| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|

INTRODUCTION:

The insertion depth of the movable fuel bundles into the matrix of fixed fuel bundles sets the average fuel temperature. The main function of FNR Actutors is to occasionally adjust the insertion or withdrawal of movable fuel bundles into the matrix of fixed fuel bundles to compensate for fuel aging or to temporarily reduce the reactor operating temperature to enable fuel shuffling or intermediate heat exchange bundle replacement.

The FNR Actuators are used to set the insertion depth of the movable fuel bundles so as to achieve the desired fuel temperature at low thermal power. Thereafter the FNR average fuel temperature is regulated by thermal expansion/contraction of the FNR fuel assembly.

Linear thermal expansion of steel is typically about 10 ppm / degree C. If the reactor setpoint is being regulated to within +/-10 degrees C and if the core zone width is typically 10 m then the fractional core zone area change due to thermal expansion at the setpoint temperature is about:

2 X (+/-10 degrees C) X 10 X 10^-6 / deg C = +/- 2.0 X 10^-4

Hence for a 0.5 m core zone length the play, hysterisis and position error of the actuator must be comparable to:

2 X 10^-4 X 0.5 m = 0.1 mm.

The actual insertion of each movable fuel bundle into the matrix of fixed fuel bundles is monitored using a precision laser scanner, similar in operation to a laser measuring tape. This distance measurement establishes an initial position set point. Any subsequent deviation of the actual position from this set point results in a control signal to the actuator to return it to its position setpoint.

A FNR Actuator is a constantly loaded hydraulic piston that raises or lowers a movable fuel bundle over a range of 1.1 m for controlling insertion of that movable fuel bundle from the matrix of fixed fuel bundles. This insertion must be precise, smooth and hysterisis free. The weight of the movable fuel bundle less its buoyancy force in liquid sodium less the buoyancy force caused by its indicator Indicator Tube is constantly acting downwards on the piston type actuator. That force is balanced by the liquid sodium pressure in the actuator cylinder and the actuator piston cross sectional area. The mass of a FNR movable fuel bundle is about 1.7 tonnes. A hysterisis free vertical position resolution of about:

0.1 mm = 100um

is desired.

The actuator consists of two ~ 1.5 m long vertical pipes, one which loosely slides loosely inside the other. The bottom of the larger pipe is sealed closed except for the connection of the hydraulic fluid tube. The bottom of the inner pipe, which is the fuel bundle support pipe, is closed with a compressible piston. The top of this pipe is firmly attached to the base of a movable fuel bundle. Increasing the hydraulic fluid volume under the piston raises the movable fuel bundle. Lowering the hydraulic fluid volume under the piston lowers the fuel bundle. The hydraulic fluid volume under each piston is set by an argon controlled sliding valve that can inject more hydraulic fluid fluid, isolate the contained hydraulic fluid line or drain the hydraulic fluid.

When the control argon pressure drops to zero (such as during a loss of house power), the hydraulic fluid drains causing the movable fuel bundles to retract.

The outer pipe has an OD of 8.625 inch and a wall thickness of 0.406 inch.

The inner pipe (The fuel bundle support pipe) has an OD of 7.625 inch and a wall thickness of 0.875 inch.

The outer pipe ID is:

8.675 - 2(.406) = 7.863 inch = 0.1951 m

and the inner pipe ID is:

7.625 inch - 2 (.875) = 5.875 inch.

The required piston OD is 7.863 inch. Use a compressible piston where the weight of the movable fuel bundle causes the piston to expand to seal with the ID of the larger pipe.

The piston cross sectional area is:

Pi (7.863 inch)^2 / 4 = 48.5585 inch^2

= 0.03133 m^2

The desired resolvable change in trapped fluid volume is:

0.03133 m^2 X 10^-4 m

= 3.133 X 10^-6 m^3

= 3.133 cm^3

which is the minimum required volume resolution of the liquid sodium control valves.

At the top of the inner pipe are vertical fins that connect the inner pipe to the projecting corner legs of the movable fuel bundle.

The sodium pressure required to lift the movable fuel bundle is given by:

[1.7 tonnes x 1000 kg / tonne X 9.8 m / s^2] / [0.03133 m^2]

= 531.758 kPa

= 5.4 atmospheres

= 77.4 psi.

