 600 deg C is 117 MPa.

117 MPa X (2) X (0.3750 inch)X L = 87.75 MPa inch L

Hence for safety the NaK pipe working stress should be less than:

117 MPa / 3 = 39 MPa

In the induction pump the OD = 18.00 inch.

The induction pump barrel working pressure at 600 deg C is:

39 MPa X 2 (0.375 inch) = 17.25 inch X P MPa

Hence for safety the NaK pipe working pressure should be less than:

P = 39 MPa X 2 X (.375 inch / 17.25 inch)

= 1.6956 MPa ~ 1.7 MPa

PIPE WALL SEALING AND SUPPORT:

Flexible air and argon bellows wall seals are required at locations where the NaK pipes pass through the inner reactor enclosure wall to accommodate thermal expansion/contraction. Under ordinary operation the reactor power is modulated by controlling the nitrate salt circulation rate and hence the NaK circulation rate. This control methodology causes significant loop differential temperatures.

The NaK pipes and the induction pump must be supported with threaded support hardware so that the pipes and pump remain in their correct positions when an intermediate heat exchanger is disconnected.

NaK TEMPERATURE CONSTRAINTS:

Inside the tubes of the intermediate heat exchange bundle is non-radioactive NaK normally at a pressure less than 0.1 MPa. The normal low temperature limit on the circulated NaK at full load is 330 degrees C to prevent NaOH precipitation on the inside of the tubes within the NaK-salt heat exchanger and to prevent nitrate salt solidification. The normal high temperature limit on the circulated NaK is ~ 460 degrees C. We are assuming a full load 10 degree C temperature difference across the intermediate heat exchange tube bundle wall. At full load the dry steam in the steam generator will reach about:

(460 deg C - 10 deg C -10 C - 40 deg C) = 400 deg C.

At full load the NaK temperature differential is:

450 -330 = 120 deg C

without threat of NaOH precipitation. There is feed water temperature mixing in the lower part of the steam generator to minimize thermal stress on the lower ends of the steam generator tubes. The injection water temperature rise from 25 deg C to 320 C is realized by feed water recuperator heat recovery from the steam immediately upstream from the turbine condenser followed by water mixing in the bottom of the steam generator shell.

TEMPERATURE CONSTRAINT:

At low steam loads the NaK discharge temperature from the intermediate heat exchange bundle will rise to about 459 degrees C. As the steam load increases the NaK discharge temperature from the intermediate heat exchange bundle will decrease to about 450 degrees C.

INDUCTION PUMP THERMAL PROTECTION:

Induction pumps are used to circulate the NaK. The induction pumps must be sized to overcome the flow pressure head in the NaK loops. Note that these pumps should be located on the low temperature return pipes near the primary sodium pool deck level to ensure both cool operation and sufficient positive suction head.

The induction pump operates by inducing a circular current in the liquid sodium. This current crosses a radial magnetic field component and hence experiences an axial force. External 3 phase coils, analogous to the stator coils of a 3 phase AC motor, create a suitable time varying magnetic field.

In normal operation the pumped NaK temperature at the induction pump is in the temperature range 330 degrees C and the induction pumps are oil cooled to protect the electrical insulation from heat damage.

However, under circumstances when the steam generator contains no water the NaK temperature at the induction pump can potentially rise to about 460 degrees C. Under these circumstances the induction pump can easily be damaged if it has insufficient pumped oil cooling. To prevent wide temperature excursions the steam generator shouldbe charged with water before the NaK is transferred from its dump tank back into the NaK heat transfer loop.

Induction pump details are set out at FNR Induction Pump.

GASKET CONSTRAINT:

This FNR operates at too high a (temperature X pressure) product for use of normal elastomeric gaskets. Soft metal or compressed carbon gaskets must be used. Such gaskets do not tolerate pipe misalignment, manifold distortion or high pressures. Hence gasketed mechanical joints need near optical precision fabrication. All the NaK flanges are sealed with such gaskets.The flange bolts must have a smaller TCE than the flange material.

