| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|

This web page is concerned with detail related to the steam generator design.

NUCLEAR ELECTRICITY:

A nuclear reactor produces heat which is used to heat circulating NaK. The steam generator uses that heat to produce high pressure (10 MPa) steam for driving a steam turbine. The high pressure steam expands through a turbine which in turn drives a line synchronous generator to produce 60 Hz 3 Phase electric power. Ideally the steam generator acts as a constant temperature constant pressure variable mass flow steam source. The system power is changed by changing the NaK mass flow. A water level sensor controls the flow of high pressure inlet water.

A steam generator reference paper is Steam Generation - An Overview by Babcock and Wilcox.

Spray evaporator theory is discussed in the reference: Spray Evaporator Theory

Steam plants are discussed in the references: Steam Plant Operation and Industrial Boilers and Heat Recovery Steam Generators.

The possible use of a supercritical CO2 system for converting heat to electricity is discussed in:

Improving SFR Economics Through Innovation

STEAM GENERATOR OVERVIEW

A FNR steam generator is in essence a vertical tube in shell heat exchanger with low pressure induction pump circulated NaK flowing downward through tubes while high pressure expanding water/steam moves upward on the shell side. The steam generator provides isolation between the NaK and the water.

If a tube fails it tends to collapse, minimizing the contact area between NaK and water. Further, generally such sudden failures are limited to a single tube in 1081 tubes and the NaK-water contact area is limited to twice the single tube bore area.

The steam generator features a shell and tubes with matched temperature coefficients of expansion and a shell heater designed to minimize the axial tube stress caused by differential temperatures between the tube material and the shell material.

The steam generator maximum OD including insulation so as not to conflict with Heat Exchange Gallery end walls is given by:

Pi (42 m) / 56 = 2.356 m

= 2.356 m / (0.0254 m / inch)

= 92.76 inch

This consists of 72 inch OD shell flanges and 10 inches of insulation over the flanges. The 12 inch wide manifold flanges would be consistent with a 24 inch diameter pipe, implying that the manifold pressure must be reduced by a factor of four with respect to the shell pressure. Since the shell working presure is 10 MPa, from the perspective of the manifold flanges the maximum manifold pressure is 2.5 MPa. That is OK since we are capping the manifold pressure at 1.7 MPa due to the pressure limit in the induction pump flow tubes.

Note that to provide service access alternate steam generators are radially staggered. The steam generators adjacent to the air locks used for intermediate heat exchanger insertion or removal must be located as close as possible to the outer cylindrical structual wall to allow thickening of the adjacent shear wall near the inner cylindrical structural wall.

Each steam generator has two end manifolds, each rated for the maximum NaK working pressure (1.7 MPa). The manifold flanges are nominally 72 inches OD at the flange and 92 inches OD when insulated. The manifold covers are removeable for interior access and inspection and are held in place by numerous bolts. NaK pipe connections are made to the manifold sides. The manifold flange gaskets are nickel plated copper._______

The steam discharge port from each steam generator is 8 inch OD and is fitted with a pressure relief safety vent. There is a pressure regulating valve close to the turbogenerator. The safety vents are fabricated from schedule 80 pipe_____. The steam discharge from the isolation valves feeds a shared steam main going toward the turbogenerator. The protruing flange faces are located 32 inches (0.8 m) from the steam generator center line so that the 36 inch radius manifold flanges protect the other machined flange faces from handling damage when the steam generator is on its side on a flat surface.

The injection water inlet to the steam generator shell bottom must be pressure rated for the steam generator working pressure.

The shell heater heats the shell length that is clear of the shell connections. The steam discharge connection flange is 16 inches OD and the adhacent shell to tubes sheet weld requires 6 inches for a total of 22 inches. The inlet water connection flange is 8 inches OD and the adhacent shell to tube sheet weld requires 6 inches for total of 14 inches. This the heating jacket length is:

240 inch - 2 (tube sheet thickness) - 36 inch,

The jacket is fabricated from a length of 60 inch OD, 1 inch wall pipe. The jacket end piesces 60 inch OD, 48 inch ID, 1 inch thick, The jacket connectionflanges must protrude less than 6 inches from the jaclet.

The intermdiate heat exchange bundes are installed to achieve precise NaK pipe alignment with the corresponding steam generators. The steam pipes are potentially more tolerant of alignment error with holes in the floor of the turbogenerator hall. These holes can be large enough to provide mis-alignment tolerance. The low pressure NaK pipes connected to the steam generator permit thermal expansion/contraction and modest earthquake tolerance by radially moving the intermediate heat exchange bundles.

Outside the heat exchange galleries the shared 20 inch diameter steam pipes slope downwards towards the remote turbogenerator. These pipes go under the adjacent roadway.

STEAM GENERATOR DESCRIPTION:

The steam generator consists of three stacked coaxial sections. Starting from the bottom:

1) A bottom manifold cover rated at 1.7 MPa.

2) A 1 m high bottom manifold which discharges the cool (330 deg C) NaK into a 16 inch OD schedule 40S pipe. This section has schedule 40S fittings. Also connected to this manifold is a 16 inch double Tee to a 16 inch schedle 40S OD vent which is configured, as set out below,to safely absorb 1.7 MPa NaK hammer pressure pulses.

3) A 6 m high 10 MPa rated 48 inch OD middle tube section where rising water in the shell is heated by the falling NaK in the tubes. This section has thick wall high pressure rated water bottom inlet and 8 inch OD steam top discharge pipes. This section also has an external variable power thermal jacket to minimize thermal stress related to differential thermal expansion between the tubes and the shell.

4) A 1 m high top manifold which inputs hot NaK from a 16 inch OD schedule 40S inlet pipe and distributes it to the vertical tubes. The horizontal NaK inlet pipe has a 16 inch X 16 inch X 16 inch tee. The rising vertical tee branch connects to a rising 16 inch OD vent which is configured to safely absorb NaK hammer pressure pulses.

5) A top manifold cover rates at 1.7 MPa.

6) The vacuum space high up each rising vent is fitted with another 16 inch X 16 inch X 16 inch tee. The main axis of this tee is vertical and connects to a long 16 inch pipe which is firmly capped at the top. The function of this pipe section is to safely absorb high velocity slugs of liquid NaK. The branch of this tee connects horizontally to a vertical elbow and 16 inch vertical pipe, a ball check and a rupture disk to the outside. The function of this assembly is to safely absorb the NaK hammer pressure pulse that can occur on the sudden failure of a steam generator tube.

7) There is a further rising vent from the induction pump discharge to the vacuum chamber. The main function of this vent is to prevent gas accumulation near the induction pump discharge.

8) On the occurrence of a sudden steam generator tube failure a large steam bubble is formed in the NaK near the steam generator tube failure. The displaced incompressible liquid NaK is forced at a high velocity up the vent(s) into the vacuum space. The following steam bubble exists via the branch in the vertical tee, the vertical elbow, the ball check and the rupture disk. After the steam and hydrogen pressures decay the ball check prevents air entry into the NaK loop.

The tubed section of the steam generator is 6 m tall including the tube sheets. Each end manifold is 1 m tall exclusive of its end cover. A FNR steam generator and its support equipment are designed so that a steam generator tube rupture does not create a dangerous situation due to high pressure super heated water jetting into the NaK circut, flashing to steam, forming hydrogen gas and causing NaK hammer damage to the intermediate heat exchange bundle.

The NaK pressure is normally at less than the surrounding fluid pressure. The NaK pressure head and level is maintained by gravity, an overhead vacuum space and by overhead argon pressure in the NaK dump tanks.

The NaK is hottest in the jacket, flows to the top manifold of the steam generator and then flows almost straight downwards inside the tubes. The water is coolest at the bottom of the steam generator shell space above the lower manifold and flows upwards in a zig zag pattern set by internal flow baffles. The high thermal conductivity of the NaK minimizes heat transfer limitations due to laminar NaK flow in the steam generator tubes.

STEAM GENERATOR CONSTRUCTION

The steam generator consists of a tube and shell heat exchanger with thermal insulation and a heated external jacket to minimize linear tube stress. Hot low pressure NaK flows downward through the tubes. Heat moves through the tube walls and the shell by thermal conduction to vaporize water and heat steam on the shell side.

