| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|

REFERENCES:

Toronto Star January 14, 2024

Interview with Ben Mulroney January 2024

Processing of Used Nuclear Fuel

Introduction: Recycling of Nuclear Waste (A short summary by Peter Ottensmeyer)

TRU

TRU is an acronym for TRans Uranium actinides, which are elements with atomic numbers greater than 92 that form when the abundant uranium isotope U-238 is exposed to a flux of thermal neutrons.

OTTENSMEYER PLAN:

The Ottensmeyer Plan is an integrated plan for sustainable and dependable supply of clean (non-fossil) power for large scale displacement of fossil fuels. Key components of the Ottensmeyer Plan are:

a) Use of sodium cooled breeding Fast Neutron Reactors (FNRs) with metallic fuel;

b) Use of pyroprocessing, as implemented at the Idaho National Laboratory (INL), for both the initial and periodic fuel reprocessing required by FNRs;

c) Use of recrystallization of uranium nitrate hexahydrate [UO2(NO3)2.6H2O] to concentrate the TRU in used CANDU reactor fuel to economically make feedstock for making FNR start fuel;

The Ottensmeyer Plan is named after its lead proponent, Prof. Peter Ottensmeyer. The Ottensmeyer Plan technology can also be used to eliminate TRU from nuclear fuel waste, reducing the required nuclear waste isolated storage time from more than 400,000 years down to about 300 years and reducing the isolated stored waste volume by about 100 fold.

MAIN FEATURES OF THE OTTENSMEYER PLAN:

The main features of the Ottensmeyer Plan are:

1) A five fold to ten fold cost reduction as compared to pyroprocessing, achieved via a physical rather than a chemical TRU concentration process.

2) Maximum possible harvesting of energy from natural uranium. The Ottensmeyer Plan yields about 100 fold more energy per kg of natural uranium than can be realized with the best thermal (heavy water cooled) reactors and about 1.5 times more energy than can be harvested by used fuel concentration that relies on PUREX plutonium separation chemistry.

3) Minimum possible long lived nuclear waste. A major problem with the nuclear waste recycling methods used by nuclear weapon states such as USA, UK, France, and Russia is that those methods use short fuel cycles and PUREX chemistry to extract Pu, which constitues about half of the TRU. In the nuclear weapon states the other half of the TRU forms long lived nuclear fuel waste. In the Ottensmeyer plan almost all the TRU elements remain as a group and are 100% fissioned.

4) In the Ottensmeyer Plan, due to longer fuel cycles, 0.50 of the TRU is Pu-239 and 0.16 of the TRU is Pu-240. The Pu-240 TRU component, by spontaneous fission, prevents the Pu-239 TRU component from being suitable for making fission bombs. That protection occurs because, due to close atomic weight similarity, it is prohibitively difficult to separate Pu-240 from Pu-239.

5) The Ottensmeyer Plan obtains its TRU from power reactors where the time between successive fuel changes is sufficient to ensure that the Pu-240 fraction in the TRU makes that TRU is useless for military purposes.

6) By fissioning 100% of the TRU the Ottensmeyer plan disposes of all the long lived high atomic weight isotopes. The remaining nuclear fuel waste consists of lower atomic weight fission products, most of which have half lives of less than 30 years.

7) In the Ottensmeyer Plan during successive fuel cycles the fuel atoms are repeatedly electrochemically extracted from a molten chloride salt bath. To the extent that Cl-35 atoms adhere to fuel atoms, those chlorine atoms will become neutron irradiated. If the molten salt bath contains natural chlorine (Cl-35 + Cl-37), then there may be a small tendency for radioactive Cl-36 to accumulate in the molten salt. However, Cl-36 has a 300,000 year half life so the intensity of its radiation emissions is small. This issue will disappear if the Cl in the molten salt bath is pure Cl-37.

IMPLEMENTATION OF THE OTTENSMEYER PLAN:

The motive and detailed implementation of the Ottensmeyer Plan are set out on the following web pages:

TRU Story

and

Ottensmeyer Plan Implementation

and

Ottensmeyer Plan Detail

and

TRU Concentration

and

Uranyl Nitrate Hexahydrate Crystal Growth

and

INZEM Energy

DEVELOPMENT HISTORY:

The Ottensmeyer Plan defines a unique sustainable nuclear fuel cycle that harvests the maximum possible energy from natural uranium while almost eliminating any requirement for long term geologic storage of solid nuclear fuel waste. The underlying strategy in the Ottensmeyer Plan was identifed by Peter Ottensmeyer and his students circa 2010. The critical separation factors were later demonstrated by experimental work in Japan circa 2017 - 2018. ________The cascade required for separating uranyl nitrate hexahydrate from everything else was designed by Charles Rhodes in 2021 - 2023.

This work builds upon enhanced pyroprocessing developed at the Idaho National Laboratory during the period 1995 to 2018, as reported by Yoon Chang._______

The key to the Ottensmeyer Plan is initial TRU concentration by selective extraction of uranium oxide from old used CANDU fuel. This selective extraction need not be perfect in terms of TRU rejection by UO2 because after reduction the extracted uranium is later repeatedly recycled through Fast Neutron Reactors (FNRs) as blanket fuel.

As compared to CANDU reactors, the Ottensmeyer Plan increases the nuclear energy yield per kg of natural uranium by about 100 fold while simultaneously almost eliminating production of long lived solid nuclear waste.

Simple conservation of energy relationships show that world wide sustainable displacement of fossil fuels requires widespread adoption of the Ottensmeyer Plan.

The Ottensmeyer Plan uses multiple successive fuel passes through liquid sodium cooled Fast Neutron Reactors (FNRs) to both breed new TRU in the blanket fuel and to fission the older TRU contained in the core fuel.

Periodically the core and blanket fuels are reprocessed to reject fission products and to move newly bred TRU atoms from the FNR blanket to the FNR core and to replace the missing atoms in the FNR blanket with depleted uranium atoms obtained by reducing uranium oxide that was stored earlier during the TRU concentration process.

The stored uranium component exhibits variable amounts of U-232 decay (72 year half life) primarily due to neutron activation of trace Th-232 impurity. This uranium oxide should be interim stored in stainless steel containers within a depleted high silica hard rock mine that is both naturally dry and continuously accessible.

The Ottensmeyer Plan has a relatively small requirement for isolated multi-century storage of fission products embedded in an initially non-radioactive Li, K and Na dry chloride salt mixture. This salt mixture should be stored in robust porcelain pots with water tight drip shedding lids. These pots should be placed within a depleted high silica hard rock mine that is both naturally dry and is continuously accessible. The dominant longer life radio toxins in fission products are Cs-137 and Sr-90, both of which have half lives of about 30 years. After about 300 years in storage valuable elements can be safely selectively extracted from the fission products.

The Ottensmeyer Plan reduces by more than 1000 fold the present requirement for long term used CANDU fuel storage.

Two diagrams showing material flows within the Ottensmeyer Plan are:

FACILITY BLOCK DIAGRAM

and

RECYCLING BY PYROPROCESSING

The TRU concentration cascade is described at: TRU CONCENTRATION.

After selective uranium oxide extraction the used CANDU fuel residue is subject to reduction and then enhanced pyroprocessing. Enhanced pyroprocessing is an improved version of pyroprocessing developed at the Argonne National Laboratory (now the Idaho National Laboratory) (INL) and described by Yoon Chang in the text Plentiful Energy. An introduction to pyroprocessing is contained in the Pyroprocessing Brochure

In addition to solving the thorny political problem of used CANDU nuclear reactor fuel disposal the Ottensmeyer Plan increases by about 100 fold the amount of energy that can be realized from the finite world supply of mineable natural uranium. This issue is critical for enabling sustainable displacement of fossil fuels by nuclear power.

THE U-232 ISSUE:

An important aspect of the Ottensmeyer Plan is that it is immediately applicable to recycling of used CANDU fuel. Used CANDU fuel contains a U-232 concentration about two orders of magnitude less than the U-232 concentration in used Light Water Reactor (LWR) fuel. This feature is important because U-232 has a hard gamma emission in its alpha decay sequence which triggers a requirement for biosafety shielding at every stage of transport and reprocessing of used LWR fuel.