Both of these pipes must be firmly attached due to high bending torque

Simple thermal expansion of a fuel rod over 5 deg C is about:

(20 X 10^-6 / deg C) x 5 deg C X 300 mm = 0.03 mm

Both of these pipes must be firmly attached due to high bending torque

The amount of movable fuel bundle insertion must be constantly monitored. If the insertion depth signal is lost even briefly the movable fuel bundle must be withdrawn, which is the default condition.

The hydraulic line is fitted with a rupture disk. If a large weight falls on the indictor tubes the rupture disk will fail causing withdrawal of the affected movable fuel bundles.

A feature of this arrangement is simplicity and a single control tube per movable fuel bundle.

The reactor setpoint temperature is controlled by the amount of movable fuel bundle insertion into the matrix of fixed fuel bundles. This net insertion is a function of the difference in length between the actuator and the fixed fuel bundle supports.

A condition that we need to avoid is zero power setpoint drift. If at zero power the temperature of the contained hydraulic sodium causes the movable fuel bundle to net insert further into the matrix of fixed fuel bundles then the setpoint will spontaneously rise. To avoid this problem:

(TCE of the actuator) X (actuator length) < (TCE fixed fuel bundle support) X (fixed fuel bundle support length)

If both are formed from the same material this condition is normally met because generally:

(actuator length) < (fixed fuel bundle support length)

If these conditions are met a rising sodium pool temperature tends to reduce the reactor temperature setpoint which provides negative feedback for setpoint stability.

For the same reason Earthquake induced changes to the vertical displacement of movable fuel bundles with respect to fixed fuel bundles must be kept less than 1 mm to prevent an earthquake from initiating a prompt neutron critical event causing sodium void instability.

This area will be slightly reduced by the spiral wire winding and by cumulative fuel tube swelling.

To obtain the required bending resistance we choose a movable fuel bundle support pipe which has an OD of 7.625 inch and a wall thickness of 0.875 inch.

The open area potentially available around the outside of this pipe is:

[19 (9 / 16) inch]^2 - Pi [7.625 inch / 2]^2

= 114.222 inch^2 - 45.66 inch^2

= 68.56 inch^2

Hence the 7.625 inch OD pipe cross section should not significantly impede the vertical sodium flow provided that sodium can flow laterally over the top of the movable fuel bundle support pipe.

The actuators fit into the open steel lattice that supports the FNR fuel bundles.

The open steel lattice has a clearance hole that stabilizes the top of the retracted support pipe ~ 1.5 m above the bottom of the open steel lattice.

The movable fuel bundle grating area potentially obstructed by the movable fuel bundle support pipe is:

Pi (7.625 inch / 2)^2

The entry area for sodium flowing over the top of the movable fuel bundle support pipe is:

Pi (7.625 inch) D

where D is the minimum axial distance between the top of the support pipe and the bottom of the grating. In order to maintain the same cross sectional area for sodium flow:

[Pi (7.625 inch) D] / [Pi (7.625 inch / 2)^2] = 0.651 = fractional open area

The fractional open area is:

{[9 / 16)inch]^2 - Pi {(3 / 16)inch]^2 / [(9 / 16) inch]^2

= (81 - 9 Pi) / 81

= 0.651

Hence:

or

4 D / 7.625 inch = 0.651

or

D = 7.625 inch (0.651)/ 4

~ 1.24 inch

For certainty we should make this gap between the support pipe and the grating at least 1.5 inches.

Changing the sodium hydraulic pressure causes the inner pipe to move up and down over a height range of about 1.1 m. The 7.625 inch OD, round movable fuel bundle support pipe slides loosely inside the outer cylinder pipe.

The rupture disc is chosen so that it will fail if the vertical force becomes too large, as in a vertical impact to the FNR fuel assembly that might affect its relative fuel geometry. Such an impact might result from a ground penetrating bomb dropped from a high altitude.

When the rupture disc fails gravity will cause the movable fuel bundle to fall to its fully retracted position.