An important aspect of this steam generator design is that the tube sheets are thick and are externally welded to the shell. This weld may be 6 inches wide. The perimeter portions of the tube sheets where tube sheet flexing can occur are unwelded for about 6 inches in radius beyond the tubes. The issue is that absent the heated thermal jacket the tubes will tend to run hotter than the shell causing the tubes to be in axial compression. The internal steam pressure in the shell acts on the tube sheets in the same direction. The net compresive tube thermal stress is mitigated by use of a heated shell jacket.

Absent the heated jacket the tube temperature approaches the NaK temperture whereas the shell temperature approaches the steam temperature which is consistently lower than the NaK temperature.

The thermal jacket must accommodate the injection water port and the steam discharge port. It must also accommodate two small ports required for internal water level sensing.

STEAM GENERATOR SHELL WALL THICKNESS:

Choose a cylindrical shell with an outside diameter of 48 inches. Barlow's formula gives the maximum working pressure Pm as:

Pm = [2 Sy W] / [3 D]

where:

Sy = yield stress

W = wall thickness

D = inside diameter

or

[3 Pm / 2 Sy] = [W / D]

However for this example:

D + 2 W = 48 inch

or

D = 48 inch - 2 W

or

W / D = W / (48 inch - 2 W)

giving:

[3 Pm / 2 Sy] = W / (48 inch - 2 W)

or

(48 inch - 2 W)[3 Pm / 2 Sy] = W

or

W [1 + 2 (3 Pm / 2 Sy)] = 48 inch (3 Pm / 2 Sy)

or

W = 48 inch (3 Pm / 2 Sy) / [1 + 2 (3 Pm / 2 Sy)]

In the case of the steam generator:

Choose:

Pm = 10 MPa

Sy = 117 MPa

[3 Pm / 2 Sy]

= 30 MPa / 234 MPa

= 0.128

giving:

W = 48 inch (3 Pm / 2 Sy) / [1 + 2 (3 Pm / 2 Sy)]

= 48 inch (30 MPa / 234 MPa) / [1 + (30 MPa / 234 MPa)]

= 48 inch [(0.128) /(1.128)]

= 5.446 inch

Hence the shell wall thickness should be 5.446 inch

Hence the shell inside diameter available for tubes is:

48 inch - 2(5.446 inch) = 37.106 inch

Choose shell wall thickness = 5.5 inch

SHELL CROSS SECTIONAL AREA:

Shell cross sectional area = Pi [(24 inch)^2 - (18.5 inch)^2]

= Pi [576 - 342.25) inch^2

= 734.35 inch^2

TUBE CROSS SECTIONAL AREA:

Tube cross sectional area = 1801 tubes Pi [(0.25 inch)^2 - (0.1875 inch)^2] / tube

= 1801 tubes Pi [.0625 - .0351] inch^2 / tube

= 154.71 inch^2

Hence under axial stress the shell is much stiffer than the tubes.

Hence under axial stress caused by internal steam pressure the tubes are much softer than the shell.

TUBE LINEAR STRESS:

The tube sheet can be modelled in two sections. The middle section is a disk 37 inches in diameter containing 1801 tubes, each 0.5 inch OD.

The axial force on this tube sheet portion caused by the steam pressure is:

10 MPa [Pi (18.5 inch)^2 - Pi (1801)(0.25inch)^2]

= 10 MPa Pi [ 342.25 - 112.56) inch^2

= 10 MPa (721.78 inch^2)x 147 lb /inch^2 MPa

= 1,061,018 lb

The outer section is an annulus with an outside radius of 24 inches and an inside radius of 18.5 inches. The axial force on this tube sheet portion caused by the steam pressure is:

10 MPa Pi [(24 inch)^2 - (18.5 inch)^2)]

= 10 MPa Pi [576 inch^2 - 342.25 inch^2]

= 10 MPa [734.35 inch^2] 147 lb/inch^2 MPa

= 1,079,490.5 lbs

The maximum axial force that the tubes alone can withstand is:

(Tube cross sectional area) X 10,000 lb / inch^2

= 154.71 inch^2 X 10,000lb/ inch^2

= 1,547,100 lb

To the extent that the tube sheet can flex the steam pressure puts the tubes in linear tension. To the extent that the NaK temperature exceeds the water/steam temperature the tubes are placed in linear compression. By use of an electric shell heater the tube linear compression can be reduced. By use of thick tube sheets the tube linear tension can be reduced.

TUBE SHEET THICKNESS:

Note that:

a)Tube sheet is 24 inches larger in diameter than is the shell OD.

b) The tube sheet is externally welded to the shell;

c) The weld radius will extend about 6 inches beyond the shell radius;

d) At radii in the range 0 to 18.5 inch the tubes partially stabilize the tube sheet:

e) At radii in the range 18.5 inch to 24 inch there is no weld;

f) In this radius range the tube sheet slightly flexs to absorb temperature and pressure induced stresses

g) It is important that the end of the shell in this radius range and the tube sheet both be flat.

Absent tubes the tube sheet thickness T required to keep the tube sheet material inits rated stress range is given by:

T = D [3 Pm / 8 Sy]^0.5

= 48 inch [3 (10 MPa) / 8 (117 MPa)]^0.5

= 48 inch [0.0635]

= 8.593 inch

With tube holes the value of Sy decreases with the average tube sheet material density. With no holes the average material density is proportional to:

Pi (18.5 inch)^2.

= Pi (342.25)

With tube holes the average material density is proportional to:

Pi (18.5 inch)^2 - 1801 Pi (0.25 inch)^2

= Pi[342.25 - 112.5625] inch^2

= Pi (229.6825)

Hence for radii less than 18.5 inch the effective value of Sy is:

[Pi (229.6825) / Pi (342.25)] 117 MPa

= 78.518 MPa

When tube holes are present the effective axial pressure on the tube sheet is also reduced by the factor:

[229.6825 / 342.25]

Recall that:

T = D [3 Pm / 8 Sy]^0.5

For radii less than 18.5 inches the term:

[3 Pm / 8 Sy]^0.5

is unchanged. However, for that radius range:

D = 37 inches.

Hence for that radius range it is theoretically possible to reduce the tube sheet thickness T to:

(37 inch / 48 inch) (8.593 inch) = 6.624 inch

However, that thinning of the tube sheet will allow it to flex which will transfer additional steam pressure induced linear tensile stress onto the steam generator tubes. That linear stress can easily exceed the tube tensile (Sy / 3) rating, especially for the central tubes. Hence it appears to be a better strategy to keep the tube sheet rigid and thermally expand the shell length for compressive tube stress relief caused by the NaK temperature being larger than the shell temperature.

The tubes are externally welded to the tube sheets. Typically the tubes extend about (1 / 8) inch beyond the tube sheets at both ends.

SHELL AND TUBE SHEET TEMPERATURES:

Assume outside of shell is well insulated and there is no therma jacket..

Hence shell material inside temperature = inside liquid temperature.

Average tube material temperature = [(NaK temperature - inside fluid temperature) / 2] + [inside fluid temperature]

Due to steam boundary layer the upper tube sheet temperature = hot NaK temperature.

Due to steam boundary layer the tube temperture above and below the liquid level = the NaK temperature which is a function of height.

Due to a layer of internal thermal insulation the bottom tube sheet temperature = bottom NaK temperature.

Near the bottom of the shell wall the shell temperature = bottom internal water temperature.

STEAM GENERATOR SHELL SPECIFICTIONS:

Material = 316L stainless steel

Flange OD = 1.8 m (72 inch)

Shell OD = 1.2 m (48 inch)

Shell wall = 5.5 inch = 0.139 m

Shell ID = 0.635 m (37 inch)

Tube sheet thickness = 8.6 inch =0.218 m

Use 0.0625 inch wall but pressure test to 15 MPa.

In practise real tubes have a minimum wall thickness of 0.0625 inch.

We need to calculate the temperature drop across the tube wall for Inconel 600.

In normal operation the steam generator end manifolds contain liquid NaK at below atmospheric pressure. On a steam generator tube failure the potentially destructive pressure source is the water at 10 MPa gauge, 310 degrees C to 320 deg C.