If used LWR fuel is used to feed a CANDU reactor that reactor must be fitted with appropriate new fuel safety shielding.

Both CANDU reactors and LWRs obtain natural uranium from the same sources. Natural uranium ore is initially chemically purified to remove most of the thorium. However, a trace concentration of thorium remains. In a fission reactor this trace concentration of Th-232 converts to U-232 roughly in proportion to the cumulative neutron flux to which it is exposed.

Uranium which is used for LWR fuel is enriched by discarding a fraction of the heavier isotope U-238 from natural uranium. Since Th-232 has a lower atomic weight than U-238 the enrichment process inadvertently increases the trace Th-232 concentration in the enriched uranium fuel by about an order of magnitude. Then in a LWR, due to the increased U-235 concentration, the cumulative neutron flux per kg of uranium is about an order of magnitude higher than in a CANDU reactor. The net result is that the U-232 concentration in used LWR fuel is about two orders of magnitude higher than the U-232 concentration in used CANDU fuel that is initially natural uranium.

This difference in U-232 concentration between used LWR fuel and used CANDU fuel makes transport of uranium extracted from used LWR fuel much more expensive than transport of uranium extracted from natural uranium sourced used CANDU fuel that has been concentrated on the CANDU reactor site. Hence used CANDU fuel is less expensive to recycle into Fast Neutron Reactor (FNR) fuel than is used LWR fuel.

Generally a better way of using used LWR fuel is to first convert it into CANDU fuel. However, a problem in doing this is that the resulting new CANDU fuel made from used LWR fuel contains more U-232 than new CANDU fuel made from natural uranium. This issue triggers additional new fuel handling safety issues at existing CANDU reactors.

This same U-232 issue comes into play in recycling of used FNR fuel. By the time that a FNR fuel bundle is due to be recycled the cumulative neutron flux seen by the uranium component of the used FNR fuel makes the contained trace U-232 concentration too large for economic on-FNR-site fuel concentration. Hence, complete used FNR fuel bundles should be transported in shielded containers from the FNR site to the FNR fuel recycling site. Fortunately, there is a negligible marginal cost premium for shielded transport of FNR fuel bundles away from the FNR site because the same truck and the same shielded container that are required for delivery of the replacement FNR fuel bundle to the FNR site can be used.

ALTERNATIVE APPROACHES TO CANDU FUEL REPROCESSING:

In order to appreciate the inherent simplicity of the Ottensmeyer Plan it is helpful to briefly look at other potential methods of used CANDU fuel reprocessing.

An early conceptual version of CANDU fuel reprocessing is outlined in: Reprocessing CANDU Spent Fuel. The detailed chemistry is set out in Nitrogen Trifluoride-Based Fluoride-Volatility Separations.

In his textbook Darryl Siemer writes:

It would be more reasonable to first bake-out and then fluorinate such spent fuel (CANDU or LWR) to volatilize the uranium (Markvart 1999 & Rozon & Lister 2008). Baking in air or oxygen (voloxidation) converts dense, brittle, UO2 ceramic fuel pellets to a friable U3O8 powder with which gaseous fluorinating agents can readily react [1]. There are two ways to do the fluorination. The first is to burn the oxides with fluorine gas (the strongest fluorinating agent) which would convert the uranium, neptunium, several fission products and (usually) some of the plutonium to a mixture of gaseous forms which may require further separations. The second is to sequentially affect the separation of gaseous UF6 from NpF6 and the volatile fission product fluorides but leave the plutonium in the ash with a weak fluorinating agent (NF3) in a series of fluidized bed reactors operated at successively higher temperatures (McNamara 2011). Plutonium could then be recovered by either dissolving it to utilize a PUREX-like separation or via exhaustive fluorination with fluorine gas (McNamara 2011). In the case of spent LWR fuels, because the bulk of the recovered uranium would contain more U-235 than would natural uranium, it then should be re-enriched and thereby roughly double the amount of startup fissile recovered.

1. Voloxidation also volatilizes/separates several otherwise troublesome fission products.

Another useful reference textbook is: Radiochemistry and Nuclear Chemistry.

THE OTTENSMEYER PLAN:

A diagramatic overview of the Ottensmeyer Plan is

RECYCLING BY PYROPROCESSING

A detail of the block labelled TRU Concentrator is available at TRU CONCENTRATOR

When the Used CANDU Fuel is exhausted UO2 from the storage is used to make more FNR blanket fuel to replace blanket fuel rod mass that is converted into core rod mass.

A simplified overview of the Ottensmeyer Plan is contained on the following INL PRESENTATION SLIDE SET

A plan safety summary is contained at:

SFR Safety Assesment

The cascade for used CANDU fuel TRU concentration is described at:

TRU CONCENTRATION.

Further information regarding the Ottensmeyer Plan is available at:

a) SUSTAINABLE NUCLEAR POWER.

c) OTTENSMEYER PLAN IMPLEMENTATION

CONCISE FNR DESCRIPTION:

A liquid sodium cooled Fast Neutron Reactor (FNR) consists of a horizontal pancake shaped layer of vertical reactor core fuel rods that is sandwitched between two thicker layers of vertical blanket fuel rods. The fuel rod sandwitch is centrally located in a liquid sodium pool. Fission reactions take place in the core fuel rods. The fertile U-238 blanket rods capture excess neutrons from the fission reaction and transmute U-238 into fissile Pu-239. Periodic reprocessing of the fuel rods extracts fission products from the core fuel rods and transfers new TRU from the blanket fuel rods to the core fuel rods. This process will run as long as there is a supply of replacement fertile U-238 blanket rod material. FNRs also produce spare TRU which can be used to later start Th-232 fueled Molten Salt Reactors (MSRs). FNRs can also fission high atomic weight MSR waste. With appropriate FNR and MSR deployment the known world wide U-238 and Th-232 resources should be sufficient to meet total human energy requirements for several thousand years.

Note that FNR blanket fuel rods should be reprocessed separately from FNR core fuel rods to minimize U-232 accumulation in the FNR blanket fuel. The U-232 concentration in core fuel will plateau due to fast neutron fissioning of U-232. About half of the required FNR blanket fuel reprocessing can be accomplished by simple mechanical blanket fuel rod sorting based on an electronic scan of each blanket rod.

A FNR operates by fissioning the TRU (trans uranium actinides), which are high atomic weight isotopes with long half lives, into low atomic weight fission product isotopes that have relatively short half lives. The fission products, which typically constitute up to about 15% of the FNR used core rod fuel mass, are electrochemically extracted from the used core rod material. The remaining core rod fuel mass along with 15% new core rod mass obtained by reprocessing blanket fuel rods and/or from fissionable nuclear waste from other reactor types, is recycled through a FNR. The removed blanket rod mass is replaced with the abundant fertile isotope U-238.

Continuous repetition of this fuel recycling methodology reduces the natural uranium consumption and used fuel storage requirements per kWh generated by about 100 fold as compared to a CANDU reactor and enables nuclear fuel supply extension by provision of fissile start and reactivity maintenance fuel for Molten Salt Reactors (MSRs). Any small remaining stream of long lived solid radio isotopes is stored in engineered porcelain-stainless steel containers.

The separated fission products are initially kept in isolated interim dry storage for about 300 years during which period their radio toxicity naturally decays below the radio toxicity level of natural uranium. After 300 year interim storage the remaining contained elements with long lived radio isotopes, such as selenium (Se) and tin (Sn), are selectively chemically extracted. After a further 300 years in isolated storage the remaining fission products are released to the environment for reuse. This selective extraction reduces the spent fuel mass requiring long term storage by a further 10 fold. The selectively extracted elements such as Se and Sn that have long lived radio isotopes are sent to long term (~ 1 million year) geologic storage.

The location and structure of the storage is chosen so that the storage will remain naturally dry, will naturally drain, naturally ventilate and will remain safely accessible far into the future. Generally the storage should be in a high elevation depleted mine formed in stable high silica granite in order to be sufficiently robust to withstand repeated glaciations.