The movable fuel bundle support pipe and piston slide into the open pipe within the actuator. This open pipe provides the movable fuel bundle lateral stability when the movable fuel bundle is totally retracted (at its lowest position) and the adjacent fixed fuel bundles are not present during fuel loading and unloading periods. The bottom of the piston is slightly conical to assist in blind insertion of the movable fuel bundle support pipe into this hole. The outer pipe projects slightly to assist in blind insertion of the movable fuel bundle support pipe.

The liquid sodium hydraulic pressure tube feeding each actuator is routed along the bottom of the open steel lattice.

The required hydraulic pressure is provided by a feed from a pressurized liquid sodium tank which feeds a common high sodum pressure manifold.

Each actuator has a dedicated sodium hydraulic feed/drain tube. To insert a movable fuel bundle into the matrix of fixed fuel bundles a NC valve connects the high pressure manifold to the movable fuel bundle control tube.To withdraw the fuel bundle a NO valve connects this tube to the sodium pool. These valves share a common body and are activated by argon prssure.

Loss of station control power causes movable fuel bundle withdrawal and hence reactor cold shutdown.

A movable fuel bundle has a mass of about 1.7 tonnes. Hence the actuator must be sufficiently robust to dependably support, position and stabilize this mass. When the movable fuel bundle is fully withdrawn the movable fuel bundle support pipe must keep the movable fuel bundle vertical. The outer pipe and the movable fuel bundle support pipe must both be of sufficient diameter and thicknes that they will not fail due to worst case shear force. Hence the need for a 8.625 inch OD schedule 60 cylinder and a 7.625 inch movable fuel bundle support pipe.

An advantage of this actuator design is that there is almost no vertical movement hysterisis. When there is no hydraulic fluid flow to the actuator, apart from piston seal leakage the movable fuel bundle remains at its last set vertical position. This mechanical configuration provides good FNR fuel geometry stability.

The actual vertical position of each movable fuel bundle is monitored via an overhead scan of the elevation of the corresponding indicator tube top. This monitoring system also monitors the indicator tube temperature.

DIMENSIONS:

The hydraulic tubing must be routed behind and between the intermediate heat exchange bundles such that in an earthquake the fuel assembly can move horizontally with respect to the sodium pool walls at least 0.5 m in any direction without the hydraulic lines sustaining any physical damage. This hydraulic tubing should be routed through conduits for physical protection where it crosses over the pool deck.

The hydraulic fluid withdrawal control valves should be normally open and the insertion control valves

should be normally closed so as to default to the withdrawn position on loss of station power. These valves exist in a 500 degrees C environment and are remotely operated by argon pressure.

Assume that the hydraulic tubes are evenly spaced around the perimeter of the sodium pool. Then the average tube to tube center to center distance is:

[Pi (20 m) - 8 m] / [ (464 movable bundles)] = 0.118 m

That is sufficient space for 0.25 inch ID tubing with compression fittings.

HYDRAULIC ACTUATOR POSITION:

The hydraulic acuator should be supported and oriented so that its fluid port is at its bottom center. The hydraulic tubing should be routed to vent unwanted air near the control valve.

ACTUATOR PERFORMANCE STABILITY:

It might be prudent to have an automatic test sequence that from time to time sequentially runs every movable fuel bundle up and down by a controlled amount to demonstrate that the actuators continue to work as designed and that the fuel bundles or actuators have not been subject to swelling or other problems that might cause a movable fuel bundle to jam.

MECHANICAL RIGIDITY CONSIDERATIONS:

A major issue in fuel bundle design is horizontal mechanical stability and rigidity because the overall fuel bundle height of 8.0 m is much greater than its width (.2715 m or 0.3286 m). Hence, the mechanical design of the fuel bundles is important to ensure that during fabrication, transport, installation and operation the fuel bundles do not bend, warp or otherwise deform. Such bending or warping might potentially cause a jam in the vertical sliding of a movable fuel bundle within the surrounding matrix of fixed fuel bundles.