TRACK ANALYSIS:

Choose:

Circular Track width = 3 /4 inch

Number of potential Semi-Circular Tracks = 37 inch/ (3 / 4)inch = 49.3 tracks

Hence use 49 semicircular tracks

Tube open cross sectional area:

1801 tubes X Pi X [(3 / 16) inch]^2

= 198.91 inch^2

Tube material cross sectional area:

1801 tubes X Pi X [(0.25 inch)^2 - (0.375inch/ 2)^2]

= 1801 tubes X Pi X [.0625 inch^2 - 0.03515 inch^2]

= 154.7465 inch^2

Steam generator cross sectional area occupied by tubes is:

1801 tubes X Pi X (0.25 inch)^2 = 353.625 inch^2

Tube sheet area subject to internal pressure:

Pi X (24 inch)^2 - 353.625 inch

1809.55 - 353.625 = 1455.932 inch^2

Shell cross sectional area:

Pi X [(24 inch)^2 - (37 inch / 2)^2]

= Pi X [576 inch^2 - 342.25 inch^2]

= 734.347 inch^2

For the special case of the shell bearing no linear load the maximum steam pressure induced tensile linear working

stress on the tube material is:

10 MPa X 1455.932 inch^2 / 154.7465 inch^2

= 94.08 MPa

This amount is way over the 39 MPa linear stress maximum for the tubes implying that the shell must must take up most of the internal steam pressure load.

For the special case of the tubes bearing no linear load the maximum pressure induced linear tensile stress seen by the shell is:

10 MPa X 1455.932 inch^2 / 734.347 inch^2 = 19.826 MPa

Clearly the tube sheets must be thick enough to transfer most of the pressure induced linear tensile tube stress onto the shell.

For the special case of a perfectly rigid tube sheet and the tubes and shell both at the same temperature the pressure induced material tensile stress in both the tubes and tube sheet is:

10 MPa X 1455.932 in^2 / [734.347 in^2 + 154.7465 in^2]

= 17.99 MPa

Clearly, even with rigid tube sheets there is not a lot of margin between 17.99 MPa tensile and 39 MPa compressive for the average tube temperature to exceed the average shell temperature. Hence we need a heated jacket to raise the average shell temperature.

WATER/STEAM SIDE SURFACE AREAS:

The water side surface area of the shell is:

= Pi (37 inch)(5.6 m)

= Pi (207.2 inch m)

The water side surface area of the tubes is:

1801 Pi (0.5 inch) (5.6 m)

= 5042.8 inch m

Thus we need about (1 / 25) of the steam generator rated thermal power to keep the shell water side temperature at the same temperature as the tube water side temperature. This is a very expensive solution. Steam generators often use bent or spiral tubes to allow linear compression of the tubes.

One way of mitigating this problem is to use a shell with a slightly greater TCE than the straight tubes. Then bringing the system up to operating temperature with rigid tube sheets puts straight tubes in tension. That tension is relieved as the tubes rise in temperature with respect to the water. This appears to be the simplest solution. It may involve a bit of engineering of the tube sheet thickness and proper shell and tube alloy choices to realize the desired TCE values.

THERMAL STRESS:

The basic thermal stress problem is that absent a jacket heater for the shell, the tubes tend to run hotter than the shell. We can compensate for this problem by directly heating the shell.

For stainless steels the thermal coefficient of expansion is typically:

dL / L = (1.6 X 10^-5 / deg C) dT

Y = Young's modulus = (stress / strain)

or

(stress) = Y [strain]

= Y (dL / L)

= Y (1.5 X 10^-5 / deg C) dT

For stainless steel:

Y = 200 GPa

Hence for tube between fixed endpoints the thermal induced stress is:

(stress) = 200 GPa (1.6 X 10^-5) / deg C X dT

= 200,000 MPa (16 X 10^-6) / deg C X dT

= 3.2 MPa / deg C X dT

Recall that with rigid tube sheets at 10 MPa steampressure the pressure induced tube tensile stress is:

17.99 MPa.

Hence with rigid tube sheets the value of dT that reduces net tube linear stress to zero is:

dT = 17.99 MPa / [3.2 MPa / deg C = 5.62 deg C.

Real values of dT are much larger indicating that without a shell heater the tubes will always be in compressive stress.

The maximum tolerable value of dT without use of a jacket heater is:

(17.99 MPa + 39 MPa) / (3 MPa / deg C) = 19.66 deg C.

However, due to steam boundary layers this temperature difference can easily be doubled. Hence a jacket heater is essential for steam generator tube linear compressive stress relief.

RADIAL THERMAL FLUX:

Radial thermal flux through the wall of an internally heated tube:

P = - K (dT / dR) dA

dA = 2 Pi R dL

P = - K (dT / dR) 2 Pi R dL

or

(dT / dR)= - P / [K 2 Pi R dL]

or

dT = - {P / K 2 Pi dL}{dR / R}

or

Tb - Ta = - {P / K 2 Pi dL} Ln(Rb / Ra)

or

Ta - Tb = {P / K 2 Pi dL} Ln(Rb / Ra)

For the tubes:

Pt = 21 MWt

dL = 5.56 m X 1801 tubes = 10,013 m

Ln (Rb / Ra) = Ln(4 / 3) = 0.28768

Hence for the tubes:

Ta - Tb = {1 / K 2 Pi}{Pt / dL} Ln (4 / 3)

= {1 / K 2 Pi}(21 MWt / 10,013 m}(0.28768)

For 316 stainless steel the thermal conductivity K at 450 deg C is:

21 W / m deg C

Hence for SS tubes:

Ta - Tb = (1 / [21 W / m deg C X 2 Pi])(21 X 10^6 W / 10,013 m)(0.28768)

= 4.57 deg C

without consideration of boundary layers.

If the steam generator tubes are replaced by more expensive Inconel 600 tubes:

Ta - Tb = (1 / [20.9 W / m deg C X 2 Pi])(21 X 10^6 W / 10,013 m)(0.28768)

= 4.594 deg C

without consideration of boundary layers.

For the shell:

Tb - Ta = {Ps / K 2 Pi dL} Ln(Rb / Ra)

Tb - Ta = (1 / K 2 Pi)(Ps / dL) Ln (Rb / Ra)

= (1 / K 2 Pi)(Ps / 5.56 m) Ln (24 / 18.5)

=(1 / K 2 Pi)(Ps / 5.56 m) (0.26028)

Equating the two temperature drops gives:

{1 / K 2 Pi}(21 MWt / 10,013 m}(0.28768) = (1 / K 2 Pi)(Ps / 5.56 m) (0.26028)

or

(21 MWt / 10,013 m}(0.28768) =(Ps / 5.56 m) (0.26028)

or

Ps = 5.56 m / 10,013 m)(21 MWt) (0.28768 / 0.26028)

= (21 MWt / 1801)(1.105)

= 12.88 kW

This jacket heater power must vary in proportion to the system thermal power.

SPECIFICATIONS:

316 SS Density 7980 kg / m^3

326 SS Coeffixient of linear expansion: 16.2 X 10^-6 / deg C

Steam generator upper manifold inside length = 1.0 m

Steam generator lower manifold inside length = 1.0 m

Steam generator tube length = 6.0 m

TUBE SHEET THICKNESS CALCULATION:

Recall that as shown in FNR Heat Transport System the thickness T of a solid end cap is given by:

T = D [3 Pm / 8 Sy]^0.5

= 48 inch [3 (10 MPa) / 8 (117 MPa)]^0.5

= 48 inch [0.0635]

= 8.593 inch

This thickness actually applies to the tube sheets. This thickness is mitigated by linear tension in the tubes.WE MUST CALCULATE THE CAPACITY OF THE TUBES TO MITIGATE THE END FORCE ON THE TUBE SHEETS.

Note that the required tube sheet thickness reduces the surface area available for heat exchange.

Assume outside of shell is well insulated.

Hence shell material temperature = uniform radially at inside fluid temperature.

Due to steam boundary layer the upper tube sheet temperture = hot NaK temperature.

Due to steam boundary layer the tube temperture above and below the liquid level = the internal NaK temperature

Due to a layer of internal thermal insulationthebottom tube sheet temperature = bottom NaK temperature.

Near the bottom of the shell wall the shell temperature = bottom water temperature.