The combined 100 X 10 = 1000 fold reduction in spent fuel mass requiring long term storage enables economic use of engineered containers to hold the small spent fuel fraction that actually requires long term storage. This arrangement, which allows periodic inspection of the stored waste containers and future maintenance or replacement of the containers, ensures future ground water purity and provides public safety certainty for thousands of future generations.

The FNRs used for implementation of the Ottensmeyer Plan are designed to minimize production of long lived radio toxic low atomic weight istopes such as Be-10, C-14, Cl-36, Ca-41, Ni-59, Se-79 and Sn-126. These long lived low atomic weight isotopes, if they form, should be extracted from the waste stream and kept isolated from the environment for periods ranging from 60 thousand to 3 million years. To minimize or avoid production of long lived low atomic weight isotopes the FNR fuel assembly should be fabricated out of high purity materials containing minimal amounts of the elements beryllium, carbon, chlorine, calcium, nickel, selenium and tin. Isolation of long lived radio isotopes from the environment for 1 million years requires the use of engineered porcelain encased stainless steel containers with dielectric container wall separation stored in a permanently accessible, naturally ventilated and naturally dry (gravity drained) deep geologic repository formed in stable granite high above the surrounding water table. From a geologic perspective the best such storage site in Canada is Iron Mountain in British Columbia which contains the depleted Jersey Emerald mine that in WWII was the main allied nation source of zinc and tungsten.

As a result of the exclusion of problem elements from fuel tube alloys, especially carbon and nickel, the FNR fuel tubes have constraints on: maximum operating temperature, maximum internal pressure and maximum thermal stress.

In order to prevent leakage neutrons from the reactor blanket impinging on: surrounding intermediate heat exchange tubes, stainless steel pool liner and fire brick insulating walls there is a thick guard band of blanket fuel and liquid sodium between the reactor core fuel and the nearest heat exchange tube or sodium pool containment wall. The guard band thickness requirement sets a minimum on the sodium pool size which makes it impractical to fully assemble the sodium pool in a factory. Instead FNRs should be site assembled from factory built and tested modules, each of which can be readily transported to the FNR site by road and/or rail.

A key element of the Ottensmeyer Plan is concentration of used CANDU reactor fuel on CANDU reactor sites. This concentration process involves use of an automated uranium oxide recrystalization cascade to extract nearly pure uranium oxide from used CANDU fuel. Important secondary functions of this apparatus are:

a) Extraction and capture of the inert gases Ar, Kr and Xe;

b) Extraction and capture of Cs;

c) Extraction and capture of Zr;

d) Extraction of Np along with the U. The U with some Np goes into storage for future use as FNR blanket fuel material.

This automated cascade reduces the used fuel transportation costs by about 8 fold.

The extent of the fuel concentration by this method is limited to about 10:1 by potential thermal neutron criticality in the concentrate solution.

TECHNICAL REFERENCES:

The Ottensmeyer Plan, as conceived by Peter Ottensmeyer, is described in the following documents:

| LINK NAME | DOCUMENT TITLE |

|---|---|

| Ottensmeyer CNS Annual 2023 | TWO UNAVOIDABLE ESSENTIAL REQUIREMENTS FOR A CANADIAN LONGTERM WASTE-FREE NUCLEAR FUTURE: RECYCLING OF USED FUEL AND FAST-SPECTRUM FISSILE-BREEDER SMRs |

| G4SR-4 | Your New SMR Must Not Be Thermal |

| CANDU Fuel Conference | Used CANDU Fuel: Energy Independence and $1 Billion Carbon-Free Electricity Per Tonne |

| Neutrons at the Core (2021) | US Amazon link |

| Neutrons at the Core (2021) | Canadian Amazon link |

| Ottensmeyer-CNS2021 | The Right Kind of SMR for Today and Tomorrow |

| Ottensmeyer 19-09-08 | THE SMR CHALLENGE IN CANADA: ENRICHED FUEL; A SOLUTION: RECYCLING OF USED CANDU FUEL |

| Ottensmeyer 18-06-03 | Benefits of Fast Neutrons: CANDU Fuel Creation, Waste Elimination And Clean Power |

| Ottensmeyer 16-09 | Used CANDU Fuel Reassessed: A Reactor's Fuel Waste - A Long Term Treasure Trove For Ontario |

| Ottensmeyer 16-09 | The Travesty of Discarding Used CANDU Fuel |

| Ottensmeyer 15-05-31 | Productive Elimination of Nuclear Waste (PENW): A Complementary Boon for CANDUs and the Canadian Nuclear Industry |

| Ottensmeyer 14-05-25 | Synergy Between CANDU and Fast-Neutron Reactor Technologies |

| Ottensmeyer 13-05-21 | Nuclear Fuel Waste Consumed and Eliminated: Environmentally Responsible, Economically Sound, Energetically Enormous |

| Ottensmeyer 13-03-18 | Accelerated Reduction of Used CANDU Fuel Waste with Fast-Neutron Reactors: Fuel Cycle Strategy Cuts TRU Waste Lifetime from 400,000 Years to Less than 80 Years |

| Ottensmeyer 12-07-xx | ENGINEERING DIMENSIONS - CANDU FUEL WASTE RE-USED, RECYCLED, ELIMINATED: $45 TRILLION OF CARBON-FREE ELECTRICITY VIA FAST-NEUTRON REACTORS |

| Ottensmeyer 12-06-10 | Used CANDU Fuel Waste Consumed and Eliminated: Environmentally Responsible, Economically Sound, Energetically Enormous |

| Pyroprocessing Slides | Pyroprocessing System |

The practical realization of the required fast neutron spectrum with a liquid sodium cooled fast neutron reactor is the subject of two books. The book titled: Plentiful Energy - The Story of the Integral Fast Reactor by Charles E. Till and Yoon Il Chang provides a good introduction to the subject. The book titled EBR-II Experimental Breeder Reactor-II by Leonard J. Koch provides more in depth technical detail.

A commercial fast neutron reactor known as the GEH PRISM, which is a design evolution of the EBR-2, has been promoted by GE-Hitchi. Technical details about this reactor are available at: GEH PRISM.

Many aspects of the theory and practical realization of FNRs are set out at www.xylenepower.com web site. On almost any web page click on Nuclear Power from the menu at the top or bottom of the web page and then scroll down to the long list of files at the bottom of the Nuclear Power web page.

EFFECT OF GOVERNMENTAL INCOMPETENCE/CORRUPTION:

In April 2016 the Canadian Nuclear Laboratories (CNL) released a report titled A Feasibility Study on the Recycling of Used CANDU Fuel.

CNL Research and Development Report # 153-124900-REPT-002 Revision 0. Unfortunately the authors of this report relied on blatently false information provided to them by the Nuclear Waste Management Organization (NWMO). The NWMO has been subject to high level government corruption, driven by fossile fuel interests.

The information provided by the NWMO to CNL in 2016 indicates that the cost of a DGR for 3.6 million CANDU Used Nuclear Fuel bundles is $19,360 million. In 2013 parties in the Canadian mining industry offered the NWMO, OPG and the Ontario Ministry of Energy an existing fully formed 5,000,000 ft^2 Deep Geologic Repository (DGR) complete with both mineral and surface rights to 50 km^2 of surroundinng property for $67.5 million. Even if the cost of upgrading this existing DGR to include improved natural drainage, improved natural ventilation, new utility services and engineered spent fuel storage containers was as much as $900 million there would still be a price discrepency of about 20:1. This price discrepency can only be explained by very deep seated incompetence/corruption within both the Canadian federal government department controlling the NWMO and the Ontario Ministry of Energy controlling Ontario Power Generation (OPG). The failure of both the NWMO and OPG to purchase the existing DGR when it was available at a bargain price will likely go down in history as one of the worst ever decisions by the Canadian and Ontario governments. Today key parts of the existing DGR facility have been purchased by Chinese investors.

In addition to incorrect conclusions contained in the CNL report flowing from the incorrect DGR cost there are also major technical problems, some of which are highlighted in a document titled Critique of Feasability Study on Recycling by Peter Ottensmeyer.