A fixed fuel bundle has corner girders which extend down below the fuel tubes to also serve as support legs. These legs attach to the internal diagonal plates that provide central support and to an upper central lifting point. On installation the corner girders of fixed fuel bundles connect to adjacent fixed fuel bundles via diagonal bolts at the top of each corner girder. The fixed fuel bundles are held in place on top of the open steel lattice by cross fittings. The cross fittings fit inside the fixed fuel bundle legs and are tapered at their tops to allow practical blind mating with the fuel bundle support legs.

The corner girders of every fixed fuel bundle extend downwards ___ m below the bottom of the fuel fuel tube support grating. At the top of the fuel bundle 0.4 m diagonal sheet extensions provide lifting points for fuel bundle installation and removal. Short corner girder upward extensions allow use of diagonal bolts for horizontally connecting together adjacent fixed fuel bundles.

The entire weight of the fixed fuel bundles is supported by the four fuel bundle legs which are stabilized below the gratings by diagonal members. These legs extend __m below the fuel tube bottoms to allow liquid sodium to easily flow into the bottom of the fuel bundles and to minimize long term neutron damage to the open steel lattice.

In operation the weight of each movable fuel bundle is borne by the 7.625 inch OD fuel bundle support pipe which sets the maximumm amount of the movable fuel bundle's insertion into the matrix of fixed fuel bundles. The movable fuel bundle travel is limited at the bottom by its 1.1 m of projecting support pipe length after an allowance of 0.4 m for the grating, support pipe to grating clearance and support pipe adapter plates.

SUPPORT PIPE BENDING RESISTANCE:

W = pipe wall thickness = 0.875 inch

R = average pipe radius = [7.625 inch / 2] - [0.875 inch / 2] = 3.375 inch< BR>

Theta = angle about pipe center

dA = W R d(Theta)

Bending resistance = 2 Integral from Theta = 0 to Theta = Pi of:

[R sin(Theta)] W R d(Theta) Pmax

=Integral from Theta = 0 to Theta = Pi of:

[2 W R^2 Pmax sin(Theta)] d(Theta) Pmax

= 2 W R^2 Pmax [(-cos(Pi)) - (-cos(0))]

= 2 W R^2 Pmax [1 - (-1)]

= 4 W R^2 Pmax

W = 0.875 inch

R = 3.375 inch

Pmax = 10,000 lb / inch^2

Hence:

4 W R^2 Pmax = 4 (.875 inch) (3.375 inch)^2 (10,000 lb / inch^2)

= 398,672 lb-inch

= 398,672lb-inch X (.0254 m / inch) x (.454 kg / lb)

= 4597.32 kg-m

For the outside cylinder pipe:

W = 0.402 inch

R = (8.625 + .402) / 2 = 4.5135 inch

These bending resistances are barely sufficient to allow a crane to lift one end of a horizontal movable fuel bundle without that bundle buckling.

PASSIVE FUEL BUNDLES:

In order to achieve fuel bundle mounting interchangability the passive fuel bundles are the same physical size and are mounted in the same manner as the active fuel bundles. However, the passive fuel bundles are supported by open steel lattice components so that they are not movable and remain in a fixed position with respect to the fixed fuel bundle matrix.

HORIZONTAL FUEL ASSEMBLY MOVEMENT CLEARANCE:

In an earthquake it is important for the fuel assembly to be able to slide horizontally at least one m before there is a collision between the fuel assembly and an intermediate heat exchange bundle assembly. The actuator hydraulic tubes must have sufficient slack at the bottom of the sodium pool to permit this relative motion.

FNR ACTUATOR REPLACEMENT

Sooner or later a particular FNR Actuator will need replacement. All such actuators must fit into an equipment transfer airlock.

The internal width of an equipment tranfer airlock must be about 1.5 m to accommodate intermediate heat exchanger radial piping and the 42 inch intermediate heat exchange bundle manifold width.

The open steel lattice is fabricated in sections that are field assembled.

The open steel lattice modules must smoothly

fit together. There may be significant merit in making the open steel lattice modules that support active fuel bundles and cooling bundles 2 (9 / 16) inch wider than the other modules.