Main shell outside diameter = 48 inchSummary Specifications:

Shell OD = 48 inches

Jacket OD = 52 inch

Overall tube length = 6.0 m

Shell length = 6 m

Flange OD = 72 inches

STEAM GENERATOR TUBE WALL THICKNESS:

The tubes in the steam generator form part of the NaK circuit. Choose the tube ID = 3/8 inch. Then for the stainless steel tubes the minimum wall thickness W is given by:

10 MPa (0.50 inch) = 39 MPa (2 W)

or

W = 10 MPa (0.5 inch) / 39 MPa (2)

= 0.0641 inch

Use 0.0625 inch wall but pressure test to 15 MPa.

In practise real tubes have a minimum wall thickness of 0.0625 inch.

Tube = 1/ 2 inch OD, 3 / 8 inch ID

Exposed Tube length = 5.56 m

Circular Track width = 3 /4 inch

Theoretical Number of Semi-Circular Tracks = 37 / (3 / 4) = 49.3 tracks

The steam generator lower manifold cover has a small drain plug to allow drainage of trapped NaK from that manifold when service access inside that manifold is required.

Steam generator tube open cross sectional area:

= 198.91 inch^2

The nominal heat transfer area is:

Pi (3 / 8 inch)(.0254 m / inch) X 5.9 m / tube X 1081 tubes

= 190.85 m^2

CROSSSECTIONAL AREAS AND CONTAINED VOLUMES:

NaK volume contained in tubes:

198.91 inch^2 X (0.0254 m / inch)^2 X 6.0 m

= 0.77 m^3

NaK contained in manifolds:

(1.1 m + 1.0 m) X Pi(0.635 m /2)^2

= 0.6651 m^3

NaK Feed Pipe open area = Pi [(15.25 inch)/ 2]^2

= 182.65 inch^2

Open area inside shell = Pi(24 - 5.5 inch)^2 - 1081 tubes X Pi(0.25 inch)^2

= Pi (342.25 - 67.56) inch^2

= Pi (274.69 inch^2)

Note that for safety the jacket steel is 2 (3 / 8) inch = 3 / 4 inch thick. The spiral spacer must be designed to match the thermal characteristics of the tubes

The steam generator tubes normally contain liquid NaK. After fabrication the shell side of the steam generator should be hydraulic pressure tested at 15 MPa.

The tube side of the steam generator is filled with low presure NaK. We must be concerned about thermal stress arising from a tube temperature that is greater than the shell temperature.

Assume that each tube is 1 / 2 inch OD. Then the tube wall thickness is:

[(1 / 2inch) - (3 / 8 inch)] / 2 = (1 / 16 inch) = 0.0625 inch

For this tube size the single tube metal cross sectional area is:

Pi [(1 /4)^2 - (3 / 16)^2] inch^2

= Pi [16 / 256 - 9 / 256] inch^2

= Pi [7 / 256] inch^2

Thus the cross sectional area of the tube walls is:

1081 tubes X Pi (7 / 256) inch^2 / tube = 92.86 inch^2

The shell wall cross sectional area is:

Pi (24^2 - 18.5^2)

= Pi (576 - 336.7)

= 751.78 inch^2

Note that the metal cross sectional area of the shell is far greater than that of the tubes. Hence tube linear expansion must be matched by shell linear expansion for stress relief.

STEAM GENERATOR TUBE FAILURE:

In the event of a steam generator tube failure the higher pressure water/steam jets into the NaK where it immediately generates hydrogen gas and steam.

In normal operation the steam generator end manifolds contain NaK at below atmospheric pressure. On a steam generator tube failure the pressure source is the water at 10 MPa gauge, 310 degrees C to 320 deg C.

The the steam generator NaK manifolds each have a 16 inch OD tall vertical vent to the atmosphere via a tee, top ball check and rupture disk. These pipes allow emergency steam and hydrogen discharge and safely absorb credible NaK pressure pulses.

Rapidly forming steam and hydrogen bubbles will displace NaK forcing slugs of NaK to jet straight upwards before the steam and hydrogen are released to the atmosphere via a vent tee.

Eventually the NaK loop loses its excess pressure by discharge steam/hydrogen through the vents.

However, by then due to NaK drain down the steam generator tubes are filled with steam, not NaK.

On the occurrance of a steam generator tube failure high pressure water and steam both jet through the rupture into the tubes of the steam generator where they contact NaK and cause a rapid pressure rise in the NaK pressure. The rate of the pressure rise is mitigated by:

a)Use of narrow heat exchange pressure tubes which limit the water flow rate into the NaK;

b)Use of large diameter vents which open to vacuum and then the atmosphere.

It is difficult to realize good high temperature high pressure NaK seals at flanged mechanical joints. Hence in the sodium pool space normally the NaK operates at below ambient pressure. The NaK loop is rated for a higher pressure simply to ensure that there is no major damage when there is a steam generator tube rupture. It is possible that as a result of a major pressure pulse flange joints may leak argon or air into the liquid NaK, in which case the NaK must be drained down into its dump tank and the flange joint sealing must be fixed. The implication of this is that a steam generator tube failure may result in that heat transfer loop being out of service until the next reactor shutdown. However, the large number of independent heat transfer loops minimizes the consequence of a single heat transport loop shutdown.

This pressure relief arrangement protects the NaK loop from large steam or hydrogen induced NaK pressure pulses. Note that the 16 inch diameter pipes conveying NaK between the intermediate heat exchange bundle and the steam generator are designed so that normally the pressure difference between the sodium and the NaK is sufficient to prevent NaK entering the sodium in the event of an intermediate heat exchange tube failure.

INTERMEDIATE HEAT EXCHANGE BUNDLE TUBE FAILURE:

In the event of an intermediate heat exchange tube failure the NaK will become mildly radioactive, which should cause immediate NaK drain down to its dump tank.

As soon as a sensor which monitors the NaK level detects an out of range NaK level a valve opens which allows argon to exit the corresponding dump tanks.

STEAM GENERATOR MANIFOLD CALCULATIONS:

The NaK circuit internal pressure rating is limited by the pressure rating of the 18 inch flow tube of the induction pump which has a 0.375 inch wall thickness. At the working temperature the maximum allowable hoop stress in stainless steel is 39 MPa. The corresponding maximum NaK pressure Pm for the NaK loop is given by:

Pm (18.000 inch - 2(0.375 inch)) L = 39 MPa [2 (0.375 inch) L]

or

Pm = 39 MPa (0.750 inch) /17.25inch

= 1.695 MPa

Thus the NaK loop should be rated for a maximum working pressure of:1.7 MPa. The NaK loop should be subject to a 2.54 MPa hydraulic pressure test.

The NaK dump tanks can be lower pressure rated due to their ability to safely absorb transient pressure shocks.

The steam generator end manifolds form part of the NaK circuit. The end manifold ID is 37 inches. Let Wm be the manifold side wall thickness. Then for

Pm = 1.7 MPa

1.7 MPa (37.0 inch + W) = 39 MPa (2 W)

or

2 W (39 MPa + 0.85 MPa) = 1.7 MPa (37.0 inch)

or

W = 1.7 (37 inch) / 2(39.85)

= 0.7892 inch

Each manifold flange is 38.5 inch ID, 48 inch OD. The flange thickness is:

________

Each manifold cap is 48 inch OD and ___ inch thick. The manifold cap diameter subject to internal NaK pressure is about 40 inches diameter.

We need to calculate the temperature drop across the tube wall for Inconel 600.

CALCULATE THE TUBE WALL TEMPERATURE DROP

Wall thickness = 0.0625 inch

Exposed tube wall length = 6 m - 2(tube sheet thicknes)

The steam generator tubes normally contain liquid NaK. After fabrication the shell side of the steam generator should be hydraulic pressure tested at 15 MPa.

The tube side of the steam generator is filled with low presure NaK. We must be concerned about thermal stress arising from a tube temperature that is greater than the shell temperature.

Note that the metal cross sectional area of the shell is far greater than that of the tubes. Hence tube linear expansion must be matched by shell linear expansion for stress relief.

The NaK induction pump inlet is located close to the bottom of the NaK loop to ensure that it always has sufficient suction head pressure.