THERMAL EXPANSION:

The steam generators are in fixed positions with respect to the concrete structure. The intermediate heat exchange bundles move radially due to connecting pipe thermal expansion and contraction. Also the above pool deck sodium pool inside wall moves due to thermal expansion. When the system is cold the insulation of the cooler intermediate heat exchange bundle supply pipes should be almost touching the sodium pool inside wall. When the system is hot there is about a 0.2 m gap between this pipe insulation and the sodium pool inside tank wall.

NaK FLOW:

Some of the FNR NaK flow issues are discussed in the paper titled Improving SFR Economics Through Innovation.

The FNR NaK loops take advantage of the relatively large thermal coefficient of expansion of liquid sodium to promote natural circulation of the NaK.

Hence the NaK flow rate for the entire reactor is:

0.274 m^3 / s X 48 = 13.152 m^3 / s

which must be matched by the sodium flow rate.

Herein lies a potential problem. To provide the same heat flux with a 60 degree C sodium temperature differential the total sodium flow must be almost twice as great.

If the total available sodium flow rate through the fuel asembly is less than 26.304 m^3 / s it may constrain the reactor thermal output power.

In normal operation hot (460 degree C) primary sodium flows into the intermediate heat exchange bundles just below the pool surface, flows down outside the intermediate heat exchange tubes and is discharged about 6 m below the primary sodium pool surface at a temperature of about 340 degrees C. Simultaneously NaK flows up inside the intermediate heat exchange bundle tubes, entering at about 330 degrees C and leaving at about 450 degrees C.

The intermediate heat exchange bundles are single pass to realize counter current operation and to minimize material thermal stresses.

In the steam generator NaK flows downwards inside the tubes while water/steamflows upwards in the shell.

Potential fire problems are NaK micro-leaks from the heat transport piping, intermediate heat exchange bundle or induction pump. The NaK pressure driving such leaks is negative. In every case the fire can be extinguished by releasing the argon pressure over the NaK dump tank to the overhead vacuum space which causes gravity drain down of the NaK into the NaK dump tanks.

INTERMEDIATE HEAT EXCHANGE BUNDLES:

The intermediate heat exchange bundles isolate the radioactive liquid sodium from the NaK. The intermediate heat exchange bundle also serve as a barrier to other radioactive species in the event of a fuel tube leak.

To attain the desired full load temperature distribution in the intermediate heat exchanger bundles the NaK mass flow rate must match the sodium mass flow rate. However, the sodium flow cross sectional area is larger so the average sodium linear descent velocity is smaller.

There is a ring of 48 intermediate heat exchange bundles that are immersed in the sodium pool in a 18 m OD, 16 m ID ring. The heat exchange tubes are located between the pool surface and 6 m below the pool surface.

The weight of the intermediate heat exchange bundles is supported by a ring shaped table located in the sodium pool about 8 m above primary sodium pool bottom and 8 m to 9 m radially from the pool center. This table is supported by a ring of steel columns and the table is horizontally stabilized by interleg connections and by the adjacent innermost steel cup sodium pool liner. The top of this table is flat to allow the supported intermediate heat exchange bundles to slide back and forth radially over a distance of about 0.2 m to accommodate thermal expansion/contraction of the sodium pool and the radial NaK piping. Apart from thermal expansion the radial position of the intermediate heat exchange bundles is fixed by the radial NaK pipes which in turn are fixed to the stem generators and induction pumps, which are in turn are fixed to the heat exchange gallery steel and concrete structure. Thermal expansion, at points where these pipes pass through gas tight walls, is accommodated by use of metal bellows fittings.

The maximum outside diameter of the intermediate heat exchange manifolds is limited to:

37.25 inches

so that after accounting for thermal expansion 56 of them will fit in the available space on an 18 m diameter circle in the primary sodium pool. Note that with thermal expansion the circle shrinks to 17.6 m diameter.

DETECTION OF NaK LEAKS:

Any leak in a NaK circuit will result in loss of NaK volume in the NaK loop. Should such a volume drop occur that entire heat transport circuit should be shut down, the molten salt drained to its dump tank and the

NaK drained to its the dump tank.