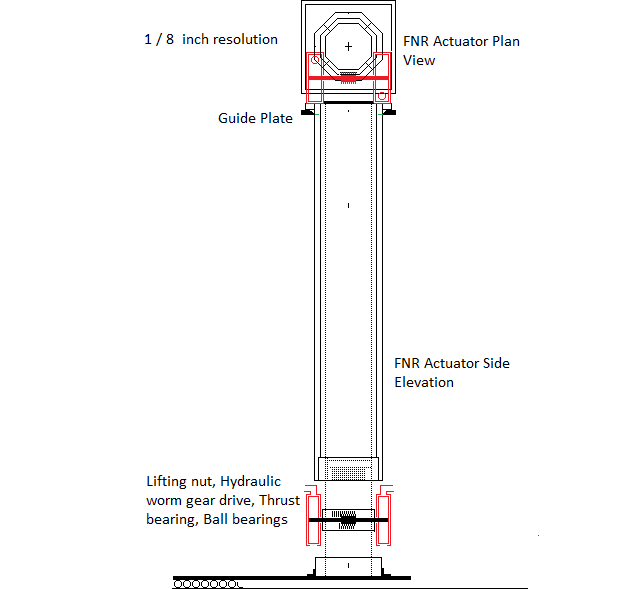

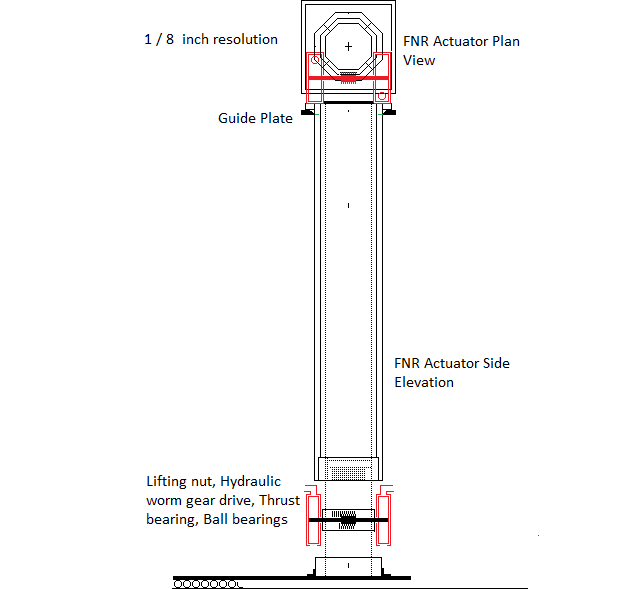

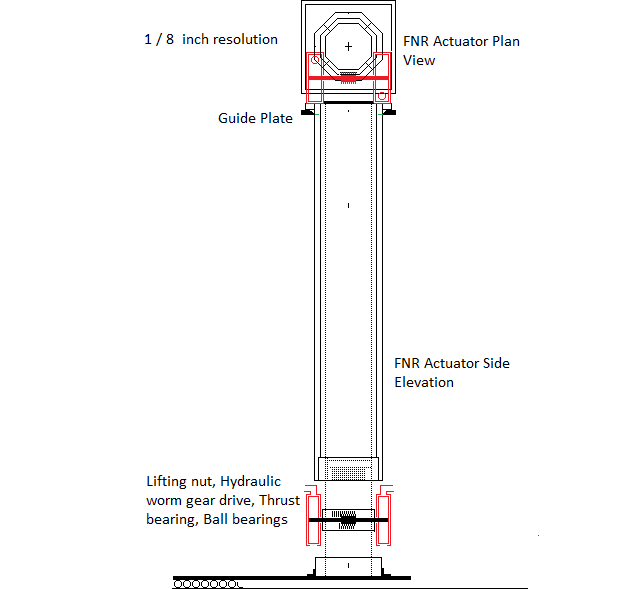

ACTUATOR PLAN VIEW:

In plan view the maximum size of the dedicated actuator space is

[19 X (9 / 16) inch] X [19 X (9 / 16) inch]

= 0.2714 m X 0.2714 m

Theactual actuator OD is:

8.625 inch X 0.0254 m / inch = 0.2191 m

HYDRAULIC TUBING:

The hydraulic tubing is (1 / 4) inch ID stainless steel.

This web page last updated November 26, 2025.

| Home | Energy Physics | Nuclear Power | Electricity | Climate Change | Lighting Control | Contacts | Links |

|---|