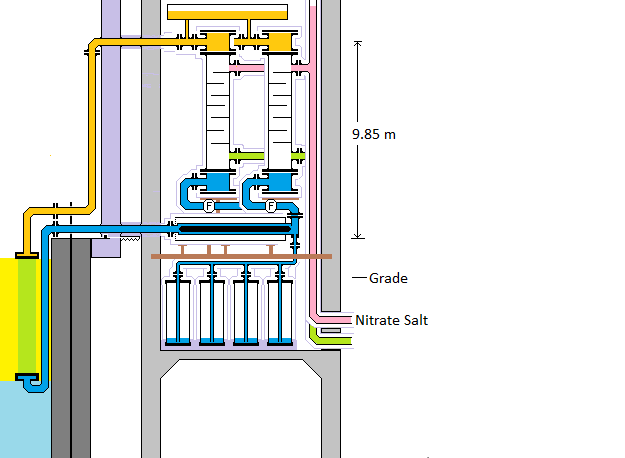

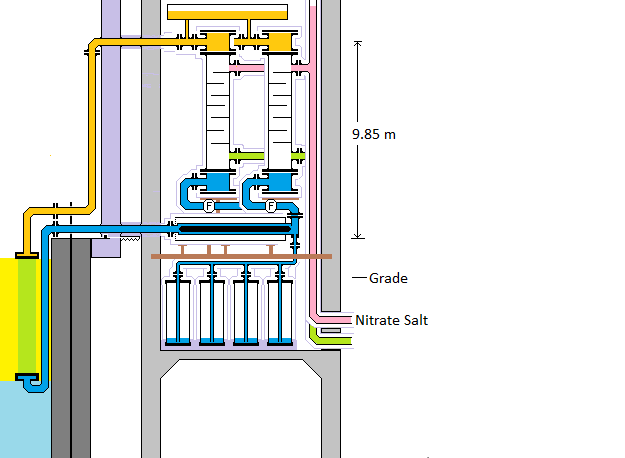

NaK DUMP TANKS:

Below the steam generators are NaK dump tanks for holding NaK to permit heat transport loop maintenance and fire suppression. If the argon pressure over the Nak dump tanks is released the NaK will drain down to below the induction pump level. This feature can be used to extinguish a NaK fire.

The NaK argon cover gas over the NaK dump tanks is installed with the system cool at an absolute pressure of about 0.2 MPa. This pressure will more than double at normal operting temperature. If this argon pressure rises to 0.8 MPa absolute for even a few milliseconds the loop safety shutdown sequence should be initiated.

There must be protection against NaK hammer in each heat transfer circuit.

The diagram shows that the exposed heat exchange tube length in the steam generator is:

5.70 m.

Steam Generator Positioning

The steam generators are positioned on two concentric circles.

Let Ri be the radius of the inner circle. The maximum center to center distance between the two adjacent steam generators on the inner circle is:

Pi (2 Ri) / 24

This is a contemplated average thermal flux through the FNR steam generator tubes of:

21 MWt / 204.9 m^2 = 0.103 MWt / m^2

By comparison, in a CANDU reactor the thermal flux to liquid wqter is:

2100 MWt /[380 fuel tubes X 12 bundles / tube X 0.5 m X 37 rods/bundle X Pi X 0.5 inch X .0254 m / inch]

= 2100 MWt / [151442.7 m inch X .0254 m / inch]

= 2100 MWt / 3364 m^2

= 0.624 MWt / m^2

Note that in a CANDU reactor the fuel is entirely surrounded by liquid water whereas in the contemplated steam generator only the bottom portion of the tubes is immersed in water so that at the tube bottom the heat flux per unit area is likely comparable to the heat flux per uit area at a CANDU fuel tube surface.

In steam generator design thermal stress relief is a major issue.

STEAM GENERATOR SHELL WEIGHT:

The approximate Steam generator shell weight exclusive of tubes, tube sheets and fittings is:

Rho Pi [(1.2 m / 2)^2 - (0.9 m / 2)^2] (5.56 m)

= Rho Pi [0.36 m^2 - 0.2025 m^2](5.56 m)

= Rho Pi [0.8757 m^3]

= (7.98 X 10^3 kg / m^3) Pi [.8757 m^3]

= 21.95 tonnes

STEAM GENERATOR COMBINED TUBE SHEET WEIGHT:

Rho Pi [(0.9 m)^2 - (1801)(0.00635 m)^2](.22 m X 2)

= Rho Pi [0.81 m^2 - .07262 m^2](.44 m)

= (7.98 X 10^3 kg / m^3) Pi (0.7374 m^2) (0.44 m)

= 8.13 tonnes

STEAM GENERATOR TUBE WEIGHT

Rho Pi (1801)[(0.5 inch)^2 - (0.375 inch)^2] (1 / 4) 6 m

= Rho Pi (1801) [[.02734 inch^2 ](6 m)(.0254 m / inch)^2

= Rho Pi (0.1906 m^3)

= (7.98 X 10^3 kg / m^3) Pi (0.1906 m^3)

= 4.78 tonnes

STEAM GENERATOR COMBINED MANIFOLD WEIGHT EXCLUSIVE OF END CAPS

STEAM GENERATOR COMBINED MANIFOLD CAP WEIGHT:

STEAM GENERATOR COMBINED FITTING WEIGHT:

STEAM GENERATOR TOTAL DRY WEIGHT:

MAXIMUM WEIGHT OF STEAM GENERATOR CONTAINED FLUIDS:

STEAM GENERATOR INSTALLATION:

Steam generators weighing about 40 tonnes are delivered to the site while lying horizontal on a flat deck truck. The truck backs under a horizontal beam. The steam generator is lifted clear of the truck deck. The truck drives away. The steam generator is lowered onto a dolly. The dolly is moved horizontally to a temporary parking position.

Then a mobile crane is engaged. The mobile crane lifts one end of the steam generator to make its long axis vertical. The mobile crane must then lift the steam generator sufficiently to clear the top of the outer structural wall, swing it to the desired position and lower it into the heat exchange gallery.

While being lowered the steam generator must to be rotated about its vertical axis so that its pipe connection flanges are correctly oriented.

TRANSPORTATION DELAY COMPENSATION:

The electricity output from a FNR is normally controlled by modulating the flow rate of the NaK through the intermediate heat exchange bundles and the steam generator.

There is a significant transportation time delay between a change in NaK flow rate through the intermediate heat exchange bundle and the corresponding change in rate of steam production.

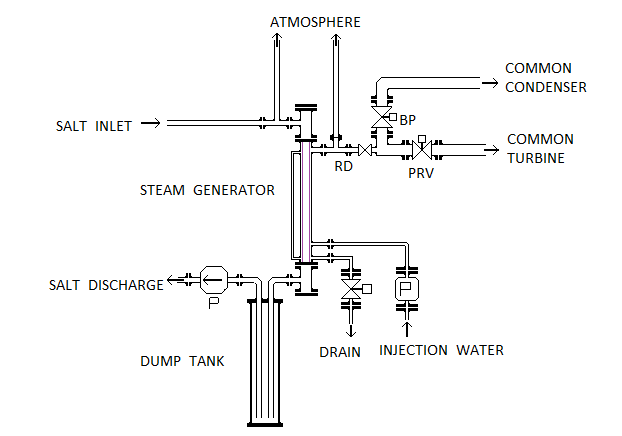

Hence the turbogenerator has a steam bypass valve (BP) to the condenser to fine adjust the turbogenerator speed and generator phase with no load before connecting the electricity generator to the grid.

Each steam generator has a local control loop that adjusts the steam pressure regulating valve (PRV) to attempt to maintain a steam pressure of 10 MPa in the steam generator which has the effect of controlling the steam generator water temperature at 320 degrees C.

The steam bypass valve must rapidly open to prevent dangerous turbine over speed if there is a sudden loss of electrical load on the turbogenerator. Even if the NaK flow rate through the intermediate heat exchanger is immediately reduced on loss of system electrical load there is a significant amount of thermal energy contained in circulating NaK and the steam generator that must be dissipated to prevent turbine over speed. That energy dissipation is achieved by bypassing steam to the condenser.

Each steam generator is fitted with a rupture disc that will vent steam to the atmosphere if the internal steam pressure exceeds the maximum safe working pressure for the steam generator shell.

Each steam generator has a local control loop which maintains the desired water level in the steam generator by controlling the rate of high pressure condensate water injection. In the event of a sudden pressure rise in the NaK loop, indicating a steam generator tube leak, the injection water flow is cut off and the steam generator drain valve is openned.