NaK FLOW PATH:

This configuration balances flows, optimizes heat transfer and minimizes thermal stresses. The standard piping connection arrangement for each NaK circuit starting at the induction pump discharge: 1 X 16 inch 90 degree elbow, 1 X straight, the intermediate heat exchanger lower manifold, the intermediate heat exchange tubes, the intermediate heat exchanger upper manifold, 1 X 16 inch straight pipe, 1 X 16 inch tee, the steam generator upper manifold, the steam generator tubes, the steam generator lower manifold, 1 X 16 X 16 X 16 inch tee, 1 X 16 inch X 16 inch X 4 inch tee down to a NaK dump tank, and a 16 inch X 90 degree elbow connection to the induction pump inlet. There is one small drain/fill valve for each heat exchange loop. This arrangement permits practical and safe identification, isolation, draining, replacement and refilling of any defective heat transport loop component.The pipes must have sufficient positioning play to allow for thermal expansion-contraction and possible earthquake related movement.

MANIFOLD VENTING

Both the upper and lower manifolds of each steam generator have 16 inch diameter pressure relief vents to an overhead vacuum space. Each lower manifold vent needs 2 X 16 inch 90 degree elbows to avoid other overhead pipes. In the event of a sudden steam generator tube faoilure these vents relieve the sudden pressure rise first into the vacuum space and then to the outside via a shared rupture disk.

INDUCTION PUMP DISCHARGE VENT

The induction pump discharge vent connects via a custom fitting to the 16 inch X 16 inch X 16 inch tee at the induction pump discharge.

NaK VOLUME:

The volume of each NaK loop can be estimated by assuming that everywhere along that loop except in the heat exchange manifolds the cross sectional area is approximately the same as the cross sectional area of a 16 inch schedule 40S pipe.

Thus the minimum NaK pipe length equivalents are:

Intermediate heat exchange tubes = 6 m

Intermediate heat exchange riser = 8 m

Intermediate heat exchange connectors = 4 m

NaK-salt heat exchange tubes = 6 m

NaK-HTF heat exchange tubes = 6 m

Inter Heat Exchanger connector tube = 8 m

Intermediate heat exchange riser = 8 m

Induction pump = 10 m

6 Manifolds @ [1.1 m X Pi (0.4 m)^2] = 3.317 m^3 /0.073 m^2 = 45.44 m

Room riser = 11 m

Room connector = 3 m

Hence total equivalent pipe length = 115.44 m

NaK volume = 115.44 m X 0.073 m^2 = 8.427 m^3

Required minimum NaK dump tank volume = 9 m^3

DETECTION OF NaK LEAKS:

Any leak in a NaK circuit will result in loss of NaK volume in the NaK loop. Should such a volume drop occur that entire heat transport circuit should be shut down and the NaK drained to its dump tank.

NaK FIRES:

Other parties using NaK for heat transport have experienced repeated fires. The problem is that if hot high NaK is inside a pipe the NaK tends to leak out via any mechanical joint that is less than perfect. The NaK operating temperature is too high for use of conventional elastomeric gaskets. Once outside the pipe the NaK spontaneously ignites in air. That situation is unacceptable.

The solution to this problem is to operate the NaK at less than atmospheric pressure and to fit every NaK loop with a dedicated dump tank. At the first hint of a fire, release of the argon pressure over the relevant dump tank causes the NaK in the affected loop to immediately drain down into its dump tank. This procedure will quickly asphyxiate a NaK fire. Any NaK dribble in a heat exchange gallery can be extinguished using a Na2CO3 fire extinguisher.

WATER FOR DECAY HEAT REMOVAL:

There must be enough reliable water available at the steam generators to remove the fission product decay heat by evaporation of that water.

EROSION:

We need to be concerned about long term erosion of the NaK enclosing materials and precipitation caused by impurities Na2O, NaOH, K2O and KOH in the NaK. A relevant reference is corrosion by caustic soda.

We anticipate the need for side arm filters across the induction pumps to continuously remove solid granular material.

The filter changing apparatus will require pressurized argon.

PROVISIONS FOR SYSTEM MAINTENANCE:

To enable heat transport system service the NaK is transferred into its dump tank.

Application of argon pressure over the NaK dump tank and relief of argon pressure from the top of the NaK loop transfers Nak from the dump tanks into the NaK loop. Reversing this procedure allows the NaK to gravity flow back into its dump tanks.