BENEFITS OF THE OTTENSMEYER PLAN:

As compared to the CANDU fuel cycle the Ottensmeyer Plan reduces the required long term spent nuclear fuel Deep Geologic Repository (DGR) mass storage capacity by about 1000 fold per kWh of energy output and increases the energy yield per unit of natural uranium consumed by over 100 fold by transmuting otherwise unused U-238 and Th-232 into TRU and then fissioning the TRU.

The Ottensmeyer Plan also provides major material cost saving via recycling of expensive materials. Under the Ottensmeyer Plan recycling of the existing spent nuclear fuel inventory would reduce natural uranium requirements per kWh of energy output by about 100 fold. In addition to providing much more energy per unit of mined natural uranium the Ottensmeyer Plan also potentially makes very low concentration uranium ore bodies economic. This issue will become increasingly important in the future as nuclear power displaces fossil fuels.

The Ottensmeyer Plan is highly proliferation resistant. During implementation of the Ottensmeyer Plan U-238 is gradually transformed into a TRU mixture which is then fissioned to produce energy. With the contemplated first-in first-out fuel cycle the ratio of Pu-240 / Pu-239 in the TRU is sufficiently high to prevent chemically extracted plutonium from being suitable for weapons production. The effect of addition of Pu-240 to the Pu-239 in a plutonium type atom bomb is to cause premature ignition so that the bomb blows itself apart before most of the Pu-239 can react. To produce a practical atom bomb from a Pu-239 / Pu-240 mixture the Pu-240 must be separated from the Pu-239. That isotope separation process is much more difficult than separating U-235 from U-238 and hence is considered essentially impossible.

OTTENSMEYER PLAN IMPACT:

The Ottensmeyer Plan will fundamentally change the direction of the nuclear power industry. The Ottensmeyer plan is financially enabled by recognition that the two major cost components of nuclear energy are long term supply of natural uranium and long term disposaol of nuclear fuel waste. The true cost of nuclear fuel is not just the cost of finding and mining new uranium and chemically purifying it. The true cost includes the cost of safely disposing of used nuclear reactor fuel and other neutron activated nuclear waste. When nuclear electricity generators are forced to pay the full cost of nuclear waste disposal the nuclear reactor technologies employed will change to favor technologies that minimize production of low atomic weight long half life radio isotopes and that transmute high atomic weight long half life isotopes into low atomic weight short half life isotopes.

One of the blunt realities that electric power utilities must ultimately face is phase out of water moderated power reactors in order to achieve the much higher uranium utilization efficiency and used fuel disposal benefits provided by the Ottensmeyer Plan. The liquid sodium cooled FNRs used to implement the Ottensmeyer Plan could also provide the start fuel required by future thorium fueled molten salt reactors (MSRs).

HISTORY:

During the early 1960s personnel at Atomic Energy of Canada Ltd. (AECL) measured interaction properties between elements and fast neutrons. An important finding was that generally for the trans uranium actinides the fast neutron fission cross section is larger than the fast neutron capture cross section. Hence exposure of a material containing trans uranium actinides to a fast neutron flux causes a gradual decrease in the trans uranium actinide concentration.

An important related issue is that when a fast neutron emitted by a fission reaction impacts a U-238 atom there may be a n > 2 n reaction that increases the number of free neutrons present.

During the period 1964 to 1994 a highly successful 20 MWe liquid sodium cooled fast neutron reactor technology was developed and demonstrated at the Argonne Labs in Idaho, USA (now the Idaho National Lab) with a reactor known as EBR-2 (Experimental Breeder Reactor #2). In 1994 the EBR-2 program was defunded by US president Bill Clinton. That defunding decision set back the US nuclear energy program by at least 30 years as compared to other major industrialized countries such as Russia, China, India, UK, France, Japan and South Korea. In the context of limiting fossil fuel driven climate change that defunding decision was one of the worst ever decisions by a US president.

FAST NEUTRON PHYSICS:

Fast neutrons have the property that when they interact with the transuranic actinides (atoms heavier than uranium) they preferentially trigger fission reactions instead of alpha or beta decays. Each Pu-239 fission reaction releases about 3.1 fast neutrons that can sustain a fast neutron process. A fission reaction typically causes about a 50% change in atomic number as compared to a less than 2% change in atomic number for an alpha or beta decay. Hence the resulting low atomic weight fission product atoms can be physically separated from high atomic weight transuranic actinide atoms by an electrochemical separation process that sorts atoms by atomic weight.

In an advanced Fast Neutron Reactor (FNR) the reactivity is controlled by relative positioning of fuel bundles such that at the desired liquid sodium discharge temperature thermal expansion of the fuel assembly reduces the reactor reactivity to zero.

DEVELOPMENT OF THE OTTENSMEYER PLAN:

In the years 2010 to 2012 a retired university professor named Peter Ottensmeyer used AECL measured neutron interaction parameters to conclude that spent CANDU fuel should be placed in accessible dry storage, sorted, reprocessed and recycled rather than being buried in an inaccessible deep geologic location as contemplated by the Nuclear Waste Management Organization (NWMO). Ottensmeyer's conclusions and the related nuclear waste recycling process are collectively known as the Ottensmeyer Plan. Professor Peter Ottensmeyer, in an article published in the Ontario Professional Engineers publication ENGINEERING DIMENSIONS, pointed out that the toxic lifetime of CANDU spent fuel bundles can be reduced more than 1,000 fold by repeated exposure of the recycled spent CANDU fuel to a fast neutron spectrum together with repeated extraction of fission products.

The extracted fission products must be kept in interim isolated dry storage for about 300 years while the radio toxicity of the short lived fission products naturally decays below the level of natural uranium. After 300 years in storage selective chemical extraction of remaining radio active elements can be used to further reduce the mass that must be kept in longer term storage. The interim fission product storage requires a safe, accessible and secure naturally ventilated dry storage facility and engineered containers with dependable multi-century working lives.

The technical viability of the Ottensmeyer Plan was quickly confirmed by others with relevant scientific and engineering knowledge. During the period 2013-2021 implementation details of the Ottensmeyer Plan were further refined.

OTTENSMEYER'S OBSERVATIONS:

The Ottensmeyer Plan is based on a number of straight forward scientific observations made by Peter Ottensmeyer. These observations are summarized below.

OTTENSMEYER'S 1ST OBSERVATION:

Ottensmeyer's first observation was that nuclear waste is radio active because it contains unextracted potential energy. If all of the available potential energy is extracted the nuclear waste will no longer be radio active. Hence, one of the objectives of the Ottensmeyer Plan is to harvest all of the available potential energy contained in nuclear fuel.

OTTENSMEYER'S 2ND OBSERVATION:

Ottensmeyer's 2nd observation was that spent CANDU fuel contains over 97% uranium oxide (UO2). Pure uranium oxide is only very weakly radioactive. Uranium oxide has chemical and physical properties that allow it along with Np to be selectively extracted from the spent CANDU fuel using recrystalization with a separation ratio per step of as much as 100. Thus, in a few cascade steps about ~ 90% of the mass of the used CANDU fuel in the form of UO2 can be safely extracted amd placed in interim storage pending future use.. The remaining ~ 10% of the used CANDU fuel mass can then be economically processed via more sophisticated means. This initial fuel concentration also concentrates the transuranium actinides (TRU) which increases the rate at which the TRU are fissioned in a fast neutron reactor. This initial process step also extracts radioactive inert gases and Cs, which extraction makes practical subsequent molten salt electrolytic used fuel residue component separation.

OTTEMSMEYER'S 3RD OBSERVATION:

Ottensmeyer's 3rd observation was that the radio toxicity of the remaining spent CANDU fuel bundles primarily consists of two components, the transuranic actinides (TRU) which decay via sequential alpha particle and beta particle emission and fission products which decay via only beta particle emission. He noted that the TRU atoms take about 400,000 years to spontaneously decay to the radio toxicity of natural uranium whereas the fission products decay to the radio toxicity of natural uranium in less than 300 years. Ottensmeyer's depicition of the relative radiotoxicity decay rates is shown in the diagram below.

On this graph it is important to note that the ordinate axis is relative radio toxicity, not relative energy emission. To obtain relative energy emission the fission product data values must be increased by a factor of 20 because the fission products are beta emitters whereas the actinides are alpha emitters. On a per unit of energy basis the beta emitters are about 20 fold less radio toxic than the alpha emitters.