Up to six steam generators have their steam discharge ports feeding a common turbogenerator and their steam bypass ports feeding a common condenser. Ideally the turbogenerator should be rated for producing about 38 MWe.

DIAGRAM:

A diagram showing the connection configuration of one of six identical steam generators in each turbine hall is shown below. One FNR can support up to eight identical turbine halls.

During normal operation a steam pressure regulating valve (PRV) connected in line between the steam generator steam discharge pipe and the corresponding turbine keeps the steam pressure inside the shell at about 11.25 MPa. This pressure in combination with the properties of water keeps the super heated liquid water surface inside the steam generator lower shell at 320 degrees C.

Water is injected into the Steam Generator lower section at 260 C via injection pumps and a feedwater heater. The circulated HTF at up to 320 C heats this water up to about 315 C.

Also connected to the steam discharge pipe is a bypass (BP) valve to the condenser and a rupture disk vented to the atmosphere via a 12.75 inch OD schedule 160 pipe. The rupture disk is configured to rupture open at a steam pressure of about 14 MPa. The steam bypass valve also acts as a redundant over pressure safety valve. Thus there are two redundant means of protecting the steam generator from failure due to steam over pressure.

FNR STEAM GENERATOR NORMAL OPERATION:

The condensate injection pump inputs condensate water from the turbogenerator condenser at about 50 degrees C and at a pressure of less than 0.02 MPa and raises its pressure to about 10 MPa. This pressurized water flows first through the feed water heater tubes which raise its temperature up to about 260 degrees C before the water flow is joined by steam tapped off beteween the high and low presure turbines to another feed water pump and then to the steam generator second stage.

To minimize thermal stress in the tube wall it is essential to keep the temperature difference across the metal walls within the material rating by ensuring that the liquid water injected into the bottom of the lower steam generator shell is sufficiently warm.

In the bottom manifold of the steam generator there is NaK which is normally at a temperature of about 320 degrees C.

Cool input water from the feedwater heater flows into the steam generator lower section which warms the input water to about 312 C and vaporizes it before guiding the resuting steam upwards towards the steam generator upper stage tubes.

The lower portion of the tubed section of the FNR steam generator provides the water its latent heat of vaporization. The design object is to ensuring a layer of steam between the metal tube outer suface and the liquid water to limit the heat flux per unit area through the wall of the tube. Thus the temperature difference across the tube wall is minimized. The water evaporates from the surface of the bottom pool in the lower stage forming nearly saturated steam.

Outside the upper section steam generator tubes there is no liquid water. The heat transfer is from the hot tube outer surface to water vapor. The water vapor forms a thin boundary layer adjacent to the surface of the heat exchange tubes. The effect of this boundary layer is to reduce the temperature differential across the heat exchange tube wall. Hence the temperature of the heat exchange tube metal is close to the temperature of the NaK, so the tangential thermal stress within the heat exchange tube metal wall is small.

The tubed section of the steam generator upper stage act as a counter current heat exchanger which raises the temperature of the steam from its boiling point at about 312 deg C up to about 400 degrees C. At light loads this steam discharge temperature rises up to about 440 degrees C.

A pressure regulating steam valve located close to the steam turbine keeps the pressure inside the steam generator shell at 10 MPa. This vapor pressure in combination with the properties of water keeps the liquid water surface temperature at about 312 degrees C.

The upper portion of the steam generator must supply the sensible heat required to raise the steam temperature from 312 C to the steam generator discharge temperature of about 400 C. The upper stage tube bundle may also have to supply heat to vaporize small liquid water droplets that the flowing steam carries with it. It is important to vaporize these water droplets to prevent them eroding the down stream pipes and steam turbine.

At low thermal loads the NaK flow rate through the intermediate heat exchange bundle will be low. The NaK return temperature to the intermediate heat exchange bundle will be at a temperature close to 320 C and kept there by the pressure - temperature relationship maintained by the steam generator presssure regulating valve.

At high thermal loads the NaK flow rate through the intermediate heat exchange bundle is much higher. The NaK delivers more heat to the steam generator. The injection water pumps are forced to speed up to maintain the steam generator water level. However, the temperature difference across the steam generator heat exchange tube wall at the water level is never more than about 25 C.

The steam generator pressure regulating valve (PRV) attempts to maintain a steam pressure of 10 MPa inside the steam generator which has the effect of setting the steam generator water surface temperature at 312 degrees C.

If there is a sudden loss of electrical load on the turbogenerator a steam turbine bypass valve must rapidly open to prevent dangerous turbine over speed. Even if the NaK flow rate is immediately reduced on loss of system electrical load there is a significant amount of thermal energy contained in circulating NaK and steam that must be rapidly dissipated to prevent turbine damage due to over speed. That dissipation is achieved by bypassing steam to the condenser.

Each steam generator is fitted with a pressure relief valve (or rupture disc) that will vent steam directly to the atmosphere if the internal steam pressure exceeds the maximum safe working pressure of 12 MPa for the steam generator shell.

Each steam generator has a local control loop which maintains the desired water level in the steam generator by controlling the rate of high pressure condensate water injection. In the event of a sudden pressure rise in the NaK, indicating a steam generator tube leak, the injection water flow is cut off and the steam generator drain valve is openned.

Up to six steam generators can be connected in parallel to serve a common turbogenerator.

CONDENSATE AND EMERGENCY WATER INJECTION:

It is necessary to control each injection water pump to control the water level in each steam generator. Note that the time constant of this control loop should be short compared to the rate of change of the NaK through the intermediate heat exchanger which controls the reactor power output.

A key safety issue after loss of station power is to continue removal of fission product decay heat. That requires maintaining condensate injection water flow into some of the steam generators and maintaining the NaK flow.

On loss of station power sufficient NaK circulation must be maintained to to remove fission product decay heat. When city water is available the reserve cooling water tanks should be automatically refilled.

THERMAL PERFORMANCE:

At full thermal load the resulting temperature distribution is as follows:

Steam generator steam discharge temperature = 400 C

Steam generator water surface temperature = 312 C

Steam generator NaK inlet temperature = 450 C

Steam generator NaK discharge temperature = 330 C

Sodim discharge temperature = 460 C

Sodium return temperature = 330 C

HEAT EXCHANGE TUBE LINEAR STRESS REDUCTION:

In the steam generator the tubes run consistently warmer than the shell. This issue leads to compresive tube stress and tensile shell stress.

High temperature differentials across heat exchange tube walls can potentially cause thermal stress in excess of the material yield stress. Part of the steam generator design focuses on reducing the maximum material thermal stress.

There are two general approaches to heat exchange tube wall thermal stress reduction. At the bottom of the steam generator shell , where the heat exchange tubes are surrounded by liquid water, external sleeves around the tubes are used to reduce the heat flux per unit area and hence the maximum temperature drop across the tube wall.

Higher up the tubes but still below the water level there is a layer of steam adjacent to the outside surface of the heat exchange tube which reduces the heat flux per unit area through the tube wall. Hence in this region the tube wall temperature is close to the downward flowing molten salt temperature. The heat flux through the tube wall is limited by the rate of heat transfer from the tube wall to steam, which is much less than the rate of heat transfer from the tube wall to liquid water.

The height of the water inside the steam generator is indirectly controlled by controlling the height of a pure liquid water column in an external tube connected between the top and bottom of the shell. This external tube has no radial heat flow. That external water column height is sensed and is controlled by controlling the flow rate of high pressure water injection into the steam generator spray injection nozzles.

Due to steam bubble formation the height of the water inside the shell is several times the height of the sensed water column in the external water level sensing tube. However, the pressure at the bottom of the two water columns is identical.

Below the top of the interior water level heat transferred from the tube outside wall to the steam is almost immediately absorbed by latent heat of evaporation of water that is transitioning from water to steam. Thus below the top of the water level the liquid temperature is nearly constant at about 310 degrees C at a pressure of 10 MPa, corresponding to saturated steam. The head pressure is maintained by the steam pressure regulating valve.

Above the top of the liquid water the steam becomes drier and rises to a top temperature in the range 400 degrees C to 440 degrees C depending on the system thermal load.