A NaK level sensor should be provided at the top of each NaK loop to indicate when to close the system fill valve. The supply of argon for presurizing the Nak dump tank and the argon sink from the system top can both be from the primary sodium pool enclosure. Similarly when NaK drain down to its dump tank is required the argon in the dump tank can be vented to the primary sodium pool enclosure and after the argon pressure has sufficiently dropped the argon top vent valve can be openned. Note that for safety this argon top vent valve must be vented over the primary liquid sodium pool.

To expel NaK from the intermediate heat exchanger tubes the NaK level is first drained down to the level of the bottom of the return pipe to the intermediate heat exchanger. Then a blanking disk is installed between the flanges of the intermediate heat exchange bundle NaK discharge pipe. Then argon pressure is applied to the intermediate heat exchange discharge which will drive most of the contained NaK from the intermediate heat exchange bundle into the dump tank.

In reality, even after this procedure is complete a small amount of NaK will remain in the bottom manifold of the intermediate heat exchange bundle and the bottom manifold of the NaK-salt heat exchanger. This small NaK accumulation presents a potential risk to maintenance personnel and a potential fire risk if at some later time oxygen is admitted into the NaK piping. This risk can be minimized by use of a small tube that connects onto the bottom of the intermediate heat exchange bundle lower manifold and removes the remanent NaK by vacuum suction. In general for safety the flange connections of the intermediate heat exchange bundle and the radial piping should be closed with blanking plates while the intermediate heat exchange bundle is still in the argon atmosphere over the primary sodium pool.

PROTECTION OF THE NaK LOOP FROM HIGH TRANSIENT PRESSURES:

In the event of a steam generator tube failure there will be a violent chemical reaction between the NaK and water/steam. This chemical reaction will cause a rapid transient rise in the NaK loop pressure which if not properly managed could cause a liquid NaK pressure pulse analogous to water hammer, potentially rupturing the intermediate heat exchange bundle and possibly leading to major facility damage. Hence the NaK loop must be designed to safely withstand large transient surge pressures and the NaK should normally operate at a pressure of less than 0.1 MPa. Sustained high pressure is prevented by venting the NaK loop to the atmosphere and by dropping the liquid NaK into its dump tank at the first hint of trouble.

On a rise in NaK level the induction pump is stopped, theinjectin pump is stopped and the steam generator shell drain valve is opened. When the steam generator shell side pressure falls below the NaK pressure the NaK pressure the NaK is drained to its dump tank.

In order for the safety mechanisms to reliably function there must also be a mechanism that can provide instantaneous NaK pressure relief. That rate is limited by the maximum NaK flow through the steam geneator tube failure which rate is a function of the heat exchange tube inside diameter and the vent diameter.

In a practical accident scenario the chemical reaction forms hydrogen which rapidly raises the NaK pressure. The hydrogen is vented via a 16 inch OD pressure relief vent.

Each NaK heat transport loop is normally at less than 0.1 MPa absolute. The NaK dump tank also acts as an expansion tank that partially attenuates any pressure pulse in the NaK.

DESIGN CONSTRAINTS:

1) With the steam generators vented to the atmosphere there must be enough NaK natural circulation to dependably remove fission product decay heat so that the system remains safe on loss of electric power to the NaK induction pumps.

2) The inner concrete structural wall protects workers in the heat exchange galleries from gamma radiation emitted by spontaneous decay of Na-24 into Mg-24.

These same walls provide structural support for the gantry crane, the heat exchange gallery equipment and the dome roof.

CALCULATE NaK VISCOUS PRESSURE DROP AT SUFFICIENT NATURAL CIRCULATION TO REMOVE FISSION PRODUCT DECAY HEAT:

An important issue with the intermediate heat exchange bundles is their ability to remove fission product decay heat by natural circulation. In natural circulation the NaK flow rate is low and laminar, so the heat transfer characteristics are different from when the NaK loop is pumped. It is necessary to have a sufficient number of intermediate heat exchange tubes to allow the required natural circulation and laminar flow limited heat transfer. The viscosity of the NaK must be taken into account.