At ten years after CANDU fuel bundle removal from a CANDU reactor the fission product decay heat is about 20X the TRU decay heat but the radio toxicity of the fission products is similar to the radio toxicity of the TRU.

Note that the quantity of contained fission products and TRU is not the same in all spent CANDU fuel bundles. The decay heat thermal output calculated from this Ottesnsmeyer graph, relative to the decay heat from natural uranium, at 1 year, 10 years and 100 years after removal from the reactor, varies from 26% to 66% of the thermal output values indicated by the NWMO. The likely explanation for this data discrepency is that the NWMO and Ottensmeyer used different assumptions as to the various isotope concentrations at the instant of spent fuel bundle removal from the CANDU reactor.

OTTEMSMEYER'S 4TH OBSERVATION:

Ottensmeyer's 4th observation was that an essential aspect of fast neutron reactor fuel treatment is to completely convert the TRU into fission products, because the fission products have much shorter half lives.

OTTENSMEYER'S 5TH OBSERVATION:

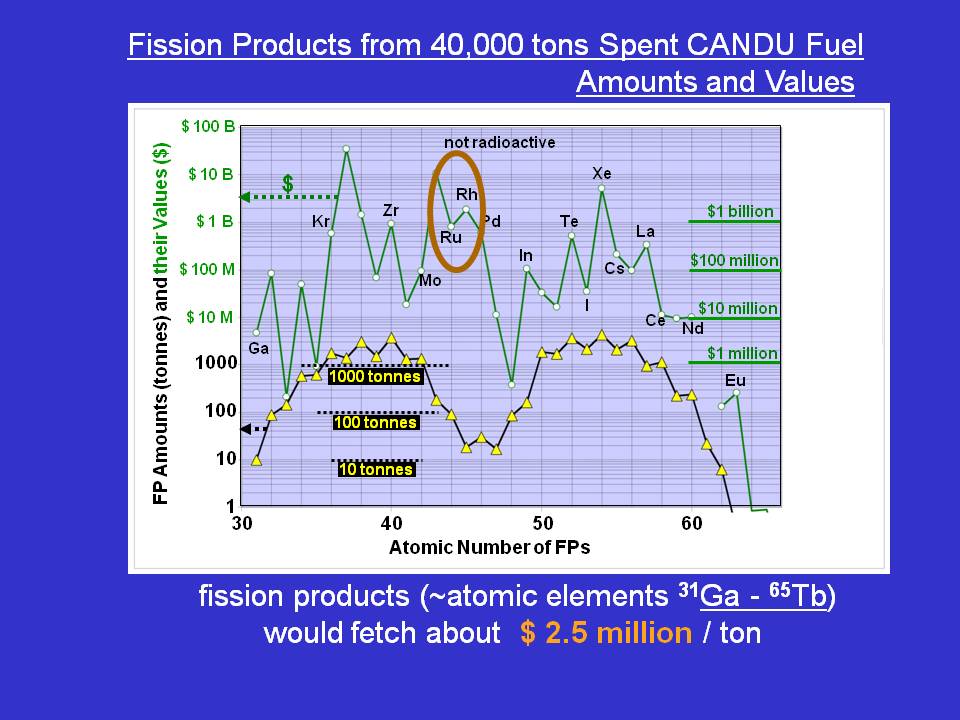

Ottensmeyer's 5th observation was that the TRU fission products are mainly rare earth atoms that in the case of Pt and Ir have a high economic value. Currently there are about 60,000 tonnes of used CANDU fuel. If this used fuel is fully converted into TRU fission products and then stored for 300 years to reduce its radio toxicity the amounts of the various fission products and their current values are shown on Ottensmeyer's graph below. The potential financial value of this material is impressive.

OTTENSMEYER'S 6TH OBSERVATION:

Ottensmeyer's 6th observation was that in a fast neutron nuclear reactor only about 15% of the core rod fuel mass is consumed before the combination of decline in Pu-239 concentration, accumulation of high neutron cross section fission products and fuel tube swelling force removal and reprocessing of the fuel rods. Hence, to fully consume the TRU, it is necessary to selectively extract the low atomic weight fission products from the high atomic weight TRU and then to recycle the high atomic weight TRU through the reactor. This fission product extraction and fuel recycling process must be repeated many times at multi-year intervals.

In this respect Ottensmeyer and his engineering students investigated mechanical-chemical processes that would allow achievement of high separation ratios between uranium oxide (UO2), TRU and fission products. Inportant later work was done by others to quantify and automate the separation process, as described at TRU Concentration .

OTTENSMEYER'S 7TH OBSERVATION:

Ottensmeyer's 7th observation was that a practical way of separating fission products from TRU is to sort the atoms based on their atomic weight. Most fission product atoms have an atomic weight less than cadmium (atomic weight = 112.41). Hence to a first order fission product atoms will float in liquid cadmium whereas the actinides will sink. More precise atomic weight selection can be achieved by taking advantage of different atomic electrochemical properties.

OTTENSMEYER"S 8th OBSERVATION:

Ottensmeyer's 8th observation was that the concentration of U-232 in used CANDU fuel made from natural uranium is much less than the concentration of U-232 in used Light Water Reactor (LWR) fuel made by enriching natural uranium. Hence if pure uranium is selectively extracted from used CANDU fuel the radioactivity of that pure uranium is relatively very low.

RESULT:

Drawing on his observations Peter Ottensmeyer developed the initial version of the Ottensmeyer Plan for processing used CANDU fuel bundles. Some implementation aspects of the Ottensmeyer Plan, particularly the uranium oxide extraction cascade, have since been refined by Charles Rhodes.

A document that addresses practical aspects of used nuclear fuel reprocessing is:Processing of Used Nuclear Fuel

ENHANCED OTTENSMEYER PLAN:

This web site focuses on large scale implementation of the Ottensmeyer Plan in Canada. In other jurisdictions with different reactor types and different geography the implementation detail may be different. The key steps of the Enhanced Ottensmeyer Plan are:

a) Selective extraction of uranium oxide from used CANDU fuel on CANDU reactor sites to form pure uranium oxide and used CANDU fuel TRU concentrate. This process also extracts Zr, Ar, Kr, Xe, Cs and Np from the used CANDU fuel;

b) Economic transport of both used CANDU fuel TRU concentrate and nearly pure uranium oxide to the reprocessing site;

c) Reduction of metal oxides to metals;

d) Separation of the used CANDU fuel metallic concentrate into Zr, fission products, U and TRU;

e) Three hundred year dry accessible storage of the remaining fission products;

f) Forming Fast Neutron Reactor (FNR) core fuel from the TRU, U, and Zr;

g) Forming FNR blanket fuel from the U and Zr;

h) Using FNRs to convert fertile U-238 in the FNR blanket into TRU;

i) Extraction of fission products from used FNR core fuel;

j) Moving new TRU material from blanket fuel rods to core fuel rods;

k) Replacing lost blanket fuel fertile material mass with an equal mass of new fertile U-238;

The approximate design of 1000 MWt (300 MWe) fast neutron reactor suitable for implementation of the Ottensmeyer Plan is developed at FNR DESIGN. Issues related to reactor fuel tube selection are set out at FNR FUEL TUBES and at FNR FUEL TUBE WEAR. The details of the fuel reprocessing are set out at FNR MATERIAL RECYCLING and at OTTENSMEYER PLAN DETAIL.

RHODES 1st OBSERVATION:

Charles Rhodes examined practical issues with respect to implementation of the Ottensmeyer Plan. He concluded that due to the shipping weight of the required biosafety shielding it is economically impractical to transport fully assembled spent CANDU fuel bundles off a CANDU reactor site as contemplated by the NWMO. To reduce the transportation cost it is essential to first selectively extract 90% of the spent CANDU fuel bundle weight and volume in the form of low radioactivity uranium oxide. Hence the first step of the Ottensmeyer Plan, selective uranium oxide extraction, should be implemented at each CANDU reactor site.