LOWER MANIFOLD THERMAL STRESS MITIGATION:

There is feed water temperature mixing in the bottom of the steam generator shell to minimize thermal stress on the steam generator heat exchange tube portions that pass through water. The feed water temperature rise from 25 deg C to 320 C is partially realized by feed water heat recouperation from the turbine discharge steam immediately upstream from the turbine condenser followed by water mixing at injection into the steam generator.

TUBE FAILURE PROTECTION AND MITIGATION:

In a continuously operating energy generation system sooner or later there will be a steam generator heat exchange tube failure. Such a failure will potentially allow high pressure water to flow through the rupture and into the molten salt.

There must be molten salt pressure relief vents at the steam generator and at the NaK-salt heat exchanger of sufficient size to limit the consequent rapid rise in pressure in the molten salt circuit sufficiently to prevent equipment damage.

An important issue in FNR steam generator design is preventing a water leak from a steam generator tube rupture from causing a serious accident. When high pressure water and steam jets into the low pressure hot molten salt the molten salt is propelled at a high speed toward the atmospheric vents.

COLD SHUTDOWN SEQUENCE:

The system must be designed to:

1) Remain structurally safe in the presence of NaK hammer;

2) Prevent a dangerous pressure transient reaching the connected intermediate heat exchange bundle;

3) In the event of tube damage to the steam generator the system must

rapidly and safely vent the steam (and possibly hydrogen) to prevent water entering the NaK circuit and causing yet more damage.

4) Open a steam generator drain valve and use the residual steam pressure to rapidly expel liquid water from the steam generator shell into the drain;

5) Turn off the injection water pump to stop the injection water flow;

6) Release high pressure steam from the steam generator shell to the condenser to stop water / steam jetting into the NaK rom both sides of the steam generator tube rupture;

7) Force the steam pressure regulating valve fully closed to prevent steam from other steam generators back flowing through the steam pressure regulating valve;

8) Turn off the NaK induction pump to block further heat input from the reactor;

9) Drain the NaK to its dump tanks;

10) Safely isolate components for cleanup and repair.

RESTART SEQUENCE:

11) Confirm correct NaK level before restarting the NaK induction pump at a low flow.

12) Apply argon pressure over the dump tanks to refill the NaK loop;

13) Start the NaK circulation pump;

14) Close the steam generator drain valve;

15) Enable the steam generator injection water pump;

16) Use the steam bypass valve to synch the generator to the line;

17) Close the generator main contactor;

18) Increase the NaK flow to achieve the desired generator power.

There must be fully redundant pressure relief safety devices (rupture disks) to ensure NaK pressure safety because failure of the motorized valves to work as contemplated could otherwise have serious consequences. In addition to steam pressure sensors there must be water level sensor and a molten salt level sensor at the steam generator to to control the injection water pump and to sense a transient increase in molten NaK pressure caused by a steam generator heat exchange tube leak.

HEAT EXCHANGE TUBE RUPTURES:

The worst FNR nightmare is an event which causes water from the steam circuit to flow backwards through either the salt or HTF circuits, through the NaK circuit and into the primary sodium pool. Such an event could only occur if both salt or both HTF vents were blocked such that the steam generator pressure could cause water to rupture a steam generator tube, propagate backwards through the salt or HTF pipes, rupture a NaK-salt heat exchanger tube, propagate backwards through the NaK piping, and rupture an intermediate heat exchange tube. This accident condition requires three simultaneous heat exchange tube failures and two atmospheric vent blockages in the same heat transport circuit.

The purpose of the system safety design is to prevent such an accident ever happening. Even if the tubes in both the steam generator and the NaK-salt heat exchanger simulataniously rupture the higher pressure in the NaK circuit and the NaK circuit pressure relief should prevent such an accident occuring.

The salt and HTF circuit pressure relief pipes must be large enough (12 inch diameter) to ensure that nitrogen (and perhaps hydrogen) can be vented as fast as they can be generated, which in the case of effects of a Nak-salt heat exchanger tube rupture and/or a steam generator tube rupture are limited by the maximum possible water and NaK flow rates through the throats of the ruptured heat exchange tubes.

The worst case consequence of any potential steam generator or NaK-salt heat exchanger tube rupture are physically limited by the use of 48 independent heat transfer circuits.

Note that the liquid water flow through a steam generator heat exchange tube rupture and into the salt will stop when the steam generator is partially drained. However, the steam flow through both sides of the tube rupture will continue until all the steam in the steam generator shell is vented. The over pressure in the salt should cause the steam bypass balve to the condenser to discharge steam from the steam generator shell as fast as possible so that steam does not continue to flow into the salt.

The steam pressure regulating valve (PRV) needs to be fully closed to prevent steam back flow from other steam generators.

STEAM GENERATOR SHUTDOWN:

1) The shell side of the steam generator contains super heated liquid water on the bottom and steam on top.

2) The NaK feeds into the top manifold and then into the tubes. The NaK flows downwards through the tubes before exiting via the lower manifold. This NaK is hot on top and cooler near the bottom. The NaK flow inside the tubes is turbulent for good heat transfer.

3) In the event of a tube crack the corresponding 0.5 inch diameter tube holes in the tube sheet limit the rate of flow of high pressure water into the low pressure NaK.

4) The top and bottom manifold flange outside diameters are approximately twice the inside diameter of the shell side of the steam generator. The manifold top and bottom covers are removable and are held in place by a large number of perimeter bolts. These manifold covers need special NaK resistant gaskets.

5) The bottom of the steam generator shell contains superheated water. The shell injection water inlet and shell steam discharge ports are on the side of the shell.

6) A external tube connected between the steam discharge port and the high pressure injection water inlet port contains a water level sensor that is used to control the injection water flow rate.

7) The shell steam discharge port goes to a tee branch. The bottom main axis port of the tee goes to a pressure regulating steam discharge valve, which attempts to maintain 10 MPa steam pressure in the shell.

8) The upper port of this tee goes to a rupture disk that will vent steam from the shell to the atmosphere if the steam pressure regulating valve fails to operate properly.

9) If a steam generator tube rupture occurs the high pressure water jets into the low pressure NaK and immediately forms steam. The steam drives some of the NaK up vents to enable steam and hydrogen release to the atmosphere.

10) On the occurance of a rise in pressure in the tube side of the steam generator electric power to the high pressure water injection pump is cut off and the steam generator shell drain valves that are held closed by solenoids open under the water/steam pressure.

11) The steam pressure in the steam generator shell drives liquid water in the bottom of the steam generator shell to the drain.

12) Liquid water will continue to jet through the heat exchange tube rupture and into the NaK until the water level in the shell falls to the bottom of the tube rupture. Hence it is essential to drain the shell as fast as possible.

13) Even after the water level in the shell is reduced residual steam will leak into the NaK from both sides of the heat exchange tube rupture as long as there is steam pressure in the shell. Hence the shell steam pressure must be rapidly reduced to zero by reducing the setpoint of the steam pressure control valve.

14) There are redundant NaK pressure relief vents over the steam generator to relieve over pressure in the NaK circuit.

TUBE FAILURE FLOWS:

Assume a heat exchange tube size of 0.500 inch ID.

Tube open cross sectional area

= Pi (.25 inch X 0.0254 m / inch)^2

= 1.2667 X 10^-4 m^2

In a tube:

Flow power = force X velocity

= (pressure X area X velocity)

Flow power = kinetic energy / unit time

= (mass / sec) X (velocity)^2 / 2

= (density X area X velocity X (velocity)^2 / 2

Equating the two expressions for flow power gives:

pressure = density X velocity^2 / 2

or

Velocity = [2 X pressure / density]^0.5

or

volumetric flow rate = area X [2 X pressure / density]^0.5

or

mass flow rate = density X area X [2 X pressure / density]^0.5

= area X [2 X pressure X density]^0.5

Hence the maximum flow rate of super heated water through a single heat exchange tube in a single direction is:

= 1.2667 X 10^-4 m^2 X [ 2 X 11.25 X 10^6 Pa X 1000 kg / m^3]^0.5

= 1.2667 X 10^-4 m^2 X [2 X 11.25 X 10^6 kg m /s^2 m^2 X 1000 kg / m^3]^0.5

= 1.2667 X 10^-4 m^2 X 15 X 10^4 kg / s m^2

= 19.0005 Kg / s

In a tube failure situation the tube will leak in both directions into the NaK. Thus immediately after a single tube collapse superheated water may enter the salt at:

2 X 19 kg / s = 38 kg / s

This water will immediately flash to steam.

At 0 degrees C, 1 atmosphere (.101 MPa), one mole (18 gm) of water vapor occupies 22.4 lit. At 430 deg C one mole of water vapor at one atmosphere (0.1 MPa) occupies [(430 + 273 ) / 273] X 22.4 lit = 57.68 lit.

At 430 deg C, 2 MPa one mole of steam occupies:

57.68 lit / 20 = 2.884 lit

Recall that:

mass flow rate = area X [2 X pressure X density]^0.5

Thus at 2 MPa the maximum water vapor mass flow venting rate is:

mass flow rate = 0.10382 m^2 X [2 X 2 X 10^6 Pa X 18 g / 2.884 lit]^0.5

= 0.10382 m^2 X [2 X 2 X 10^6 kg m / s^2 m^2 X 6.241 kg / m^3]^0.5

= 0.10382 X 4.996 X 10^3 kg / s

= 518.7 kg / s

Thus under these circumstances the maximum tolerable number of simultaneous steam generator tube failures is:

(518.7 kg / s) / 38 kg / s-tube failure) = 13.65 tube failures

When a heat exchange tube initially fails salt will be discharge from the vent like it is shot from a blowgun. There will be a slug of salt about 10 m long. An important questionis will it be accelerated fast enough to prevent nitrate salt vent failure due to over pressure.______________

This steam pressure will create a pressure pulse in the NaK exhaust vent which blows NaK out its top. That vent and its connected piping must be robust enough to withstand the pressure pulse.

Assume that the vent pipe is 16.000 inch OD schedule 80 (0.843 inch wall) so the ID is 14.314 inch. Then the volume of that pipe is:

Pi (14.314 inch / 2 X .0254 m / inch)^2 X L

= 0.10382 m^2 L

Hence if L = 10 m the vent pipe will reach its maximum safe pressure of 1.7 MPa in about:

= 2.52 s__________

Thus on the occurrence of a single heat exchange tube failure the 16 inch ball check must move from full closed to full open in about _____ seconds.

On the occurance of a steam generator heat exchange tube failure the 1st object is to reduce the liquid water level in the steam generator shell as fast as possible so that only steam feeds the rupture. The second object is to reduce the steam pressure in the steam generator shell as fast as possible to limit the mass of steam ultimately injected into the NaK via the tube rupture.

WATER MASS FLOW RATE:

During normal operation each steam generator must supply:

1000 MWt / 48 = 20.833 MWt of heat to water flowing through it.

20.833 MWt

= [(380 deg C X 1 cal / gm deg C X 4.186 J / cal) + (1200 J / gm)] [flow rate]

or

[flow rate]

= [20.833 X 10^6 J / s] / [(380 deg C X 1 cal / gm deg C X 4.186 J / cal) + (1200 J / gm)]

= [20.833 X 10^6 gms / s] / [(380 X 4.186) + (1200)]

= [20.833 X 10^6 gms / s] / [2790.68]

= 7465.21 gms / s

= 7.465 kg / s

FNR STEAM GENERATOR EMERGENCY SHUTDOWN ISSUES:

In normal operation the steam generator shell side contains high pressure (10 MPa) water/steam. However, the shell should be hydraulic pressure tested to at least 15.0 MPa to safely manage 10 MPa maximum possible stea

a) The NaK loops, if working pressure rated for 1.7 MPa, can safely manage a single high pressure water/steam tube rupture by venting steam and hydrogen.

b) Stopping of the injection water pump. There are two series connected pump control relays activated by independent high pressure sensors for certainty in stopping high pressure water injection into the steam generator;

c) Openning the steam generator drain valve;

d) Opening of the steam bypasses valve to the condenser.

e) Stopping the NaK induction pump and draining the NaK to its respective dump tanks prevents further heating of the steam generator by the reactor and thus limiting the total amount of transient heat that must be dissipated.

f) Complete closing of the steam pressure regulating valve (PRV) prevents reverse steam flow through the pressure regulating valve.

STEAM GENERATOR THERMAL STRESS RELIEF:

In this design the steam generator tubes operate in compression, so there is no creep failure.

The NaK loop temperature differential may be 120 degrees C but the temperature differential across the steam generator tube walls below the water level should be under 20 degrees C. One way of reaching this objective is to keep the liquid water that is in contact with the heat exchange tubes at its boiling point so that the heat exchange tubes under the water surface are covered with steam bubbles. However, that means that incoming water must be preheated before it contacts the exposed heat exchange tubes. It is contemplated that the lower portions of the heat exchange tubes in the steam generators will be sleeved to reduce thermal stress.

By keeping a layer of steam between the heat exchange tubes and the water in the base of the steam generator the local heat flux through the tube wall is reduced. It is necessary to keep the temperature differential across each heat exchange tube wall under 20 degrees C to limit wall stress.

TUBE SHEET CURLING

The temperature drop across the tube sheet thickness leasds to tube sheet curling. This effect places different axial stress on central tubes than on perimeter tubes. At the top manifold the NaK is consistently warmer than the steam so the perimter of the top manifold bends down with respect to the manifold center. At the bottom manifold the water is consistently cooler than the NaK which causes the lower mnifold perimeter to bend upward with respect to the manifold center. Hence for the steam generator tube bundle these two effects are additive.

WELDING:

The steam generator manifold welds must be deep penetration equal in quality to the welds used on high pressure natural gas distribution pipelines. Possibly a helium leak detector should be used for confirming weld quality.

EROSION MINIMIZATION:

As the water/steam mix moves through the steam generator the water/steam ratio decreases and the fluid velocity increases. A major source of steam gemerator wear is tube surface erosion due to impact by high velocity water droplets. Thisissue is particuarly relevant near the steam discharge port.To mitigate this problem the steam dischage pipe shuold hae an inside taper at the steam discharge port such that the cros sectional area at the port is:

Pi (4 inch)^2 rather than Pi (3 inch)^2

Similarly the internal baffle spacing should be larger near the steam discharge port than near the internal water surface.

STEAM AND INJECTION WATER PIPE SIZING:

The steam discharge pipe must be rated for a working pressure of 10 MPa. From a steam table the corresponding saturated water temperature is 312 degrees C.

The required heat flow is 21 MWt or [(21 X 10^3) / 1.0543 ] BTU / s

From a steam table the steam enthalpy is (1172.6 / 0.28827) BTU / ft^3

Hence the required steam volumetric flow rate is:

[(21 X 10^3 X 0.28827) / (1.0543 X 1.1726)] ft^3 / s

=4.8967 ft^3 / s

A pipe with an inside diameter of 6 inches has a cross sectionalarea of:

Pi [(1 / 4) ft]^2 = (Pi / 16 ft^2)

Thus the steam velocity in that pipe is:

[4.8967 ft^3 / s] / (Pi / 16 ft^2)

= 24.938 ft / s

That is the velocity that water droplets carried by the steam will impact 90 degree pipe elbows. Hence a suitable steam pipe is 8 inch OD, 6 inch ID.

At 312 degrees C from steam tables the ratio of of water to density of saturated steam is:

(.28827 / .02328) = 12.383

Hence in a 6 inch ID pipe the inlet waterflow rate would be:

(24.938 ft / s / 12.383) = 2.0139 ft / s

With a 3 inch ID pipe the water flow rate would be:

4 x 2.0139 ft / s = 8.055 ft / s = 2.455 m / s

Hence use an inlet water pipe which is about 4 inch OD, 3 inch ID, has a 8 inch diameter flange.

SECOND STAGE INJECTION WATER HEATING:

To minimize thermal stress in the steam generator it is desirable to mix the source injection water with 312 deg C water before allowing the water mix into the bottom of the steam generator. This objective can be achieved by having an injection water port on the steam generator sized for 8 inch OD pipe.

A length of 8 inch OD pipe feeds this port. At the upstream end of this 8 inch OD pipe length is a blanking plate fitted for joining to the 4 inch OD injection water source pipe. Within this 8 inch OD pipe length is a venturi arrangement for mixing cool source injection water with 312 deg C water before this water mix hits the steam generator tubes.

This web page last updated November 7, 2025

| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|