RHODES 2nd OBSERVATION:

Rhodes observed that in practical implementation of the Ottensmeyer Plan over 90% of the fuel mass to be reprocessed is potentially FNR blanket rod material, not FNR core rod material. By making the blanket rods from depleted uranium selectively extracted from used CANDU fuel the blanket rod processing can be simplified and the cost greatly reduced. Since the blanket rods constitute much of the total FNR fuel weight, the resulting cost savings are substantial.

RHODES 3rd OBSERVATION:

Rhodes concluded that after 90% of the uranium oxide is selectively extracted from the used CANDU reactor fuel the remaining used fuel residue can be economically shipped by truck and/or rail to Chalk River in reusable lead containers. The more complex steps of fuel oxide reduction, sophisticated electrolytic/density separation by atomic weight and then subsequent fuel rod fabrication can be implemented at a shared facility at Chalk River.

To mitigate potential transportation accidents involving possible immersion in water during shipment the water moderated reactor fuel concentrates and FNR core fuel should be stabilized with gadolinium. The extracted fission products can be shipped from Chalk River to the 300 year interim storage site by truck and/or rail, again in reusable lead containers.

Then much of the net shipping weight is nearly pure uranium oxide that can be safely shipped in conventional containers at minimum cost.

RHODES 4th OBSERVATION:

Rhodes observed that in practical implementation of the Ottensmeyer Plan zirconium, which constitutes about 10% of fast neutron reactor fuel rod mass, can be extracted both during uranium extraction and during TRU concentrate separation. This radioactive zirconium, after separation, should be recycled back into the FNR fuel.

RHODES 5th OBSERVATION:

Rhodes observed that at INL, where the molten salt electrolytic separation process is used, it is extremely important from a practical perspective, to extract Cs, Ar and Kr in an earlier process to that they do not become hazards during the high temperature electrolytic process. Early complete Cs extraction is extremely important.

RHODES 6th OBSERVATION:

Rhodes observed that the plenum space in the fuel tubes must be sufficient to accommodate both spare liquid sodium and inert gas fission products. Due to the high energy neutrons causing fuel tube crystal structure changes the fuel tube material tends to swell, increasing the volume inside the fuel tube. There must be enough spare sodium to ensure that through out the working life of the fuel tube the gap between the fuel rods and the fuel tube is entirely filled with liquid sodium. During the fuel tube working life the fuel tube material gradually converts from iron to chromium and then to titanium. The yield stress of the fuel tube material may decrease with time. Hence the fuel tube plenum size must be sufficiently large to ensure that the combined fuel tube pressure stress from inert gas fission products and thermal stress due to the heat flux in the core zone at full reactor power remains safely below the fuel tube material yield stress.

RHODES 7th OBSERVATION:

Rhodes observed that the mass of liquid sodium inside the fuel tube must be more than sufficient to chemically absorb the corrosive fission products including F, Cl, I and Br.

RHODES 8th OBSERVATION:

Rhodes observed that the fuel tubes should be arranged in a square grid rather than a staggered grid to ensure continued good circulation of liquid sodium coolant in the presence of moderate fuel tube swelling. This issue introduces a potential complication due to the change in ratio between the fissile atoms and coolant sodium atoms and the effect of this ratio on the change in reactivity with increasing temperature.

RHODES 9th OBSERVATION:

Rhodes observed that after the fission products have been in storage for 300 years there will still be significant concentrations of the long lived low atomic weight isotopes Se-79 and Sn-126. Selenium (Se) and tin (Sn) should be selectively extracted from the decayed fission products before the fission products are released into the environment.

RHODES 10th OBSERVATION:

Rhodes observed that the activation and fission products include the radio active inert gases Ar-39 (half life = 269 years) and Kr-81 (half life = 210,000 years). There is no practical method of reliably containing these inert gases for anything like 10 half lives. If mankind relies on fission nuclear energy over many years the Ar-39 and Kr-81 concentrations in the atmosphere will gradually increase. There is no practical alternative other than for all life forms on Earth to gradually adapt to the corresponding increase in the background radiation. Provided that there is reasonable atmospheric dispersal the increase in the background radiation should be acceptable.

RHODES 11th OBSERVATION:

There is a shorter lived inert gas fission product radio isotope Kr-85 which may eventually be a concern, not because of its long half life but rather because of its shorter half life of 10.76 years. Again, if mankind relies on large scale nuclear power it will be necessary to adapt to a higher atmospheric concentration of Kr-85. In the past there was some concern expressed in the literature about the possible atmospheric consequences of Kr-85. See "Meteorological Consequences of Atmospheric Krypton-85" by William L. Boeck, Science 16 July 1976, Volume 193, Number 4249.

OTTENSMEYER PLAN SUMMARY:

According to the NWMO (Choosing A Way Forward 2005, Appendix 3) fresh CANDU fuel consists of 99.28% U-238 and 0.72% U-235 and used CANDU fuel consists of 98.58% U-238, 0.23% U-235, 0.07% U-236, 0.25% Pu-239, 0.10% Pu-240, 0.02% Pu-241, 0.01% Pu-242 and 0.74% fission products. Note that these numbers do not include the weight fraction of the zirconium cladding tubes, which is close to 10%. Note that these numberss actually vary a bit due to reactor non-uniformity and due to long term changes in reactor fuel bundle design.

Prior to TRU concentration the fraction of the non-zirconium used fuel that is plutonium oxide is:

0.25% + 0.10% + 0.02% + 0.01% = 0.38%.

Prior to TRU concentration the fraction of the non-zirconium used fuel weight that is uranium oxide is:

98.58% + 0.23% + 0.07% = 98.88%.

In order to realize core fuel for a FNR which consists of 70% uranium, 10% zirconium and 20% TRU it is necessary to retain:

(70 / 20) X 0.38% = 1.33%

of the original used CANDU fuel weight before TRU concentration as uranium oxide.

Thus the weight of (uranium + plutonium) in the core rod material is:

1.33% + .38% = 1.71% of the original used CANDU fuel weight before TRU concentration.

Thus the weight of (uranium + plutonium + fission products) in the core rod material prior to fission product extraction by pyroprocessing and prior to TRU concentration is:

1.71% + .74% = 2.45%

of the original used CANDU fuel weight

The significance of these issues is that during initial FNR fuel fabrication only the water moderated reactor fuel TRU concentrates need to be reduced from oxide form to metallic form. The remaining nearly pure uranium oxide can be stored to be used for future FNR blanket mass replacement.

The weight of (uranium + plutonium + zirconium) in the core rods is:

(10 / 9) X 1.71% of used CANDU fuel weight

= 1.90% of used CANDU fuel weight.

Hence the maximum weight of initial core rod material that can be realized from 60,000 tonnes of used CANDU fuel including zirconium is:

.0190 X 60,000 tonnes = 1140 tonnes

The corresponding amount of zirconium involved is:

0.1 X 1140 tonnes = 114 tonnes.

During the initial core rod material fabrication the amount of fission products that must be extracted via pyroprocessing is:

.0074 X 60,000 tonnes = 444 tonnes

Note that during one fuel cycle the neutron absorption by the blanket rods should be sufficient to produce about twice the amount of plutonium consumed by the reactor core during that same fuel cycle.

Note that the fuel rods contain 10% zirconium. This zirconium is rejected by the pyroprocess. This zirconium can then recovered by the dry chloride zirconium recovery process and used to form about 10% of the weight of the new fuel rods.

FUEL PROCESSING:

The fuel processing steps required in the Ottensmeyer Plan are set out on the web pages titled:

FNR MATERIAL RECYCLING

and OTTENSMEYER PLAN DETAIL

A proposal for handling of the residual mixture of LiCl, KCl and fission products is contained in a paper by Darryl Siemer titled:

Improving the Integral Fast Reactor Salt Waste Management System

An alternative salt cleanup methodology has been advanced by Yoon Chang and is depicted on the following diagram:

____________________________________________________

REACTOR OPERATION:

During each fuel cycle a FNR converts about 15% of its core rod fuel weight into fission products. These fission products are extracted by pyroprocessing and are placed in containers for 300 year dry storage. While it is theoretically possible to operate an FNR so that it converts a higher fraction of its core fuel to fission products during each fuel cycle the economics are questionable due to reduced fuel bundle thermal power and increased required fuel tube plenum volume.

During each fuel cycle the liquid sodium within the fuel tubes chemically captures the corrosive fission products fluorine, chlorine, iodine and bromine. Hence the liquid sodium in the fuel tubes, in additon to providing good thermal contact between the fuel rods and the steel tubes, performs the esential function of chemical absorption of these potentially corrosive fission product gases. Absent the sodium these gases would increase the internal pressure in the fuel tubes and would corrode the steel fuel tube material. During subsequent fuel reprocessing these sodium salts should be selectively extracted and sent to long term storage because they will contain the long lived isotopes Cl-36 and I-129.

The high atomic weight material left behind after fission product and zirconium extraction via pyroprocessing is a mixture of uranium and TRU. The extracted weight of fission products is replaced by an equal weight of new core rod material. The material wihin the blanket rod process is replenished by depleted uranium obtained from the inventory of nearly pure uranium oxide fuel inventory. Note that this inventory contains small fractions of U-235 and TRU which will both fission in the neutron flux in the FNR blanket.

In the FNR core the mass ratio of U-238 to TRU is initially (70 / 20). The U-238 fast neutron capture cross section is 0.25 b. The Pu-239 fast neutron fission cross section is 1.7 b. Hence in the core region for every Pu-239 fission there is breeding of about:

(70 / 20)(0.25 b) / (1.7 b) = 0.514

replacement TRU atoms. These replacement TRU atoms together with TRU atoms bred in the adjacent blanket regions extend the operating life of the fuel.

IRRADIATED MATERIAL HANDLING:

The core and blanket FNR fuel rods are removed from the FNR and are separately processed. The neutron irradiated blanket rods are an input to the blanket rod process. The residue from the blanket rod process is rich in TRU and zirconium and is used as an input to the core rod process. The neutron irradiated core rods are a further input to the core rod process.

The FNR blanket rods cannot form a critical mass and hence can be safely processed with minimum transportation, storage and handling costs.

The core rod material, if mishandled, could potentially form a dangerous critical mass. Hence, for public safety the core rod reprocessing should be conducted at a remote facility such as Chalk River that is far from any urban center. Fuel bundles containing core fuel rods are transported in gadolinium lined containers to prevent a critical mass forming if water penetrates the shipping container.

The FNR operation and reprocessing cycle is repeated over and over for both blanket rod material and core rod material until all of the available high atomic weight atoms contained in the available spent CANDU fuel are consumed.

Implementation of the Ottensmeyer Plan yields sufficient TRU from the existing CANDU spent fuel inventory to start about a dozen 1000 MWt power FNRs.

Implementation of the Ottensmeyer Plan increases the fraction of CANDU fuel that fissions from less than 1% to almost 100%.

While in interim 300 year storage the fission products naturally decay to become stable elements with potential high economic value. The fission product stream contains a few low atomic weight elements with isotopes that have long half lives. These isotopes should be selectively extracted after 300 years in storage. A good reference is:

Radioactive waste partitioning and transmutation within advanced fuel cycles.

The selectively extracted long lived radioactive isotopes should be placed in very long term DGR storage.

Prior to FNR fuel reprocessing the fuel tube assembly should be disassembled using automated equipment and physically separated into steel, sodium, sodium compounds, blanket rods and core rods. Sodium and sodium compounds adhering to the fuel tube material can be stripped off with water. This physical separation greatly simplifies subsequent fuel reprocessing steps.

OTTENSMEYER PLAN IMPLEMENTATION:

The Ottensmeyer Plan uses technologies that have proven performance in: selective uranium oxide extraction, separation of low and high atomic weight elements, selective extraction of zirconium, long term preservation and water exclusion.

In the Ottensmeyer Plan water exclusion problems are avoided by storing the radioactive material in engineered containers that are kept within a permanently accessible naturally dry (gravity drained) and naturally ventilated Deep Geologic Repository (DGR). This DGR should be at least 300 m above the local water table and should be kept at atmospheric pressure and temperature by natural ventilation. Resistance to DGR damage by glaciation and other events is ensured by forming the DGR inside the stable high density high silica granite core of a mountain that provides over 400 m of overhead rock above the DGR. There is no attempt to find a "receptive community" for this DGR because at any geologically suitable DGR site there is insufficient fresh water to support a permanent community. In the Ottensmeyer Plan the DGR location is determined by favorable geophysical criteria, not by political criteria.

In the Ottensmeyer Plan double wall storage containers (outer wall porcelain, and inner wall stainless steel, oil dielectric in between the outer and inner walls) are used for long term storage of the radioactive material while it is in the DGR. While in the DGR the physical integrity of each nuclear waste storage container is remotely monitored by monitoring the container's dielectric level. During the initial storage period the dielectric will out gas and may need occasional replacement.

OTTENSMEYER PLAN FEATURES AND BENEFITS:

The main features and benefits of the Ottensmeyer Plan are:

1) It provides certain safe disposal of nuclear fuel waste, including: used light water reactor fuel and used heavy water (CANDU) reactor fuel;

2) The average required storage time for nuclear fuel waste is reduced by about 1000 fold from 400,000 years to about 400 years;

3) The useful energy yield per unit of natural uranium consumed is increased by over 100 fold as compared to a CANDU reactor;

4) The stored nuclear fuel waste is reliably isolated from ground water;

5) If an accessible DGR and suitable nuclear waste containers are also used for interim storage then the interim storage can safely default to becoming a long term storage facility if future changes in human society so dictate;

6) It is not necessary to build large nuclear waste storage facilities that can only be used once and then must remain in isolation for over 400,000 years. Most of the storage space can be recycled at three century intervals;

7) The interim depleted uranium storage containers need only be engineered to last a few hundred years;

8) The Ottensmeyer Plan for radio isotope storage can be implemented using suitable existing high altitude naturally dry depleted hard rock mine facilities in granite mountain cores;

9) Both the DGR storage space and the double wall porcelain-stainless steel containers can potentially be reused;

10) The integrity status of each nuclear waste container is remotely monitored for safety and security;

11) The Ottensmeyer Plan is relatively simple and inexpensive to implement as compared to the present NWMO / OPG nuclear waste disposal plan.

12) The nuclear industry material costs are greatly reduced under the Ottensmeyer Plan due to recycling of almost all of the neutron activated material. The dry accessible interim storage methodology of the Ottensmeyer Plan allows recovery and reuse of over irradiated zirconium and helium-3 that are contained in the current inventory of low and intermediate level nuclear waste.

13) Over 60,000 tonnes of existing used CANDU nuclear fuel are converted via fission into valuble elements with atomic numbers in the range 31 to 65. Note that recovery of elements with atomic numbers in the range 49 to 65 may require a second stage of pyro processing for atomic weight separation.

14) The problem of used nuclear fuel management and disposal is not passed on to numerous future generations. The high level waste stream is almost entirely eliminated. The costs of nuclear waste disposal are largely met by the persons who benefit from the nuclear energy generated.

15) The technology for implementing the Ottensmeyer Plan has been demonstrated. This technology uses a proven liquid sodium fast neutron reactor coolant and a proven fuel design based on metallic uranium-TRU-zirconium alloy core rods, metallic uranium-zirconium alloy blanket rods and sodium contained within HT-9 steel fuel tubes.

16) It is contemplated that the new fast neutron reactors would use cooling towers instead of the direct lake water cooling presently used by CANDU reactors. Use of cooling towers allows siting reactors at higher elevations above major water bodies, which reduces risks due to earth quakes, tsunamis and other geophysical events outside human control. The higher primary coolant temperature of a liquid sodium cooled fast neutron reactor as compared to a water moderated reactor increases the electrical generation efficiency. The low primary coolant pressure in a FNR contributes to facility safety. Unlike a CANDU reactor there is no potential source of radioactive steam. The major plant design issue is isolation of liquid sodium from both air and water. The use of cooling towers greatly reduces the impact of reactor cooling on marine life.

17) The use of liquid sodium cooled FNRs allows rapid reactor power changes which allow the reactor power to track rapid changes in electricity grid load.

REDUNDANT SAFETY MEASURES:

No solid or liquid exits to the environment from the Ottensmeyer Plan process until its radio toxicity is below the radio toxicity of natural uranium. However, at any instant in time there may be substantial inventories of unprocessed and partially processed radio isotopes. Hence a high, dry and accessible facility is required for interim radio isotope storage. All of the dangerous radio isotopes in this storage are kept in double-walled individually monitored containers. Any container wall failure is detected via a liquid dielectric level change long before there is any radioactive material leakage.

The radio isotope containers are stored in an accessible naturally dry gravity drained depleted hard rock mines with sumps such that if there is a radio isotope leakage it is detected at a sump and remedial measures can be implemented long before there is any leak of radio isotopes into the external environment. Since the UO2 only requires a few hundred years for interim storage, the containers used for UO2 containment do not have to reliably function for more than a few centuries. To put that time in perspective, Egyptian mummies contained in naturally dry limestone pyrmid storage have lasted 5000 years.

CHOICE OF DGR:

The Ottensmeyer Plan impacts immediate decisions relating to the storage of low and intermediate nuclear waste because it replaces long term storage of nuclear waste in an expensive inaccessible low and wet DGR with relatively short interim storage of most of the nuclear waste in a relatively inexpensive and accessible high and dry DGR.

There is a requirement for safe, secure and accessible isolated dry storage site(s) for the entire inventory of uranium oxide contained in the spent CANDU fuel bundle material which is about 95% of the CANDU spent fuel mass. Jersey Emerald, in British Columbia, is particularly suitable for both interim and long term radio isotope storage and may be available at a modest price. Other depleted mine sites may be suitable but are unlikely to be as geologically advantageous.

ECONOMIC IMPLEMENTATION:

The main issue preventing immediate implementation of the Ottensmeyer Plan is that the present cost of natural uranium to CANDU nuclear reactor owners is so low and the financial amounts required to be set aside for future nuclear waste disposal are so low that recycling spent CANDU fuel does not make financial sense for present CANDU reactor owners. Used CANDU fuel bundles, after being removed from a CANDU reactor used fuel cooling bay, are simply placed in on-site concrete-steel dry storage casks. However, the working life of these casks was only initially intended to be 50 years. The total amount of this dry storage is becoming very large from a future safety, security, operating and maintenance cost perspective.

In order for the nuclear waste issue to be taken seriously by CANDU reactor owners the financial amounts required to be set aside for nuclear waste disposal must be increased at least ten fold so as to be sufficient to finance the DGRs contemplated by the Nuclear Waste Management Organization (NWMO). At that point the Ottensmeyer Plan will be a financially viable alternative that is preferred by knowledgable nuclear industry intervenors.

GOVERNMENTAL FAILURE:

Outside of North America numerous parties have recognized that the future of mankind will rely on nuclear energy. In Russia power FNRs have already been developed and have operated for over 30 years. The US, Canadian and Ontario governments have been seized by the fossil fuel industry. The result is that Canada and the USA have moved from being a world leaders in FNR matters in the mid 1960s to being banana republics now half a century later. The governments of the US, Canada and Ontario are in a state of nuclear power decision paralysis. These governments have almost zero competence with respect to both nuclear matters and reducing emissions of fossil fuel products of combustion.

The Ottensmeyer Plan for handling nuclear waste requires that politicians face the reality that nuclear power is essential to provide dependable non-fossil power. These politicians must then face NIMBYism relating to safe transport, safe storage and safe reprocessing of nuclear fuel. These same politicians must also set electricity rates that encourage efficient use of the electricity system and must expropriate energy transmission corridors that are sufficient to allow total displacement of fossil fuels by non-fossil (clean) energy.

NON-PROLIFERATION:

The major issue with Pu-239 is that to prevent atomic weapon proliferation it should never be produced without accompanying Pu-240 so that there is no available inventory of separated Pu-239. Implementation of the Ottensmeyer Plan needs to be 100% transparent and fully open to both Canadian Nuclear Safety Commission and International Atomic Energy Agency inspection to ensure that Pu-239 is never produced without diluting Pu-240 and so that the plutonium contained in the spent CANDU fuel and used FNR fuel is never chemically isolated.

All routes into or out of isolated high level nuclear waste processing and storage facilities, such as Chalk River and Jersey Emerald, should be monitored with helium-3 based neutron detectors to ensure that there is no illicit transport of fissionable material.

FUEL MANAGEMENT:

There are two situations, reprocessing of used CANDU fuel and reprocessing of used FNR fuel.

Used CANDU Fuel Management

Used CANDU fuel bundles can be extracted from dry storage canisters on the CANDU reactor site and processed on that site to extract 90% of the U using a recrystallization process cascade. This process will run almost continuously. The remaining 10% is highly radioactive and is trucked to the reprocessing facility in lead containers. These containers must be protected against accidental immersion in water. The pure uranium, which is of low radioactivity, can simply be shipped in barrels.

At the reprocessing facility the fission products (chloride salts) are extracted and placed in porcelain containers that have water proof drip shedding tops but will vent gases. The porcelain containers fit inside a lead shipping container which in turn fits in either an 18 wheel truck or a railway car. The shipping vehicle goes directly to Jersey-Emerald where the lead container is removed and placed on a dolly. Inside Jersey-Emerald a truck mounted robot drives the dolly into a storage room, removes the porcelain container from the lead container and places the porcelain container on a pre-prepared rimmed concrete pad or shelf. The rim limits the container's motion during an earthquake.

Jersey-Emerald is naturally ventilated so toxic gas and heat accumulation are not issues. Periodically a robot goes into Jersey-Emerald to check that all the porcelain containers are sealed and OK. After the fission products have naturally decayed the porcelain containers are removed and their contents recycled. The average residence time inside Jersey Emerald can be greatly reduced if there is a chemical process for selective extraction of. Sr and Cs. Absent such selective chemistry the minimum storage time is 300 years.

FNR Fuel Bundle Management:

I am concerned with FNRs that are located in urban areas to allow economic district heating. Each FNR has in-sodium space, outside the neutron flux, for storage of used fuel bundles for six years. Every six years the reactor is shut down, and the used fuel bundles are removed, suitably packed for shipping safety and trucked directly to the reprocessing facility. At the reprocessing facility the fission products are removed and sent to Jersey Emerald as described above. The remainder is electrolytically reprocessed to make FNR fuel. The FNR fuel is assembled into fuel bundles.The fuel bundles are packed with a gadolinium or like compound that will prevent them going critical if they are accidentally immersed in water.

Each FNR fuel bundle is shipped in an individual lead container. These containers lie horizontally on a flat deck truck. Everything is dimensioned such that the ful bundles slide from the truck mounted container into the FNR airlock and vice versa. Inside the sodim pool space the overhead gantry crane flips the fuel bundle to its vertical position and moves it to its desired position in the fuel assembly.

Every six years fuel bundles are removed from the storage section, flipped to the horizontal position and sent for reprocessing. Used fuel bundles are moved to the storage section. Remaining fuel bundles are shuffled. Then new fuel bundles are inserted.

Jersey Emerald

I particularly like Jersey Emerald because it is probably the most secure available fortress in North America. Most natural caves are in limestone and are the result of long term action of water. Jersey Emerald was cut by men out of the core of a volcano that never erupted. The igneous rock is so dense that it cannot be cut by a tunnel boring machine. It can only be cut by drill and blast. It is naturally dry because it is about 1 km above the local water table. It contains stored rain water at a tremendous head pressure. It is huge because it was the main source of tungsten and zinc for the allies in WWII. It is exceptionally stable. No need for shoring except at tunnel entrances. There are many miles of existing truck tunnels. The purchase price of the facility is millions, not billions of dollars. The main political issue is providing employment.for local indians. The mine closed more than 50 years ago. Today it is uneconomic from a mining perspective.

Jersey-Emerald arose as a result of the unique naval demands of WWII. It was an effort comparable to the Manhattan Project. Replacing Jersey Emerald today might easily cost over $50 billion. The secret town of Jersey-Emerald no longer exists, but during WWII it was comparable to Los Alamos. To fail to take advantage of this unique facility is just plain stupid. Come what may with climate change, the igneous hard rock Jersey Emerald workings will still be there long after the limestone pyramids of Egypt are gone.

This web page last updated December 1, 2024.

| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|